(MENAFN- PR Newswire)

ATLANTA, Oct. 28, 2024 /PRNewswire/ -- The following is a blog post by Pierre Labat, Senior Vice President Chief Strategy & Sustainability, Novelis

At Novelis, circularity isn't just a buzzword – it's the foundation of everything we do. As the world's largest recycler of aluminum, we've long recognized the critical role that this infinitely1 recyclable material can play in creating a more sustainable future.

Continue Reading

Novelis 3x30

Pierre Labat, Senior Vice President, Chief Strategy and Sustainability Officer, Novelis Inc.

But in today's fast-changing world, we know we need to do more. The urgency to reduce waste, decarbonize industries, and mitigate climate change has never been greater. That's why we're doubling down on our commitment to sustainability with

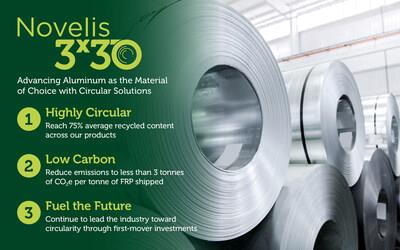

Novelis 3x30 - our new, company-wide vision to advance aluminum as the material of choice with circular solutions and continue to fulfill our company purpose of Shaping a Sustainable World Together like never before.

What Does Circularity Mean at Novelis?

Simply put, circularity is about keeping materials in use for as long as possible. For aluminum, this means creating a closed-loop system where products can be recycled over and over again, without ever losing their quality. The best part? 75% of all aluminum ever produced is still in use today. That's the power of aluminum's infinite recyclability.

At Novelis, we're proud to be part of this circular ecosystem. Our business model centers on using as much recycled aluminum as possible, creating products that can be returned to the production loop over and over again. This helps us reduce the need for primary aluminum, save energy, and significantly cut our carbon emissions.

Introducing Novelis 3x30: Our Next Step in Circularity

With Novelis 3x30, we've set three ambitious goals to further advance circularity and decarbonization by the end of 2030:

Increase Recycled Content to 75%

Right now, 63% of the aluminum we use in our products comes from recycled material. Our goal is to increase that number to 75% by 2030. It's a bold target that will require innovation and collaboration across the industry, but we believe it's achievable. By increasing our recycled content, we can significantly reduce the need for primary aluminum, which uses 95% more energy to produce than recycled material.

Reduce Emissions to Less than 3 Tonnes of CO2e per Tonne of Flat-Rolled Product (FRP) Shipped

While we've already made significant progress in reducing our carbon footprint-27% absolute emissions reduction since FY16-we know there's more work to be done. To better align with the rapid growth of our industry, we're pivoting to an intensity-based carbon reduction goal. This means we aim to emit less than 3 tonnes of CO2e per tonne of FRP by 2030, while continuing to increase our production capacity to meet growing market demand.

Lead the industry with first-mover investments to drive circularity

We believe that staying ahead of the curve in sustainability requires investments in innovation and technology. As part of Novelis 3x30, we are continuing to make bold, forward-thinking investments in new technologies that drive circularity, strengthen our recycling leadership, and decarbonize our operations.

Circularity in Action: Closed-Loop Partnerships and Innovation

Novelis is the largest recycler of aluminum in the world. For example, in the beverage packaging industry, we recycle more than 82 billion aluminum cans each year. These cans can be back on store shelves in as little as 60 days-and this process can be repeated over and over again. This isn't just good for business; it's a vital component of reducing carbon emissions and promoting a circular economy.

One of the ways we're making circularity a reality is through our closed-loop recycling partnerships. We work closely with customers, particularly in the automotive and beverage packaging sectors, to recover their production scrap, return it to our facilities, and reintroduce it into the production process. This reduces waste, preserves valuable aluminum, and ensures that materials stay in use at their highest value for as long as possible.

In addition to closed-loop systems, we're developing new high-recycled-content alloys that should make it easier to incorporate aluminum scrap back into the production process without sacrificing product quality. This kind of innovation is key to pushing the boundaries of what's possible in a circular economy.

Why the Circular Economy Matters

Transitioning to a circular economy is about more than just recycling. It's about fundamentally rethinking how we design, produce, and consume goods to minimize waste and maximize resource efficiency.

By advancing circularity, we can drastically reduce the carbon footprint of entire industries. In fact, recycled aluminum's carbon footprint is 95% less intensive than that of primary aluminum. That's why it's so important that we work together-across industries, supply chains, and governments-to create systems that prioritize recycling and material reuse.

At Novelis, we're committed to being part of that change. We're already leading the way in aluminum recycling, and through Novelis 3x30, we're taking our circularity efforts to the next level. But we know we can't do it alone. Achieving our sustainability goals will require collaboration across the entire value chain.

Shaping a Sustainable World Together

As we look toward 2030 and beyond, one thing is clear: the world needs circular solutions. At Novelis, we're proud to be leading the way in aluminum circularity, and we're excited to continue partnering with our customers, governments, and industry peers to make circularity the norm, not the exception.

By keeping more aluminum "in the loop," we're not just reducing waste; we're creating a more sustainable, lower-carbon future for everyone.

SOURCE Novelis Inc.

WANT YOUR COMPANY'S NEWS FEATURED ON PRNEWSWIRE?

440k+