Kawasaki Robotics Unveils New Collaborative Robot Designed In Partnership With Neura Robotics Robotics & Automation News

Kawasaki Robotics will demonstrate new additions to its extensive robotics portfolio, including the new CL Series of intelligent collaborative robots (cobots).

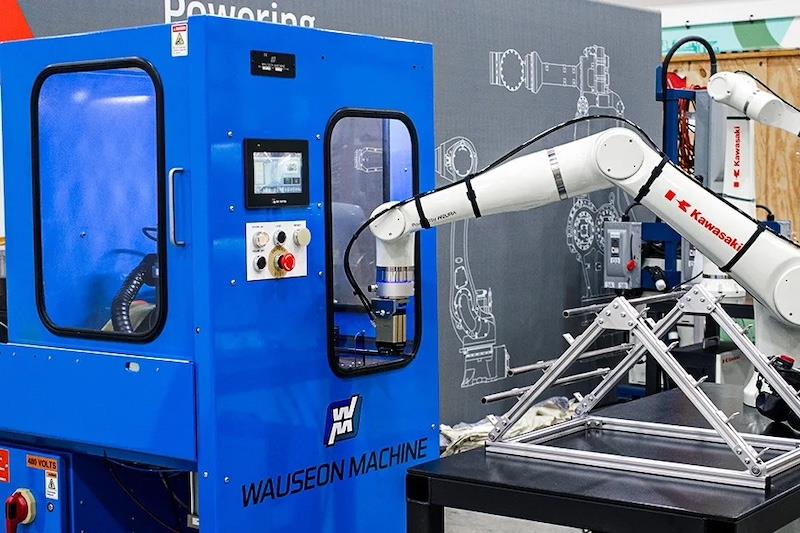

The CL Series cobots, available for order in multiple payloads, and the new industrial robotic solutions featured for applications such as welding, machine tending and material removal give manufacturers limitless flexibility and advanced capabilities when choosing automation to meet their diverse needs.

Seiji Amazawa, president, Kawasaki Robotics, says:“Kawasaki Robotics is committed to delivering the advanced automation technology manufacturers need to maintain production schedules without having to compromise quality or safety.

“We lead the robotics industry by collaborating with innovative partners such as AMT, Hurco, Wauseon Machine and Neura Robotics , integrating our technology with theirs to harness the best in human ingenuity.”

Developed in partnership with Neura Robotics, the CL Series cobots challenge the current understanding of collaborative robots, offering full-on industrial scale performance and speed paired with maximum protection without compromising the safety and flexibility advantages of human/robot collaboration.

Compact and robust, using the same durable casing as Kawasaki Robotics' industrial robot arms, the CL Series cobots can operate without protective covers in crowded and harsh environments that may not be suitable for other cobots.

Operating in Zero Gravity (Zero G), the CL Series cobots require only light guidance and precise adjustments by hand to create highly efficient solutions for applications such as machine tending and welding.

Amazawa says:“With our CL Series cobots, we're entering a new era of collaborative automation. By providing advanced capabilities along with industrial scale performance and speed as standard features, we boost productivity, improve product quality and worker safety, and reduce rework requirements.

“Our entirely new way and agile approach to collaborative robots enables manufacturers to more easily address labor shortages while yielding excellent return on investment.”

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment