Metal Casting Market Trends, Size, Share, Analysis, 2024-2032 | IMARC Group

According to the latest report by IMARC Group, titled“ Metal Casting Market : Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032 ”, offers a comprehensive analysis of the industry, which comprises insights on the

global metal casting market. The report also includes competitor and regional analysis, and contemporary advancements in the global market.

The

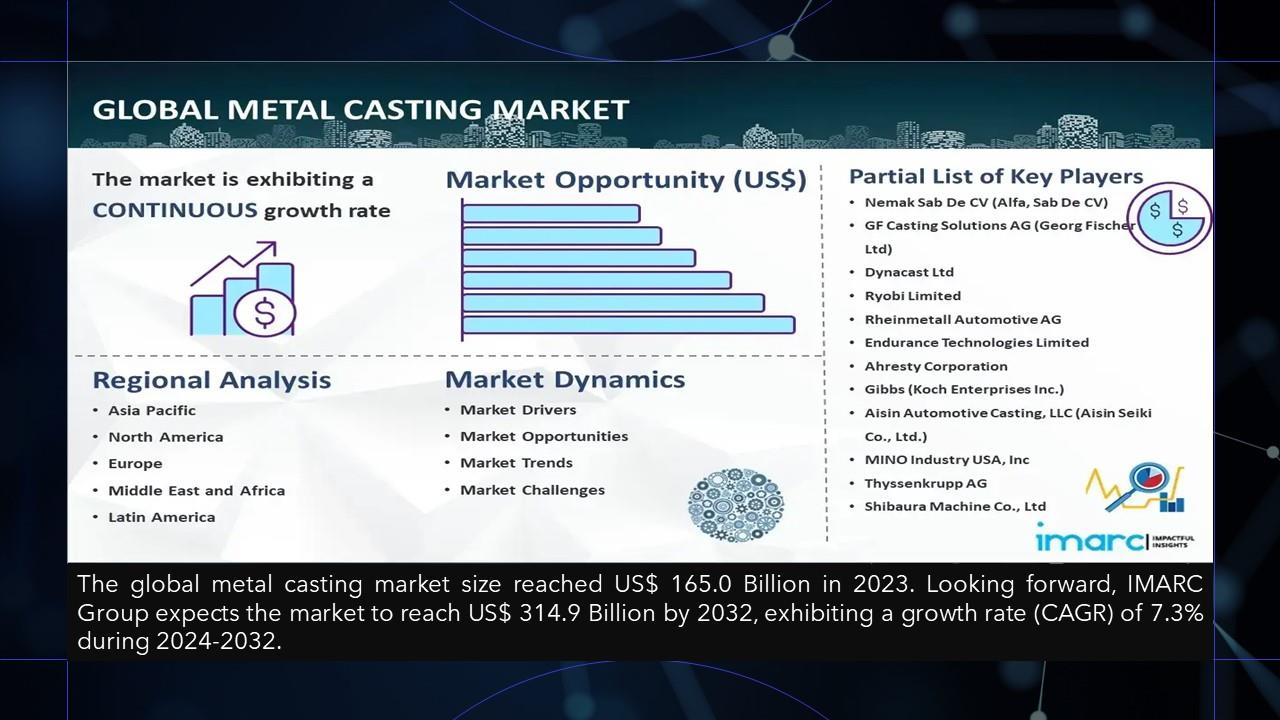

global metal casting market size reached US$ 165.0 Billion in 2023. Looking forward, IMARC Group expects the market to reach US$ 314.9 Billion by 2032, exhibiting a growth rate (CAGR) of 7.3% during 2024-2032.

Metal casting is a manufacturing process that involves pouring molten metal into a mold to create intricate shapes and components. This versatile and ancient technique plays a fundamental role in producing a wide range of metal products, from small and intricate parts to large and complex structures. The process begins with the creation of a mold, typically made of sand or other refractory materials, into which molten metal is poured. Once the metal solidifies and cools, the mold is removed, revealing the final cast metal object.

Metal casting is utilized in various industries, including automotive, aerospace, and construction, due to its ability to produce detailed and customized parts efficiently. This cost-effective and scalable manufacturing method remains integral in shaping the modern world by enabling the mass production of intricate metal components for diverse applications.

Request Free Sample Report: https://www.imarcgroup.com/metal-casting-market/requestsample

Global Metal Casting Market Trends:

The global market is majorly driven by the increasing demand for efficient and cost-effective manufacturing processes. In line with this, the growing automotive industry is significantly contributing to the market growth. From engine components to intricate parts of the chassis, metal casting provides a reliable and scalable method for producing the diverse range of components required in the automotive manufacturing process. The ability to create complex and custom shapes with precision makes metal casting indispensable in meeting the evolving design and performance standards of modern vehicles. Furthermore, the aerospace sector contributes significantly to the growth of the metal casting market.

The demand for lightweight yet strong components in aircraft, such as turbine blades and structural elements, drives the utilization of metal casting. The process allows for the creation of high-strength, temperature-resistant parts critical to the performance and safety of aircraft. Apart from this, the healthcare sector contributes to market growth, as metal casting is used in the manufacturing of medical devices and equipment. From implantable devices to diagnostic instruments, metal casting provides a reliable method for producing complex and biocompatible components.

Moreover, rapid technological advancements are propelling the market. Innovations in casting techniques, materials, and automation enhance the efficiency, precision, and sustainability of metal casting processes. Advanced simulation tools and computer-aided design (CAD) technologies contribute to the optimization of casting designs, reducing waste and improving overall production efficiency. Besides, the construction industry relies on metal casting for various applications, including the production of structural components, decorative elements, and infrastructure materials.

The versatility of metal casting allows for the creation of customized and intricate designs, meeting both functional and aesthetic requirements in construction projects. Additionally, the global emphasis on renewable energy sources further fuels the market growth. Components for wind turbines, solar panels, and other renewable energy infrastructure often involve intricate metal castings. As the demand for sustainable energy solutions continues to rise, so does the need for precision-engineered components produced through metal casting processes.

Some of the Top Key Players Operating in the Metal Casting Industry are Given Below:

- NEMAK SAB de CV GF Casting Solutions AG Dynacast Ltd. Ryobi Limited Rheinmetall Automotive AG Endurance Technologies Limited Ahresty Corporation Gibbs (Koch Enterprises Inc.) Aisin Automotive Casting, LLC MINO Industry USA, Inc. Thyssenkrupp AG Toshiba Machine Co., Ltd

Key Market Segmentation:

Breakup by Process:

- Gravity Casting High-Pressure Die Casting (HPDC) Low-Pressure Die Casting (LPDC) Sand Casting

Breakup by Material Type:

- Aluminum Cast Iron Magnesium Zinc Others

Breakup by Components:

- Alloy Wheel Battery Housing Clutch Casing Cross Car Beam Crank Case Cylinder Head Others

Breakup by Vehicle Type:

- Passenger Cars Light Commercial Vehicles Heavy Commercial Vehicles

Breakup by Electric and Hybrid Type:

- Hybrid Electric Vehicles (HEV) Plug-In Hybrid Electric Vehicles (PHEV) Battery Electric Vehicles (BEV)

Breakup by Application:

- Body Assemblies Engine Parts Transmission Parts Others

Breakup by Region:

- North America (United States, Canada) Asia Pacific (China, Japan, India, Australia, Indonesia, Korea, Others) Europe (Germany, France, United Kingdom, Italy, Spain, Others) Latin America (Brazil, Mexico, Others) Middle East and Africa (United Arab Emirates, Saudi Arabia, Qatar, Iraq, Other)

Key highlights of the Report:

- Market Performance (2018-2023) Market Outlook ( 2024-2032 ) COVID-19 Impact on the Market Porter's Five Forces Analysis Historical, Current and Future Market Trends Market Drivers and Success Factors SWOT Analysis Structure of the Market Value Chain Analysis Comprehensive Mapping of the Competitive Landscape

Note: If you need specific information that is not currently within the scope of the report, we can provide it to you as a part of the customization.

About Us

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC's information products include major market, scientific, economic, and technological developments for business leaders in pharmaceutical, industrial, and high-technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology, and novel processing methods are at the top of the company's expertise.

Contact US

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email:

Tel No:(D) +91 120 433 0800

Americas:- +1 631 791 1145 | Africa and Europe :- +44-702-409-7331 | Asia: +91-120-433-0800

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment