Creatine Monohydrate Manufacturing Plant Setup Report 2025: Investment Opportunities And Industry Trends

Setting up a creatine monohydrate manufacturing plant requires careful consideration of raw material sourcing, production equipment, quality control systems, and compliance with food and supplement regulations. Key investments include reactors, filtration units, drying systems, and packaging machinery, along with skilled technical staff to ensure purity and safety standards.

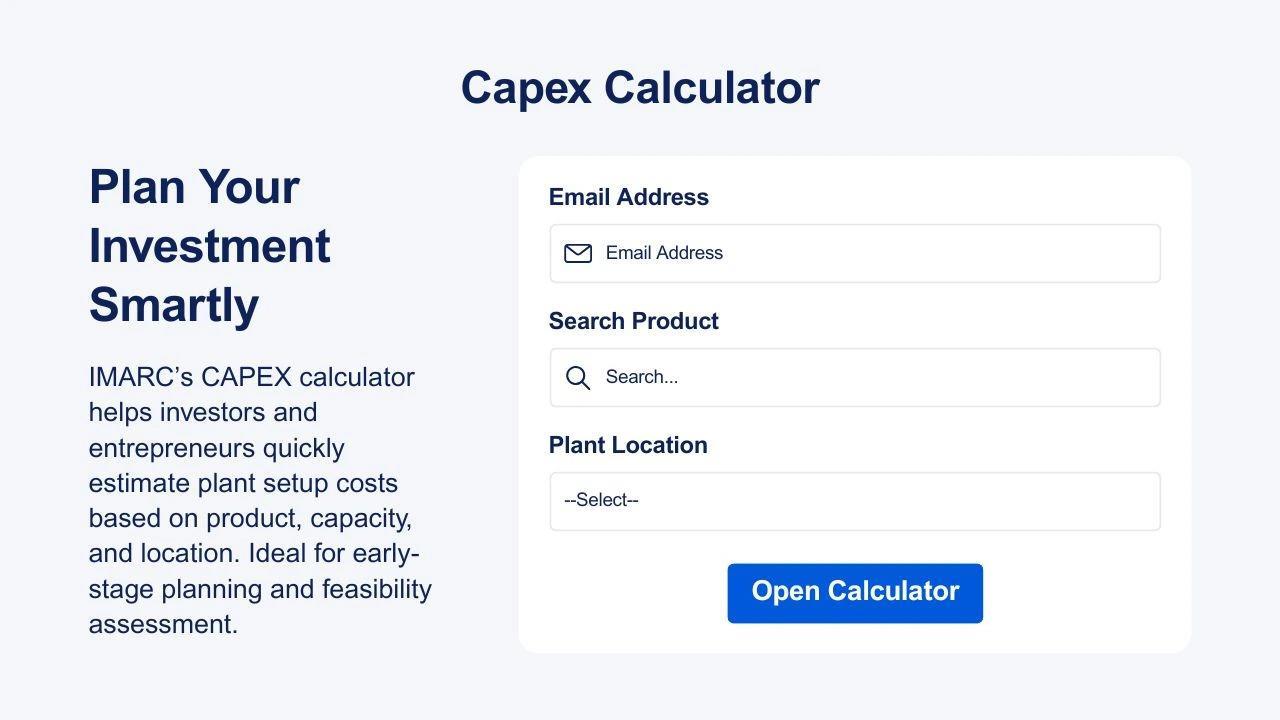

IMARC Group's report, titled “ Creatine Monohydrate Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue,” provides a complete roadmap for setting up a creatine monohydrate manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Request for a Sample Report : https://www.imarcgroup.com/creatine-monohydrate-manufacturing-plant-project-report/requestsample

Creatine Monohydrate Industry outlook 2025:

The creatine monohydrate industry in 2025 is expected to witness steady growth, driven by rising demand from the sports nutrition, bodybuilding, and fitness sectors. Increasing consumer awareness of muscle recovery, strength enhancement, and performance benefits is fueling market expansion, alongside growing adoption among recreational athletes. Technological advancements in production processes are improving product purity and cost efficiency, enhancing competitiveness. Asia-Pacific is anticipated to record the fastest growth due to a surge in fitness culture and expanding dietary supplement markets. However, market players must address regulatory compliance, raw material price fluctuations, and increasing competition from alternative performance-enhancing supplements to sustain profitability.

Key Insights for Creatine Monohydrate Manufacturing Plant Setup:

Detailed Process Flow:

-

Product Overview

Unit Operations Involved

Mass Balance and Raw Material Requirements

Quality Assurance Criteria

Technical Tests

Project Details, Requirements and Costs Involved:

-

Land, Location and Site Development

Plant Layout

Machinery Requirements and Costs

Raw Material Requirements and Costs

Packaging Requirements and Costs

Transportation Requirements and Costs

Utility Requirements and Costs

Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

-

Capital Investments

Operating Costs

Expenditure Projections

Revenue Projections

Taxation and Depreciation

Profit Projections

Financial Analysis

Profitability Analysis:

-

Total Income

Total Expenditure

Gross Profit

Gross Margin

Net Profit

Net Margin

Key Cost Components of Setting Up a Creatine Monohydrate Plant :

-

Raw Materials: Raw Materials: Procurement of sarcosine, cyanamide, catalysts, and other chemicals essential for synthesis.

Production Equipment: Investment in reactors, filtration units, drying systems, mixers, and packaging machinery.

Infrastructure & Facilities: Construction or leasing of manufacturing space, utilities setup, and storage areas.

Labor & Staffing: Salaries for skilled chemists, engineers, quality control staff, and operational workers.

Quality Control & Testing: Laboratory setup, analytical instruments, and routine product testing costs.

Regulatory Compliance: Licensing, certifications, GMP adherence, and environmental safety measures.

Energy & Utilities: Electricity, water, steam, and waste management expenses.

Packaging & Labeling: Containers, labeling materials, and branding-related costs.

Economic Trends Influencing Creatine Monohydrate Plant Setup Costs 2025 :

-

Raw Material Price Volatility: Fluctuations in sarcosine and cyanamide prices due to global supply chain pressures and chemical industry demand shifts.

Energy Cost Inflation: Rising electricity and fuel prices impacting production and drying processes.

Regulatory Tightening: Stricter GMP, food safety, and environmental compliance increasing setup and operational expenditures.

Technological Advancements: Adoption of more efficient production methods lowering long-term costs but requiring higher initial investment.

Labor Market Dynamics: Increased wages for skilled chemical engineers and quality specialists in competitive manufacturing hubs.

Currency Exchange Rates: Impacting import costs for equipment and raw materials in export-oriented regions.

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=16251&flag=E

Challenges and Considerations for Investors in Creatine Monohydrate Plant Projects:

-

Regulatory Compliance: Meeting stringent health, safety, and environmental standards across multiple jurisdictions.

Market Competition: Facing established global brands and low-cost regional producers.

Quality Assurance: Maintaining high purity and consistency to meet consumer and industry expectations.

Supply Chain Risks: Dependence on stable and cost-effective raw material availability.

Capital Intensity: High upfront investment in specialized equipment and infrastructure.

Technological Upgrades: Need for continuous improvement to remain competitive and efficient.

Market Demand Fluctuations: Sensitivity to trends in sports nutrition and fitness markets.

Conclusion:

The creatine monohydrate industry in 2025 presents significant growth potential, driven by expanding fitness trends, increasing sports supplement consumption, and technological advancements in manufacturing. Establishing a production facility offers promising returns but requires substantial capital investment, stringent regulatory compliance, and robust quality control measures. Investors must carefully evaluate raw material sourcing, operational efficiency, and market positioning to remain competitive in a landscape marked by price volatility and evolving consumer preferences. Strategic planning, adoption of advanced production technologies, and alignment with global quality standards will be critical for achieving long-term success in creatine monohydrate manufacturing ventures.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales[@]imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment