Who's Afraid Of TSMC's Management Culture?

an excellent investigative report

into the culture clashes and growing pains at the TSMC factory in Phoenix, Arizona.

Before I dive in, however, I should note that in my opinion, the headline that the magazine gave to this article was not very representative of what's actually going on. The headline is“TSMC's debacle in the American desert,” but the plant so far does

not

look like a debacle.

The TSMC fab was scheduled to begin production in 2024. Most

sources

- including Zhou's article - say that date has been delayed until 2025. But some

recent reports

say that the factory is now

ahead

of schedule and will start production in 2024:

It's possible that TSMC was simply sandbagging in order to make sure they got their CHIPS Act money; the more positive reports came out shortly after the expected subsidy was awarded. It's still not quite clear which dates are correct, and the company itself may not know.

But it's helpful to remember that there was a

huge amount of hubbub

about a dispute between TSMC and Arizona construction unions back in mid-2023 and that a few months later

a settlement was reached

and the dispute evaporated.

So while declaring TSMC's Arizona project a“debacle” might get a lot of attention from people who are ideologically invested in either the failure or the success of US industrial policy, there's a very high chance that this headline turns out in retrospect to be panicky and premature.

That having been said, however, the actual reporting in the article is excellent. There are numerous anecdotes that illustrate the clash in workplace culture and management style between TSMC and the American workforce. Here are just a few excerpts:

Stories like these naturally feed into stereotypes - hard-working respectful East Asians vs lazy Americans who want to be coddled and complimented. And this in turn feeds into the fear that the US just can't compete with East Asian countries in chip manufacturing, or perhaps in any high-tech manufacturing.

But there are many reasons to doubt this conclusion. First, many of the things Americans fear about Taiwanese chip producers are very similar to the things they feared about Japanese manufacturers in general back in the 1980s and early 1990s. But Japanese management turned out to be clunky and inefficient, even in many manufacturing industries.

East Asian management culture doesn't always succeedFrom the late 1970s through the early 1990s, US companies found it hard to compete with Japanese companies in many manufacturing industries, such as cars and electronics. A number of scholars, like

W Edwards Deming

and

Richard T Pascale , attempted to analyze Japanese management techniques for insights that American companies could apply.

But many observers, like

Ezra Vogel ,

Robert Christopher , and even

Akio Morita of Sony , claimed that Japan's performance on manufacturing stemmed from deep-rooted cultural values of hard work, respect for authority, etc - very similar to the Taiwanese cultural values attributed to TSMC by Viola Zhou's interviewees.

It didn't turn out that way. Starting in the 90s, Japan's labor productivity started to

lag significantly

behind that of many other rich countries. In 2007, economists Dale Jorgenson and Koji Nomura did

a detailed industry-by-industry accounting

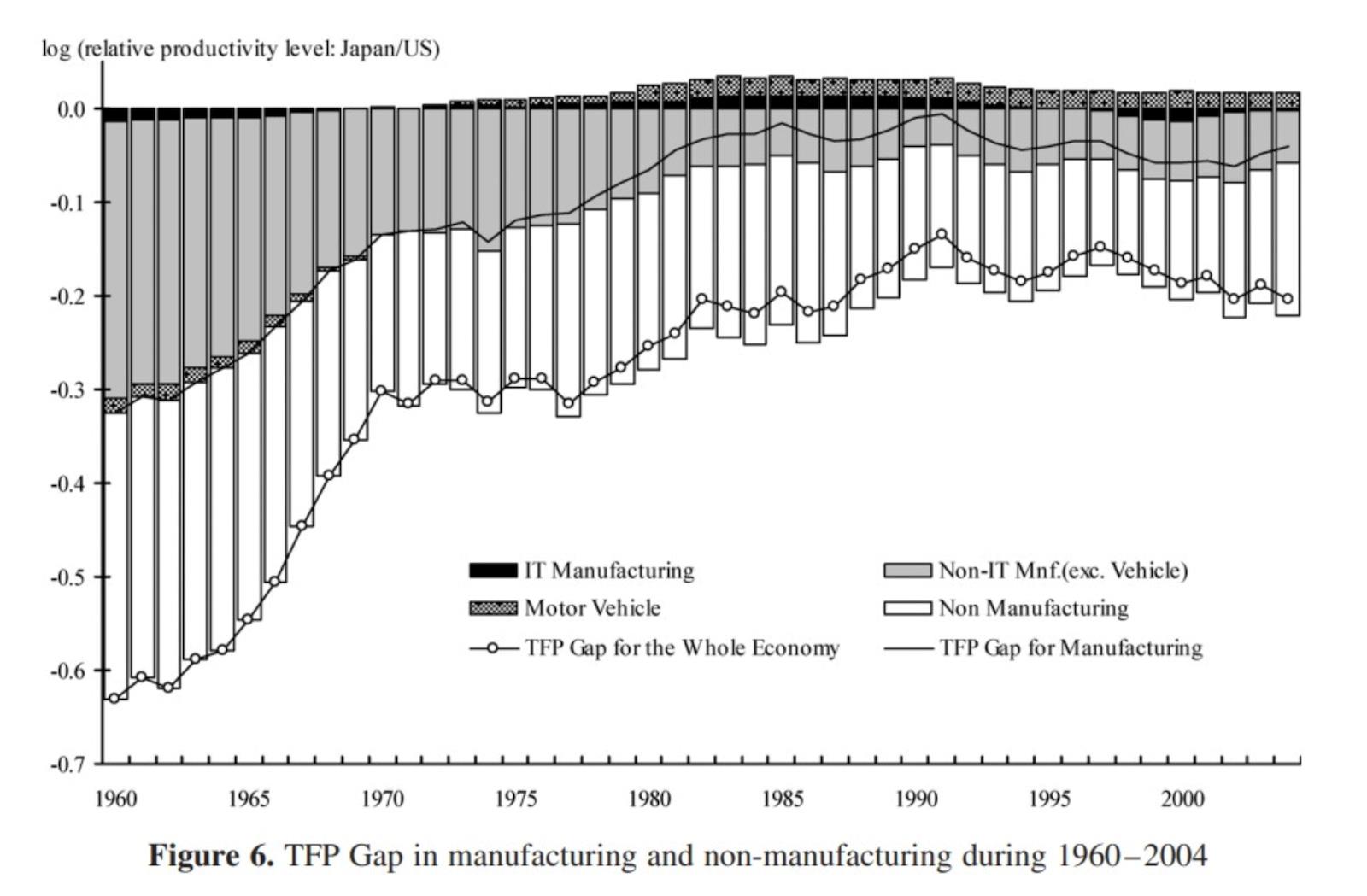

of productivity differences, taking differences in capital investment into account (when you do this, it's called Total Factor Productivity). They found that Japan's manufacturing productivity almost caught up with America's around 1990 and then fell behind again:

Source:

Jorgenson & Nomura (2007)

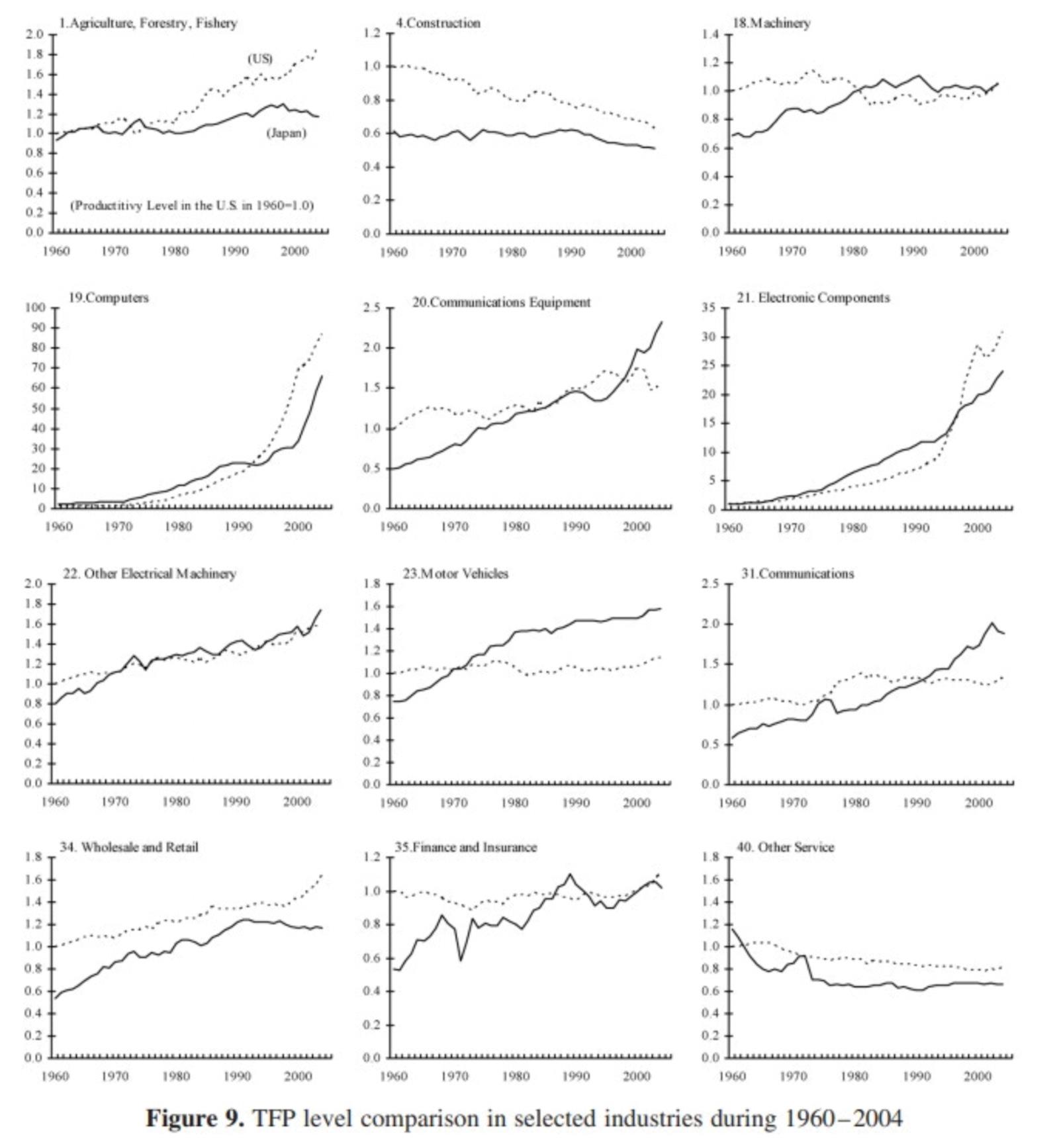

When they broke things down by industry, they found that although Japan did beat the US in some industries, this outperformance sometimes reversed itself over time:

Source:

Jorgenson & Nomura (2007)

Japan had an enduring advantage in motor vehicle manufacturing and opened up a lead in communications equipment in the 90s. But it fell behind in computers and electronic components, and in machinery its advantage evaporated in the 90s.

There are many things that go into TFP - technology, resource costs, regulation, clustering effects, trade, and so on. So we can't just say“Oh, Japanese management culture wasn't so good after all.”

But it's notable that many analyses of Japan's lagging productivity now

explicitly blame

unproductive office culture for part of its poor performance! Working for a Japanese company means long, unproductive hours at the office, trying to look productive for

elderly, entrenched managers .

Useless busy work – sometimes called“presenteeism” –

deprives employees of sleep

and makes them slow and unmotivated. Anecdotally, I have seen examples of this myself in Japanese universities, and my Japanese friends have many similar stories from their companies.

This doesn't mean the cultural essentialists of the 1980s were necessarily wrong. In fact, it's possible that the same values of work-for-work's-sake and respect for corporate hierarchy that were once credited with Japan's manufacturing competitiveness now make it harder to get work done in a white-collar setting.

Now, Taiwanese management culture is different than Japanese management culture, and we can't simply apply the lessons from one country to the other. But here's another interesting example. In 2010, Stan Shih, the founder of the Taiwanese computer manufacturing giant Acer, predicted that US PC brands would be gone in 20 years:

Well, it's only been 14 years, so I suppose Shih still has 6 years left to be right. But as of late 2023, the top three US PC makers still commanded a market share of 45.4%, compared to 37% for China and Taiwan's top three brands combined, with Acer at only 6.4%:

Source:

Wikipedia

The East Asian electronics cluster is formidable but not invincible. In fact, Viola Zhou's story about TSMC dropped some hints that the company's management culture isn't quite as efficient as you might think:

Iran is gaining credibility across the Muslim world

Xi's big adventure to keep Europe open and onside

What Trump's 'America First' would mean for the world

Five former employees from the US told

Rest of World

that TSMC engineers sometimes falsified or cherry-picked data for customers and managers. Sometimes, the engineers said, staff would manipulate data from testing tools or wafers to please managers who had seemingly impossible expectations.

Other times, one engineer said,“because the workers were spread so thin, anything they could do to get work off their plate they would do.”

Four American employees described TSMC culture as“save face”: Workers would strive to make a team, a department or the company look good at the expense of efficiency and employee wellbeing.

Pointless busy work just to please the boss? Hmm, I've heard that story before.

Kyle Chan, writer of the blog High Capacity, had

some interesting thoughts on the matter :

Which brings me to my next point.

Management or macroeconomics?TSMC is certainly one of the world's most successful companies - a true national champion, and a major victory for

industrial policy . But there are a number of reasons why its success relative to American chipmakers, as well as its struggles in the US market, might depend on economic factors outside the company and unrelated to Taiwanese culture.

First of all, much has been made of how TSMC took chip manufacturing market share from Intel, Samsung, and other companies that design and build their own chips in-house.

In addition to whatever Taiwanese cultural factors might be at play, this success is generally attributed to TSMC's“foundry” model - instead of making its own chips, it makes everyone else's chips, allowing it to specialize in the manufacturing process and cross-apply techniques and lessons from one type of product to another.

But you know who else can't make chips as well as TSMC?

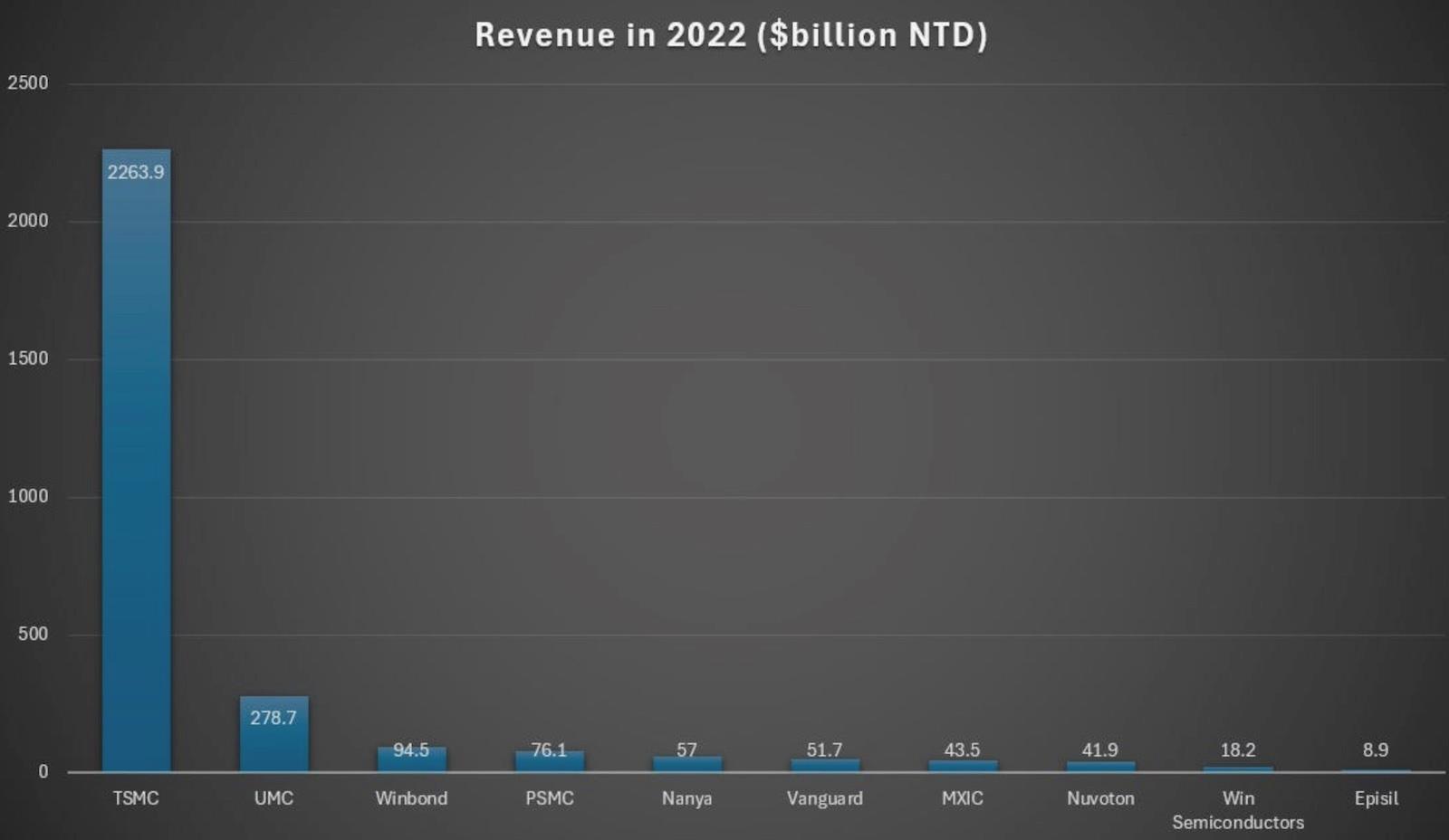

Any other Taiwanese company in existence. If you look at a chart of revenue for chipmakers in Taiwan, it's just TSMC towering over all the rest:

Source: Taiwan Semiconductor Industry Association

All together, TSMC's competitors have only 30% of its revenue. This is why no one is talking about building Winbond factories in Arizona, or discussing whether the US would go to war to protect Nuvoton from a Chinese invasion. Unlike Japanese auto companies in the 80s, or even Taiwanese PC makers in the 2010s, there is precisely

one

top chipmaker in Taiwan.

This is why TSMC pretty much gets its pick of Taiwanese talent, in terms of both skill and work ethic. Other companies don't get this benefit; if you're a top Taiwanese chip engineer, TSMC is just where you go work. So the engineers at TSMC aren't representative of Taiwanese skills and work ethic as a whole; they're a special, hyper-selected elite.

And what's more, TSMC doesn't have to pay very much for these top performers. In 2021,

the median salary at TSMC was US$64,874

in US dollars, with a bonus of

about $40 ,000 for a total of about $105,000.

In the tech world, that's nothing. That's less than an entry-level American software engineer makes right out of college

working for Visa , the credit card company.

Why does TSMC get top workers for such low pay? Well, one big reason is that Taiwanese workers just don't make very much in general. The average salary for full-time employees in Taiwan

is $22,242 . That's less than a minimum-wage worker

makes in Missouri or South Dakota . So in Taiwan, a TSMC salary is fairly big bucks.

Why are wages so low in Taiwan? One reason is that Taiwan is poorer than the United States. Another reason is that Taiwan makes sure to

keep its currency very cheap

relative to the US dollar, probably in order to improve the competitive position of companies like TSMC.

Meanwhile, TSMC's Arizona fabs have to compete for talent against other American tech companies. A typical hardware engineer at Apple gets paid somewhere around

$200,000 to $300,000 ; chip companies tend to pay a bit less, but still more than what TSMC workers get in Taiwan. But it's not just the hardware industry TSMC has to compete with in America; it's the

software

industry too.

A smart young American can choose to learn how to build chips or how to write code; the talent required is not very different. And if they choose to write code, they will generally get paid more. A typical software engineer at Google will get paid around $300k-$400k; for Facebook

it's more like $300k-$500k . (Meanwhile, try naming a Taiwanese software company.)

And make no mistake: Top American performers often work very, very hard. High earners in America

work hard in general , and many top people are putting in those 70-hour workweeks. Many young lawyers and doctors do this, as do employees at some tech companies

like Tesla , and many company founders and startup employees.

In its heyday under Andy Grove, Intel had

an intense, punishing work culture

not unlike TSMC. But they have to have some special motivation in order to do this - either the promise of a very high salary, or the promise of a big exit for their startup, or at least the pride of working as a doctor or for a prestigious company like Tesla. TSMC gets a lot of headlines, but it's not prestigious in America the way it is in Taiwan.

Even Taiwanese workers in the U.S. are tempted by the lure of better jobs elsewhere, as Zhou's article notes:

That's what TSMC is really competing with at its Arizona fabs. It's having to pay a multiple of what it would pay in Taiwan, for workers who are less elite and less passionately committed to the company.

This is not an advantage of Taiwanese management or Taiwanese culture - it's a function of the fact that Taiwan is a less wealthy country than America, and one that has chosen to throw many of its best people into a single national champion company. Compared to that, of course making chips in Arizona is going to be more expensive.

Americans can learn East Asian manufacturing methods just fineSo far, I've argued that:

- East Asian management culture is not necessarily the best, even if it looks very intense and hard-working, and

- TSMC's cost disadvantages in Arizona depend on macro factors, not just on cultural differences (or perhaps not on cultural differences at all).

But it's also the case that sometimes, East Asian companies come up with important management innovations that really do raise productivity a lot. But when they do,

American workers can learn and apply those innovations

in America.

The prime example here is the Japanese car industry. In the 1980s, Japanese carmakers started exporting a lot fewer cars from Japan to the US, and started making a lot more cars in the US:

Source:

JAMA

Every Japanese carmaker has

huge auto plants in the U S, and many of

the most American-made cars

are built by workers working for Japanese brands.

This was an absolutely massive experiment in foreign direct investment by an East Asian country into the US. At the time, Japanese auto manufacturing productivity was much higher than American productivity, so the Japanese companies had much to teach their American workers.

And teach them they did. American car plants adopted practices such as the kanban scheduling system, the kaizen system of continuous improvement (originally conceived of in the US but put into practice in Japan), and many others.

These practices mostly came from the famous Toyota Production System, but they form the basis of what we now know as

lean manufacturing . Japanese car companies implemented these techniques at their factories in America but they've diffused widely since then - not just to American car companies, but to many other industries throughout corporate America.

American factories were successfully able to learn these Japanese management techniques.

Detailed comparisons

between vehicles built in Japan and those built in the US show only very small differences.

And the cars that Japanese brands build in America are internationally competitive, even in spite of America's uncompetitive exchange rate. Consumers in Korea are

buying Nissan Altimas

made in Tennessee and

Honda Accords

made in Ohio. Australians are

buying Toyota Highlanders

made in Indiana.

If American workers can learn how to build cars like Japan, it seems like a good bet that they can learn to build chips like Taiwan. But Japanese carmakers started trying to teach American workers their tricks in the late 1980s; TSMC has barely started trying. Viola Zhou's article indicates that TSMC isn't even to the stage of being able to

talk

to American workers:

Language barriers are the very earliest thing that companies have to overcome when they build factories overseas. The fact that TSMC still can't even communicate in English means that it's still very early days.

That's why it's so unhelpful to declare that TSMC's factories in America are a“debacle” just because of a modest delay at the outset. Foreign direct investment is a long, winding, arduous journey. It's not the kind of thing where we should expect everything to run perfectly smoothly on the first try.

Meanwhile, the mystique of East Asian culture is just not a good lens through which to view challenges like this one. Cross-country cultural differences are real but they aren't as impactful on business as people like to think. Humans are humans, and they can learn.

This

article

was first published on Noah Smith's Noahpinion

Substack and is republished with kind permission. Read the

original and become a Noahopinion

subscriber

here.

Thank you for registering!

An account was already registered with this email. Please check your inbox for an authentication link.

Sign up for one of our free newsletters

- The Daily ReportStart your day right with Asia Times' top stories AT Weekly ReportA weekly roundup of Asia Times' most-read stories

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment