(MENAFN- GlobeNewsWire - Nasdaq) TORONTO, Nov. 20, 2024 (GLOBE NEWSWIRE) -- Xanadu Mines Ltd (ASX: XAM, TSX: XAM) ( Xanadu or the Company ) is pleased to announce strong surface copper assay results from its Sant Tolgoi Project located in Zavkhan Province of Western Mongolia ( Figures 1 and 2 ). Geological mapping, surface rock-chip sampling and geophysics have confirmed the preference of several large anomalies associated with outcropping mafic intrusions. The objective of the multi-discipline exploration programme is to collect the data required to identify drill targets within the large Sant Tolgoi Intrusive Complex. Four targets have been identified and a total of 3000m of reconnaissance drilling has been planned to test all targets for high-grade massive sulphide copper and nickel. Highlights

Reconnaissance rock-chip samples collected at the Sant Tolgoi project have returned high-grade results of up to 2.1% Cu from multiple gossan outcrops Detailed mapping, geophysics and geochemistry defines at least 4 high-priority drill targets over a 4-kilometre-long splay off the Khangai Fault System Follow-up drilling to commence in Q2 2025

Xanadu's VP Exploration, Dr Andrew Stewart, said :

“We are very excited about the latest results from the Sant Tolgoi exploration program which was designed to collect data required to identify drill targets. Our exploration strategy at Sant Tolgoi focuses on outcropping mafic intrusions where anomalous assay results and detailed geophysics has defined four targets within 100-metres of surface.

“This project represents an exciting greenfields opportunity, and is potentially a new Magmatic Cu and possibly Ni-PGE District in an under-explored mineral province of Western Mongolia. These latest results validate and refine our exploration models providing our exploration team with a clear direction towards a significant discovery at Sant Tolgoi. Follow up drilling is planned for the first half of 2025.”

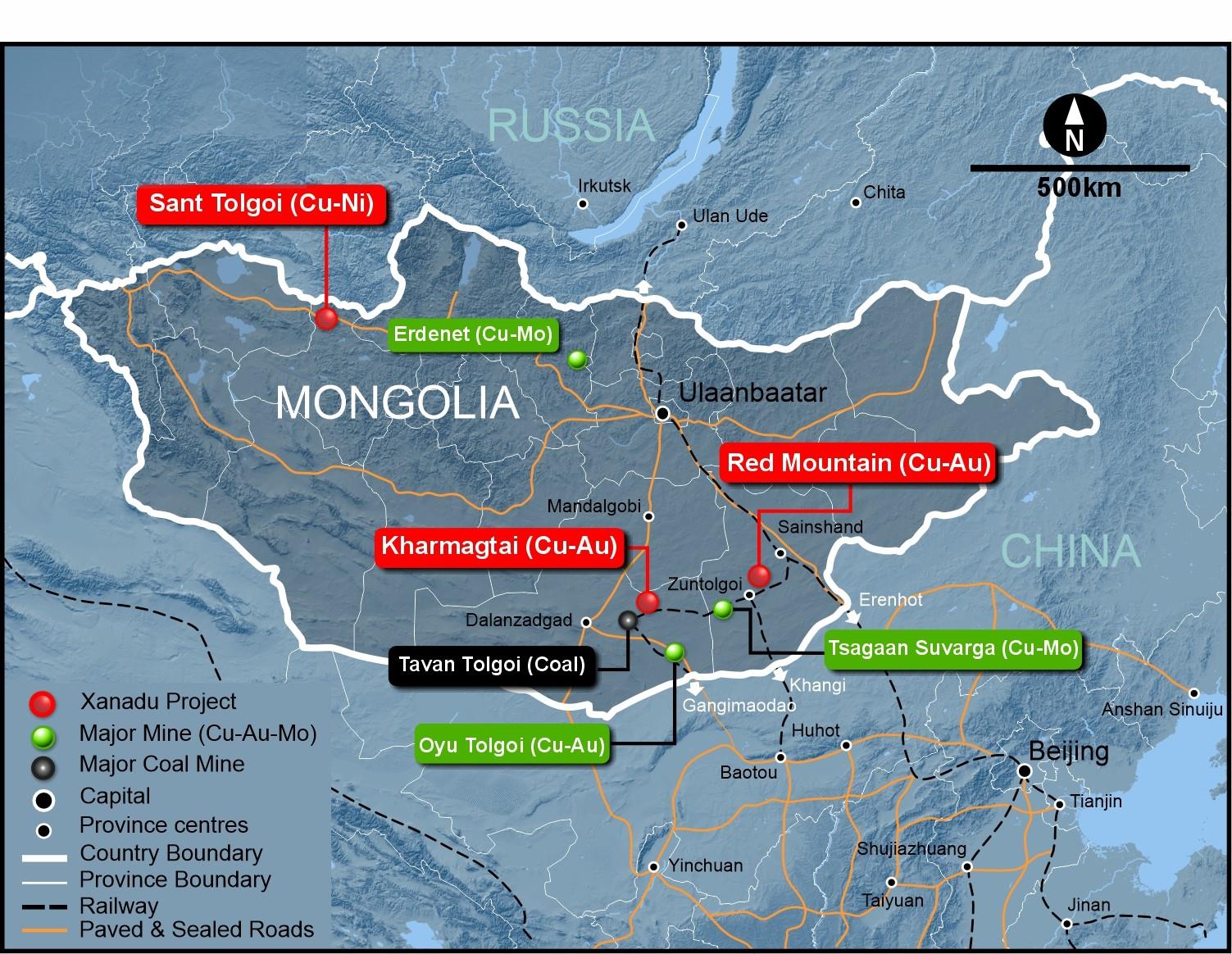

Figure 1: The Sant Tolgoi located in the Zavkhan Province of Western Mongolia.

High-Priority Targets Identified

Four key targets have been identified, based firstly on favourable geology and co-incident strong geochemistry, supported by the geophysical properties indicative of mineral deposits.

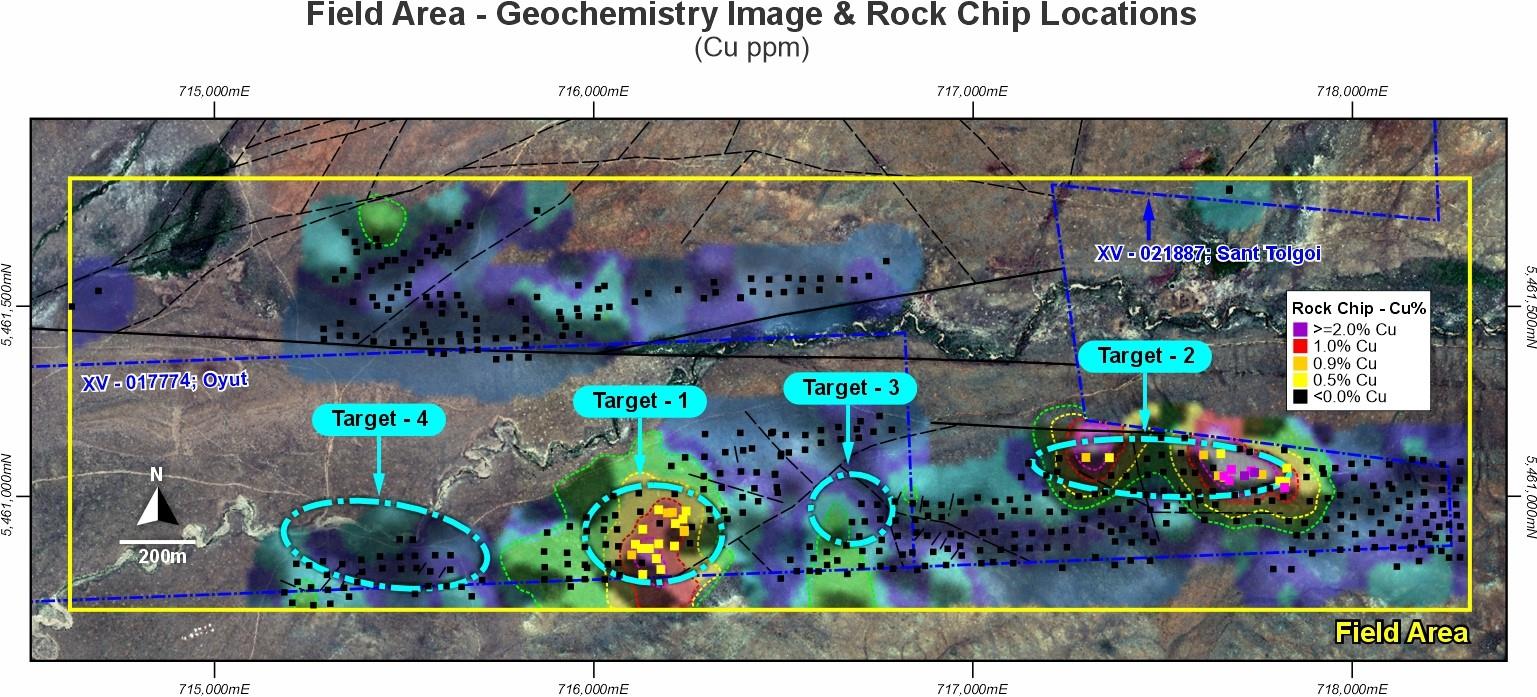

Geochemistry defined four distinct copper targets at surface. Target 1 consists of outcropping copper oxides (Malachite and Azurite) up to 1% copper in assays with mineralisation associated with coarse grained gabbro stock covering a 500m x 300m area. This area sits within a fault jog on a splay off the Khangai Fault System, where dilation could have created space for mineralised intrusions. Magnetics show a strong remanent magnetic feature in 3D suggesting the target consists of an intrusive rock, or rock that has been altered or mineralised by hydrothermal fluids. Gravity data shows a strong density contrast with surrounding rocks, indicative of a denser, potentially mineralised intrusive. A Dipole-Dipole Induced Polarisation (DDIP) line that crossed the target shows a relatively strong 20mV/V IP chargeability anomaly directly below the geochemistry, indicative of disseminated sulphides in a mineralised intrusive. Controlled source audio-frequency magnetotellurics (CSAMT) data also shows a conductive zone associated with the center of this Induced Polarisation (IP) Chargeability anomaly, potentially massive sulphide, surrounded by a resistive halo.

Target 2 is outcropping copper (up to 2.1% Cu) mineralisation associated with coarse grained gabbro sill like body along the structure and covering a 300m x 50m area. Magnetics show a moderate remanent magnetic feature in 3D suggesting the target consists of an intrusive rock, or rock that has been altered or mineralised. Gravity data shows a strong density contrast with surrounding rocks, indicative of a denser, potentially mineralised intrusive. A DDIP line that crossed the target shows a moderate 17mV/V IP chargeability anomaly directly below the geochemistry, indicative of disseminated sulphides. CSAMT data also shows a conductive zone, potentially massive sulphide in an intrusive.

Target 3 is a blind geophysical target under the cover. Target has high density and moderate magnetic features similar with targets have outcropping copper mineralization. The size of anomaly is 300m x 200m.

Target 4 is a blind geophysical target. Target has high density and moderate magnetic features similar with targets have outcropping copper mineralisation. The size of anomaly is 400m x 300m.

Geochemistry Sampling Results

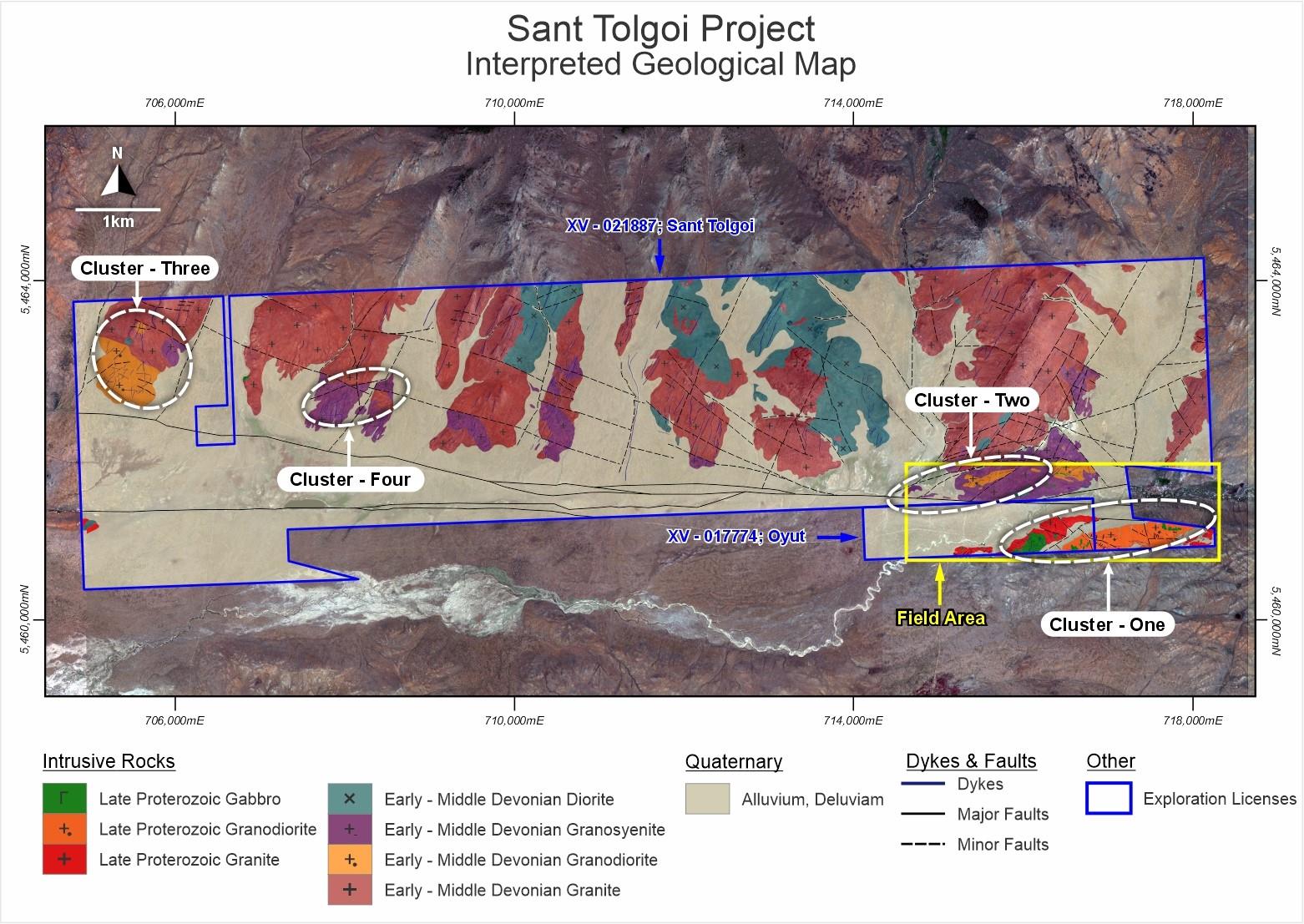

The Sant Tolgoi surface sampling programme consisted of 519 surface rock-chip samples. Sampling was conducted over a 3km by 1km area (Field Area, Figure 2 ) covering two clusters of prospective rocks adjacent to the regional scale Khangai Fault System, interpreted to be channelling mineralisation in the area. Each sample consisted of numerous golf ball sized chips taken from a 2m-by-2m area. These samples identified outcropping copper mineralisation associated with coarse grained (1cm to 2cm grain size) gabbro dykes and stocks ( Figures 2 and 3 ). Results confirm four distinct targets sitting in a 4-kilometre-long splay off the Khangai Fault System with elevated grade of copper up to 2.1% Cu and with association of <4g/t Ag; and <0.06% Ni at surface ( Figure 3 ).

Figure 2 : Interpreted Geology Sant Tolgoi and Field Area Highlighted.

Figure 3: Field Area Copper rock-chip results.

Geophysical Programme

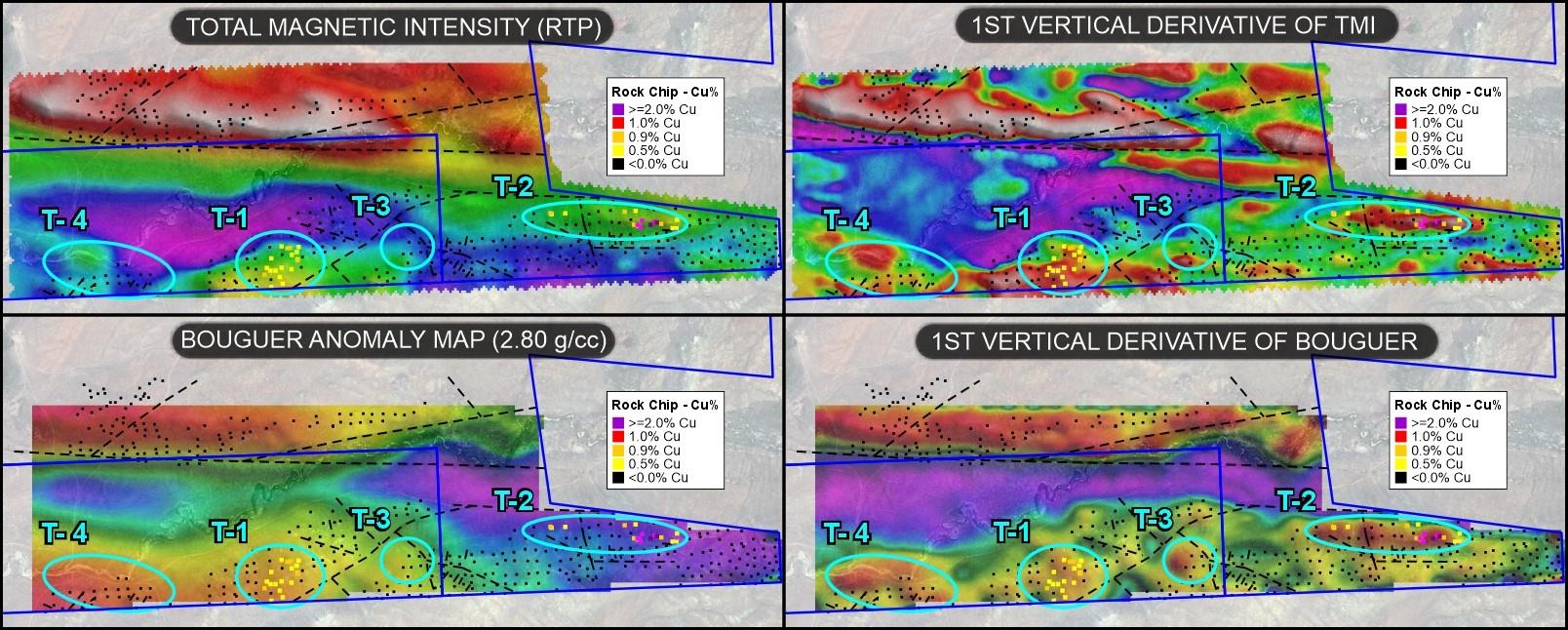

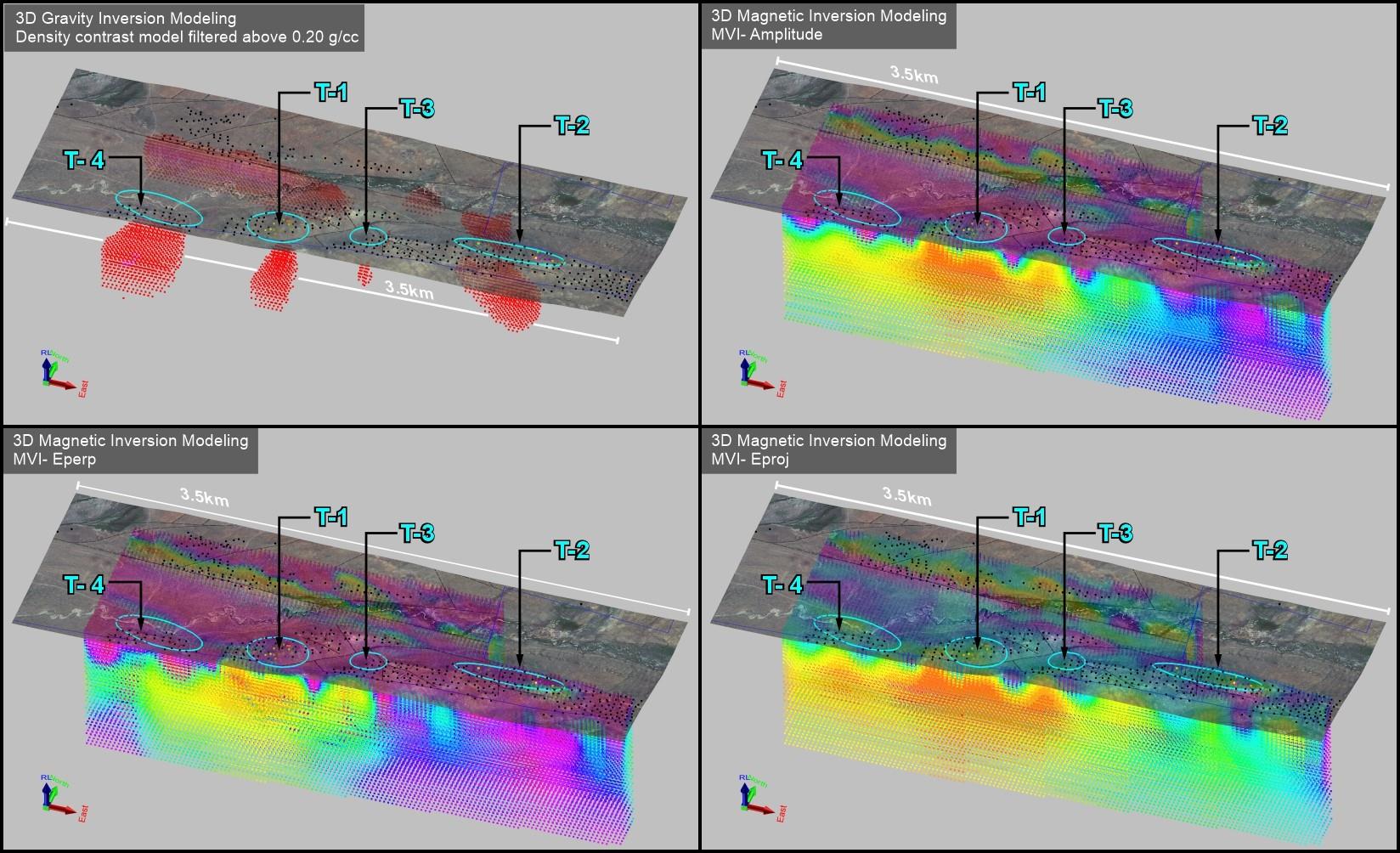

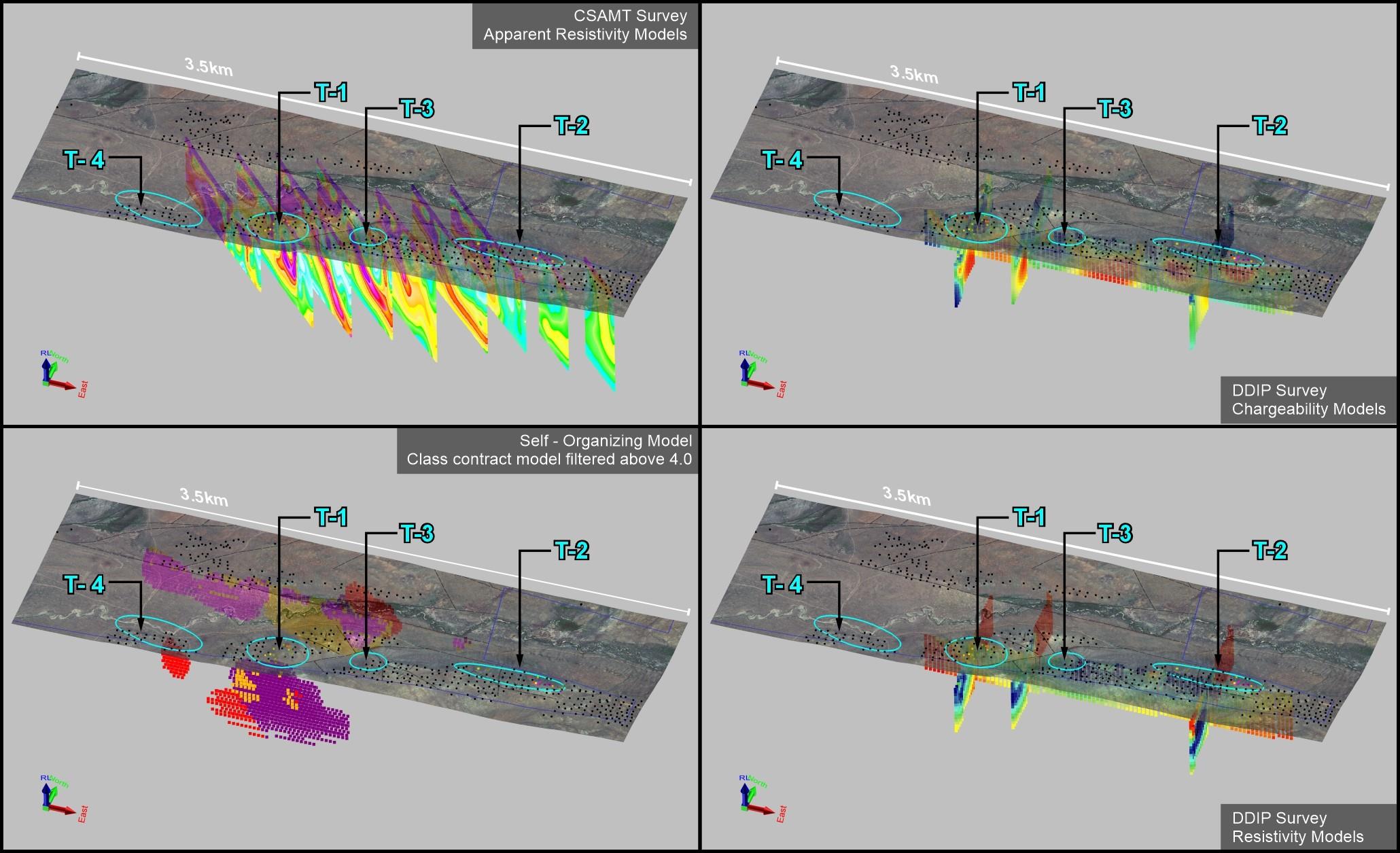

Four geophysical properties have been measured to support drill targeting of surface geological and geochemical data. Magnetic data has been acquired to help identify and separate different rock types at depth. Gravity data has been acquired to potentially map denser intrusive bodies. CSAMT has been acquired to map conductivity which may correlate with linked sulphides (massive and veined) or structures containing water/conductive geological units. Dipole-Dipole Induced Polarisation data has been collected to identify disseminated sulphides ( Figures 4 and 5 ).

Figure 4: Magnetic and Gravity Data. Top two panels show magnetic data, bottom two panels show gravity data.

Figure 5: Magnetic Inversions. See text for descriptions.

A total of 53-line kilometres of drone-based magnetics has been completed across the target area ( Figure 4 ). This data has been inverted in 3D and processed to separate out the three component magnetic vector data. Amplitude data from the three components maps the true location of the magnetic susceptibility feature. The E-perpendicular component maps the remanent magnetic changes which occur after the host rock was formed. Processes like intrusives, alteration or mineralisation. The E-Projected component maps the background geology.

A total 530 stations of ground gravity survey completed over potential prospects of Sant Tolgoi Project. A moderate to high dense domains mapped the distribution of mineralized gabbro stocks or sills ( Figure 4 ).

A total of 9 lines or 150 stations of CSAMT was completed over potential prospects of Sant Tolgoi Project. A low resistivity (conductive) feature mapps the gabbro stocks or sills in depth ( Figure 5 ).

A total 4-line kilometres Dipole-Dipole Induced Polarisation survey completed over potential prospects of Sant Tolgoi Project. High chargeable and low resistivity features endorsing the above geophysics results in depth, where defined gabbro stock or sills ( Figure 5 ).

Figure 5: CSAMT and IP inverted Data as lines.

Geology and Mineralisation

Mineralisation at Sant Tolgoi consists of copper oxides hosted within coarse grained gabbro. Copper is expressed as secondary, remobilised by weathering in fractures and as staining. This is interpreted to have been remobilised from primary disseminated and massive sulphides below the weathering profile. Figures 6 and 7 show polished slab photographs of the coarse-grained hornblende gabbro.

Figure 6: Sample 140866: Coarse-grained, malachite-azurite stained hornblende gabbro.

Sample returned an assay of 0.63% Cu.

Figure 7: Sample 140869: Coarse-grained, malachite-azurite-stained hornblende gabbro.

The sample returned an assay of 0.76% Cu.

About Sant Tolgoi

The Sant Tolgoi Project covers two Exploration Licences, XV-17774 (Oyut) and XV-21887 (Sant Tolgoi) in the Zavchan Province of Western Mongolia with a combined area of over 40km2 ( Figure 2 ), collectively referred to as the Sant Tolgoi Project or Sant Tolgoi Copper Project. The Tenement portfolio includes numerous advanced exploration targets with real prospectivity for the discovery of significant magmatic copper and nickel mineralisation. In the Zavchan Region of Mongolia, the Sant Tolgoi Project lies on the western extension to the of the deep seated Khangai Fault systems, a metalliferous fault network which hosts several significant mafic and ultramafic intrusions that are highly encouraging for intrusion hosted copper and nickel discoveries. Early signs of several copper-nickel systems have been encountered in both historical drilling.

Statements and Disclaimers

Competent Person Statement

The information in this announcement that relates to exploration results is based on information compiled by Dr Andrew Stewart, who is responsible for the exploration data, comments on exploration target sizes, QA/QC and geological interpretation and information. Dr Stewart, who is an employee of Xanadu and is a Member of the Australasian Institute of Geoscientists, has sufficient experience relevant to the style of mineralisation and type of deposit under consideration and to the activity he is undertaking to qualify as the Competent Person as defined in the 2012 Edition of the Australasian Code for Reporting Exploration Results, Mineral Resources and Ore Reserves and the National Instrument 43-101. Dr Stewart consents to the inclusion in the report of the matters based on this information in the form and context in which it appears.

Forward-Looking Statements

Certain statements contained in this Announcement, including information as to the future financial or operating performance of Xanadu and its projects may also include statements which are 'forward‐looking statements' that may include, amongst other things, statements regarding targets, estimates and assumptions in respect of mineral reserves and mineral resources and anticipated grades and recovery rates, production and prices, recovery costs and results, capital expenditures and are or may be based on assumptions and estimates related to future technical, economic, market, political, social and other conditions. These 'forward-looking statements' are necessarily based upon a number of estimates and assumptions that, while considered reasonable by Xanadu, are inherently subject to significant technical, business, economic, competitive, political and social uncertainties and contingencies and involve known and unknown risks and uncertainties that could cause actual events or results to differ materially from estimated or anticipated events or results reflected in such forward‐looking statements.

Xanadu disclaims any intent or obligation to update publicly or release any revisions to any forward‐looking statements, whether as a result of new information, future events, circumstances or results or otherwise after the date of this Announcement or to reflect the occurrence of unanticipated events, other than required by the Corporations Act 2001 (Cth) and the Listing Rules of the Australian Securities Exchange ( ASX ) and Toronto Stock Exchange ( TSX ). The words 'believe', 'expect', 'anticipate', 'indicate', 'contemplate', 'target', 'plan', 'intends', 'continue', 'budget', 'estimate', 'may', 'will', 'schedule' and similar expressions identify forward‐looking statements.

All 'forward‐looking statements' made in this Announcement are qualified by the foregoing cautionary statements. Investors are cautioned that 'forward‐looking statements' are not guarantee of future performance and accordingly investors are cautioned not to put undue reliance on 'forward‐looking statements' due to the inherent uncertainty therein.

About Xanadu Mines

Xanadu is an ASX and TSX listed Exploration company operating in Mongolia. We give investors exposure to globally significant, large-scale copper-gold discoveries and low-cost inventory growth. Xanadu maintains a portfolio of exploration projects and remains one of the few junior explorers on the ASX or TSX who jointly control a globally significant copper-gold deposit in our flagship Kharmagtai project. Xanadu holds 50-50 JV share with Zijin Mining Group in Khuiten Metals Pte Ltd, which controls 76.5% of the Kharmagtai project.

For further information on Xanadu, please visit: or contact:

Colin Moorhead

Executive Chairman & Managing Director

P: +61 2 8280 7497

E: ...

W:

This Announcement was authorised for release by Xanadu's Executive Chair & Managing Director.

APPENDIX 1: Rock Chip Assay Results

Set out below is Section 1 and Section 2 of Table 1 under the JORC Code, 2012 Edition for the Sant Tolgoi project. Data provided by Xanadu. This Table 1 is the first JORC Table 1 disclosure for the Sant Tolgoi Project.

| Criteria | JORC Code explanation | Commentary |

| Sampling techniques | Nature and quality of sampling (e.g. cut channels, random chips, or specific specialised industry standard measurement tools appropriate to the minerals under investigation, such as down hole gamma sondes, or handheld XRF instruments, etc). These examples should not be taken as limiting the broad meaning of sampling. | Samples were taken as surface rock chip samples. 3kg of material was collected using geological hammer as numerous small golf ball sized chips over a 2m-by-2m area. Samples were collected on a rough 50m- by-50m grid over areas of interest. Samples were selected from as many rock types as possible. |

| Drilling techniques | Drill type (e.g. core, reverse circulation, open-hole hammer, rotary air blast, auger, Bangka, sonic, etc.) and details (e.g. core diameter, triple or standard tube, depth of diamond tails, face-sampling bit or other type, whether core is oriented and if so, by what method, etc). | No drilling has been completed on the project. |

| Drill sample recovery | Method of recording and assessing core and chip sample recoveries and results assessed. Measures taken to maximise sample recovery and ensure representative nature of the samples. Whether a relationship exists between sample recovery and grade and whether sample bias may have occurred due to preferential loss/gain of fine/coarse material. | No drilling has been completed on the project. |

| Logging | Whether core and chip samples have been geologically and geotechnically logged to a level of detail to support appropriate Mineral Resource estimation, mining studies and metallurgical studies. Whether logging is qualitative or quantitative in nature. Core (or costean, channel, etc) photography. The total length and percentage of the relevant intersections logged. | No drilling has been completed. Geological data was recorded for each rock chip sample and 1:20,000 and 1:2,000 scale geological mapping was completed over the areas of interest. |

| Sub-sampling techniques and sample preparation | If core, whether cut or sawn and whether quarter, half or all core taken. If non-core, whether riffled, tube sampled, rotary split, etc and whether sampled wet or dry. For all sample types, the nature, quality and appropriateness of the sample preparation technique. Quality control procedures adopted for all sub-sampling stages to maximise representivity of samples. Measures taken to ensure that the sampling is representative of the in situ material collected, including for instance results for field duplicate/second-half sampling. Whether sample sizes are appropriate to the grain size of the material being sampled. | No drilling has been completed on the project. The nature of the sampling (many small golf ball sized pieces of rock being collected over a 2m by 2m sized area) ensures the most representative sample can be collected for the grain-size of the host rocks as possible. One standard and one blank sample inserted for every 40 samples collected. OREAS-680 (Ni-Cu-PGE gabbronorite) standard with 160ppb Au, 218ppb Pd, 405ppb Pt, 0.9% Cu and 2.15% Ni. The blank sample was OREAS 24D (Basalt blank pulp) blank with <1ppb Au, 43.2ppm Cu and 137ppm Ni. |

| Quality of assay data and laboratory tests | The nature, quality and appropriateness of the assaying and laboratory procedures used and whether the technique is considered partial or total. For geophysical tools, spectrometers, handheld XRF instruments, etc, the parameters used in determining the analysis including instrument make and model, reading times, calibrations factors applied and their derivation, etc. Nature of quality control procedures adopted (eg standards, blanks, duplicates, external laboratory checks) and whether acceptable levels of accuracy (ie lack of bias) and precision have been established. | All samples were routinely assayed by ALS Mongolia for gold, multielement, oxides and by ALS Australia for PGE's. Au is determined using a 30g fire assay fusion, cupelled to obtain a bead, and digested with Aqua Regia, followed by an atomic absorption spectroscopy (AAS) finish, with a lower detection (LDL) of 0.005 ppm. (ALS code Au-AA23). All samples were also submitted to ALS Mongolia for the 33-element package ME-ICP61 using a four acid digest (considered to be an effective total digest for the elements relevant to the MRE). Where copper is over-range (>1% Cu), it is analysed by a second analytical technique (Cu-OG62), which has a higher upper detection limit (UDL) of 5% copper. (ALS code ICP-ME61). PGE is determined by ALS Australia using a 30g fire assay fusion and inductively coupled plasma, followed by an atomic emission spectroscopy (ICP-AES) finish, with a lower detection (LDL) of 0.005 ppm. (ALS code PGM-ICP23). The selective samples also submitted to ALS Mongolia for trace element and oxides package ME-XRF15b using oxidizing fusion and followed by monochromatic excitation X-ray fluorescence (ME-XRF) spectrometry (ALS code ME-XRF15b). Quality assurance has been managed by insertion of appropriate Standards (1:20 samples – suitable Ore Research Pty Ltd certified standards), Blanks (1:20 samples). Assay results outside the optimal range for methods were re-analysed by appropriate methods. Ore Research Pty Ltd certified copper and nickel standards have been implemented as a part of QC procedures, as well as certified pulp blanks,. QC monitoring is an active and ongoing processes on batch-by-batch basis by which unacceptable results are re-assayed as soon as practicable. |

| Verification of sampling and assaying | The verification of significant intersections by either independent or alternative company personnel. The use of twinned holes. Documentation of primary data, data entry procedures, data verification, data storage (physical and electronic) protocols. Discuss any adjustment to assay data. | All assay data QAQC is checked prior to loading into XAM's Geobank data base. The data is managed by XAM geologists. The database and geological interpretation is managed by XAM. There have been no adjustments to any of the assay data. |

| Location of data points | Accuracy and quality of surveys used to locate drill holes (collar and down-hole surveys), trenches, mine workings and other locations used in Mineral Resource estimation. Specification of the grid system used. Quality and adequacy of topographic control. | Rock Chip samples were located using a handheld GPS. The grid system used for the project is UTM WGS-84 Zone 46N. The drone magnetic data was located using MagArrow II magnetometer. Gravity data was located using Scintrex CG-5 AutoGrav equipment. |

| Data spacing and distribution | Data spacing for reporting of Exploration Results. Whether the data spacing and distribution is sufficient to establish the degree of geological and grade continuity Whether sample compositing has been applied. | Rock chip samples are spaced approximately 50m by 50m. Drone magnetics was conducted on 40m line spacings. Gravity data was collected on a 40m by 100m grid spacing. Magnetics covers approximately 6.5% of the tenement. Gravity covers approximately 6.5% of the tenement. Rock Chip samples cover approximately 10% of the tenement. |

| Orientation of data in relation to geological structure | Whether the orientation of sampling achieves unbiased sampling of possible structures and the extent to which this is known, considering the deposit type.

| Sampling is opportunistic and conducted on available outcrop. |

| Sample security | The measures taken to ensure sample security. | Samples are dispatched from site in locked boxes transported on XAM company vehicles to ALS lab in Ulaanbaatar. Sample shipment receipt is signed off at the Laboratory with additional email confirmation of receipt. Samples are then stored at the lab and returned to a locked storage site. |

| Audits or reviews | The results of any audits or reviews of sampling techniques and data. | Internal audits of sampling techniques and data management are undertaken on a regular basis, to ensure industry best practice is employed at all times. |

(Criteria in this section apply to all succeeding sections).

| Criteria | JORC Code (Section 2) Explanation | Commentary |

Mineral

tenement

and land

tenure

status | Type, reference name/number, location and ownership including agreements or material issues with third parties such as joint ventures, partnerships, overriding royalties, native title interests, historical sites, wilderness or national park and environmental settings. The security of the tenure held at the time of reporting along with any known impediments to obtaining a license to operate in the area. | The Project comprises 2 Exploration Licences XV-017774 (Oyut) and XV-021887 (Sant Tolgoi). Xanadu now have“Farm-in Deed” with STSM LLC and aims to own 50% of the project afterwards compilation phase II exploration. The Mongolian Minerals Law (2006) and Mongolian Land Law (2002) govern exploration, mining and land use rights for the project. |

Exploration

done by

other

parties | Acknowledgment and appraisal of exploration by other parties. | Previous exploration was conducted by Mongolian and Soviet Geologists. Limited other exploration has been conducted. |

Geology

| Deposit type, geological setting and style of mineralisation. | The mineralisation is characterized as Magmatic Cu-Ni mineralisation. Magmatic Cu-Ni deposits are formed from magmatic hydrothermal fluids typically associated with mafic intrusive stocks or sills that have deposited metals as sulphides both within the intrusive and the intruded host rocks. The disseminated sulphides occurring both within the mafic intrusives and thought out the wall rock. The massive sulphides as lode may occur at the bottom of mafic intrusive bodies. Magmatic Cu-Ni deposits are typically low to high grade, moderate tonnage deposits are generally mined by shallow open pit mining method. The deposits at Sant Tolgoi are a typical in that they are associated with mafic intrusions of gabbro to hornblendite composition. |

Drill hole

Information | A summary of all information material to the understanding of the exploration results including a tabulation of the following information for all Material drill holes: | Rock-Chip data, geological mapping, drone magnetics, gravity, CSAMT and DDIP data are the main sources of data for the project top date. No Drilling has been conducted on the project to date. See figures in ASX/TSX Announcement. |

Data

Aggregation methods | In reporting Exploration Results, weighting averaging techniques, maximum and/or minimum grade truncations (eg cutting of high grades) and cut-off grades are usually Material and should be stated. Where aggregate intercepts incorporate short lengths of high grade results and longer lengths of low grade results, the procedure used for such aggregation should be stated and some typical examples of such aggregations should be shown in detail. The assumptions used for any reporting of metal equivalent values should be clearly stated. | No cut-offs or equivalent metal calculations have been used.

|

Relationship between mineralisation

on widths

and intercept

lengths | These relationships are particularly important in the reporting of Exploration Results. If the geometry of the mineralisation with respect to the drill hole angle is known, its nature should be reported. If it is not known and only the down hole lengths are reported, there should be a clear statement to this effect (eg 'down hole length, true width not known'). | No drilling has been conducted. No intervals have been reported. |

| Diagrams | Appropriate maps and sections (with scales) and tabulations of intercepts should be included for any significant discovery being reported These should include, but not be limited to a plan view of drill hole collar locations and appropriate sectional views. | See figures in ASX/TSX Announcement. |

Balanced

Reporting | Where comprehensive reporting of all Exploration Results is not practicable, representative reporting of both low and high grades and/or widths should be practiced to avoid misleading reporting of Exploration Results. | A full spreadsheet of the assay results received to date has been included in the body of the report. |

Other

substantive

exploration

data | Other exploration data, if meaningful and material, should be reported including (but not limited to): geological observations; geophysical survey results; geochemical survey results; bulk samples – size and method of treatment; metallurgical test results; bulk density, groundwater, geotechnical and rock characteristics; potential deleterious or contaminating substances. | Limited work in this area has been done in the tenement. |

Further

Work | The nature and scale of planned further work (eg tests for lateral extensions or depth extensions or large-scale step-out drilling). Diagrams clearly highlighting the areas of possible extensions, including the main geological interpretations and future drilling areas, provided this information is not commercially sensitive. | |

Mineral Resources are not reported so this is not applicable to this report.

Ore Reserves are not reported so this is not applicable to this report.