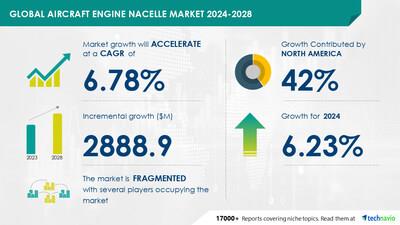

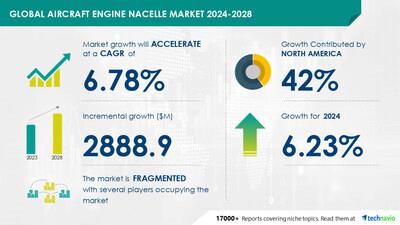

Aircraft Engine Nacelle Market To Grow By USD 2.89 Billion From 2024-2028, Boosted By Advancements In Engine And Nacelle Technology AI Driving Market Transformation - Technavio

| Aircraft Engine Nacelle Market Scope |

|

| Report Coverage |

Details |

| Base year |

2023 |

| Historic period |

2018 - 2022 |

| Forecast period |

2024-2028 |

| Growth momentum & CAGR |

Accelerate at a CAGR of 6.78% |

| Market growth 2024-2028 |

USD 2888.9 million |

| Market structure |

Fragmented |

| YoY growth 2022-2023 (%) |

6.23 |

| Regional analysis |

North America, Europe, APAC, Middle East and Africa, and South America |

| Performing market contribution |

North America at 42% |

| Key countries |

US, China, Germany, France, and UK |

| Key companies profiled |

Adecco Group AG, Aernnova Aerospace SA, Arkwin Industries Inc., Aviagroup Industries, Barnes Group Inc., Bombardier Inc., Cadence Aerospace LLC, DRB HICOM Berhad, FACC AG, Kawak Aviation Technologies Inc., Leonardo Spa, Magellan Aerospace Corp., Melrose Industries Plc, MSM aerospace fabricators Ltd, RTX Corp., Safran SA, Singapore Technologies Engineering Ltd., Spirit AeroSystems Inc., The Nordam Group LLC, and Triumph Group Inc. |

Market Driver

Additive manufacturing, or 3D printing, is revolutionizing the global aircraft engine nacelle market with its ability to create complex engine components. This technology enables the production of intricate geometries and unique shapes, impossible with traditional manufacturing methods. The benefits of additive manufacturing include enhanced performance, lighter weight, and increased durability. These advantages lead to improved fuel efficiency, reduced emissions, and cost savings. By eliminating tooling requirements and minimizing waste, additive manufacturing significantly reduces production costs. As environmental regulations become stricter, the aircraft engine nacelle market will continue to embrace this technology to meet demands for better performance, cost savings, and eco-friendliness.

The Aircraft Engine Nacelle market is witnessing significant trends with the increasing use of advanced materials like composites, titanium alloys, nickel-chromium, stainless steel , and aluminum alloys. Rear-mounted nacelles and pylons under the wing are popular designs. Civil jets, business jets, and military aircraft all require fuel-efficient and noise-reducing nacelles. Nacelles are a vital component, made from hardness and strength-providing nickel alloys and corrosion-resistant materials. Heat-processed forgings and plain carbon steels are also used. Thrust reversers and aircraft deliveries drive demand for component providers and engine providers. New engines and smaller parts require highest demand. Aircraft OEMs and the military sector, including armed forces, have a large fleet of aircraft, driving the market. 3D printing technology and fuel-efficient engines are key trends, with structural enhancements to address fan blade failure and exhaust nozzle reinforcements.

Request Sample

of our comprehensive report now to stay ahead in the AI-driven market evolution!

Market

Challenges

-

Aircraft engine nacelles are essential components that require an airworthiness certificate before being used in commercial aviation. Regulatory bodies like the FAA and EASA impose strict requirements to ensure aircraft safety. Engine maintenance , particularly for nacelles, incurs significant costs for airlines, ranging from less than USD1 million to over USD10 million. These expenses can result from the need for repairs, performance restoration, or overhaul, depending on the engine model and its condition. The latest nacelle systems are primarily made from composite materials, which necessitate non-destructive testing for maintenance. This process is time-consuming and costly, adding to the overall engine maintenance costs. As profit margins in the aviation industry are low, these high nacelle maintenance costs may hinder the growth of the global aircraft engine nacelle market in the forecast period.

Aircraft engine nacelles are vital components that house and protect engines in both commercial and military aircraft. These noise-reducing structures are made from materials like nickel alloys and heat-processed forgings for their hardness, strength, and corrosion-resistant characteristics. New engines require lighter nacelles to reduce the overall weight of aircraft. Small parts like thrust reversers and exhaust nozzles are also being reinforced for improved performance. Component providers and engine manufacturers face challenges in meeting the highest demand from Aircraft OEMs, business jets , and the military sector. The military sector, including armed forces, requires nacelles that can withstand extreme conditions. Fuel efficiency is a major concern, driving the adoption of fuel-efficient engines and structural enhancements. Component providers and engine manufacturers are exploring 3D printing technology to produce lighter and more cost-effective nacelles. The market for aircraft engine nacelles is expected to grow significantly due to increasing aircraft deliveries, passenger traffic, and the development of new engines. Challenges include fan blade failure and the need for reinforcements in fan blades and exhaust nozzles. The flagship supersonic airliner is expected to create new opportunities in the market.

Discover how AI is revolutionizing market trends-

Get your access now!

Segment Overview

This aircraft engine nacelle market report extensively covers market segmentation by

Application-

1.1 Commercial aircraft

1.2 Business aircraft

1.3 Military aircraft

-

2.1 Original equipment manufacturer

2.2 Aftermarket

-

3.1 North America

3.2 Europe

3.3 APAC

3.4 Middle East and Africa

3.5 South America

1.1 Commercial aircraft-

The global aircraft engine nacelle market caters to the commercial aviation sector, which is segmented into narrow-body, wide-body aircraft, and regional jets based on aircraft size and type. Narrow-body aircraft, such as the Boeing 737 and Airbus A320, require nacelles for engines with a thrust range of up to 35,000 pounds (lbs). In contrast, wide-body aircraft like the Boeing 777 and Airbus A350 have larger engines, necessitating nacelles with a thrust range of up to 100,000 pounds (lbs). Regional jets, such as the Embraer E-Jet and Bombardier CRJ series, use nacelles for engines with a thrust range of up to 20,000 pounds (lbs). Furthermore, there are specialized applications of nacelles for military transport and refueling aircraft, which demand nacelles with higher thrust ranges and additional features, including in-flight refueling capabilities, driving growth in the commercial aircraft segment of the global aircraft engine nacelle market.

Download a Sample

of our comprehensive report today to discover how AI-driven innovations are reshaping competitive dynamics

Research Analysis

Aircraft engine nacelles are integral components that house and protect jet engines in commercial aircraft. They are typically made from materials such as composites, titanium alloys, nickel-chromium, stainless steel, and aluminum alloys. Nacelles come in various designs, including rear-mounted and pylons under the wing, clipped at the wingtip. The weight of the aircraft and the size of the engines determine the design and materials used. New engines require lighter and more efficient nacelles to reduce overall aircraft weight and improve fuel efficiency. Small parts such as fan blades and exhaust nozzles are also crucial components of the nacelle system. However, fan blade failure and other issues can lead to costly maintenance and downtime for airlines. Aircraft engine nacelles play a vital role in the performance and safety of commercial aircraft.

Market Research Overview

Aircraft engine nacelles are vital components that house and protect jet engines in both civil and military aircraft. They are typically made of materials such as composites, titanium alloys, nickel-chromium, stainless steel, and aluminum alloys. These materials offer high strength, hardness, and corrosion-resistant characteristics, making them ideal for the harsh operating conditions of jet engines. Rear-mounted nacelles are commonly used in civil jets, while pylons under the wing and clipped at the wing are used in business and private jets. Military aircraft also utilize nacelles for their jet engines, with a focus on fuel efficiency, noise reduction, and structural enhancements. New aircraft and fuel-efficient engines are driving the demand for advanced nacelle technologies. Component providers and engine providers are investing in research and development to produce lighter, stronger, and more efficient nacelles using materials like heat-processed forgings and plain carbon steels. Thrust reversers and reinforcements are also being integrated into nacelles to improve performance and safety. The highest demand for aircraft engine nacelles comes from the civil aviation sector, driven by increasing air passenger traffic and the delivery of new aircraft. The military sector, including the armed forces, also relies on nacelles for their fleet of aircraft. Advancements in 3D printing technology are also contributing to the development of fuel-efficient engines and structural enhancements for nacelles. The upcoming flagship supersonic airliner is expected to feature advanced nacelle technologies to improve fuel efficiency and reduce noise. Overall, aircraft engine nacelles play a crucial role in the performance and safety of modern aircraft.

Table of Contents:

1 Executive Summary

2 Market Landscape

3 Market Sizing

4 Historic Market Size

5 Five Forces Analysis

6 Market Segmentation

-

Application

-

Commercial Aircraft

Business Aircraft

Military Aircraft

-

Original Equipment Manufacturer

Aftermarket

-

North America

Europe

APAC

Middle East And Africa

South America

7 Customer Landscape

8 Geographic Landscape

9 Drivers, Challenges, and Trends

10 Company Landscape

11 Company Analysis

12 Appendix

About Technavio

Technavio is a leading global technology research and advisory company. Their research and analysis focuses on emerging market trends and provides actionable insights to help businesses identify market opportunities and develop effective strategies to optimize their market positions.

With over 500 specialized analysts, Technavio's report library consists of more than 17,000 reports and counting, covering 800 technologies, spanning across 50 countries. Their client base consists of enterprises of all sizes, including more than 100 Fortune 500 companies. This growing client base relies on Technavio's comprehensive coverage, extensive research, and actionable market insights to identify opportunities in existing and potential markets and assess their competitive positions within changing market scenarios.

Contacts

Technavio Research

Jesse Maida

Media & Marketing Executive

US: +1 844 364 1100

UK: +44 203 893 3200

Email:

[email protected]

Website:

SOURCE Technavio

WANT YOUR COMPANY'S NEWS FEATURED ON PRNEWSWIRE? 440k+Newsrooms &

Influencers 9k+

Digital Media

Outlets 270k+

Journalists

Opted In GET STARTED

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment