The Role Of Automation In Enhancing CNC Machine Efficiency Robotics & Automation News

In today's fast-changing manufacturing world, integration of automation with CNC has really enabled change in the sense of operational efficiency and precision.

This concept of integrated automation in CNC machining, mainly through advanced workholding solutions, forms the basis upon which industries today base their productivity intensification and competitiveness sustaining strategies.

The Essence of Automation in CNC OperationsAmong the implementations of automation in the manufacturing area, particularly within the CNC machine environment, are technologies that include robotics, software, and advanced sensory technologies.

Such innovations tend to determine the readiness for development of the operational capabilities of the CNC machines to be faster, more reliable, and more capable of producing minimal human intervention.

Enhanced Precision and Reduced WastePrecision is highly imperative in CNC machining since it determines the quality and usability of the final product.

Automation ensures that there is higher level accuracy, thus introducing less human error and preventing loose and erratic movement as a result of inconsistent pressure and placement of materials.

Check out our concepts on CNC Workholding Solutions as we discuss pneumatic mechanisms, which provide consistent and controlled pressure. Their most effective applications lie in scenarios requiring intricate detailing and high repeatability.

Automated workholding solutions ensure very precise operation hence reducing waste materials. This saves cost and is aligned with green manufacturing operations through eliminating the scrap.

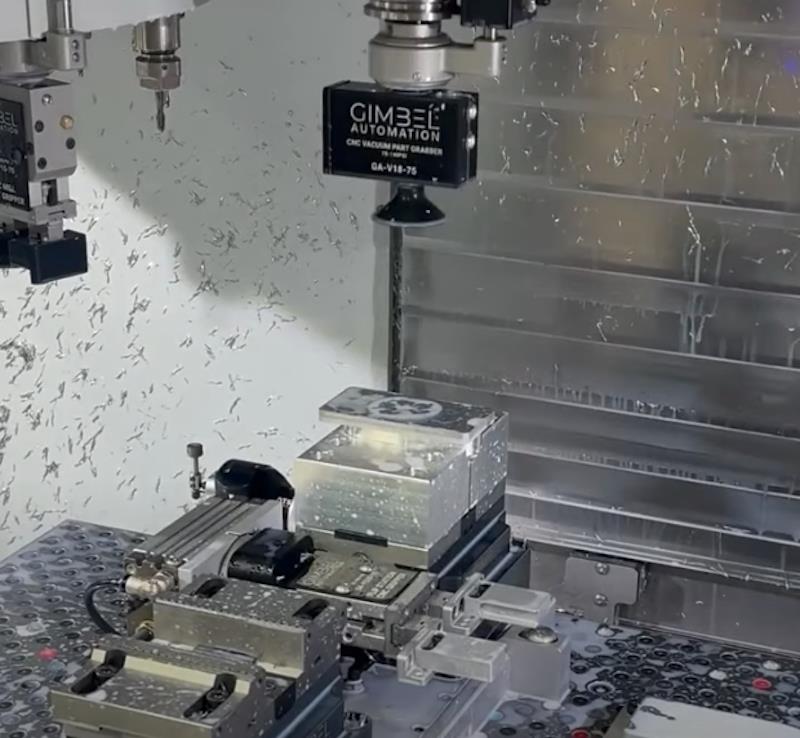

In order to see these technologies, watch this video from Gimbel Automation to observe the effect of automation in a CNC machining process.

Scalability and Flexibility in ProductionAutomated CNC workholding is of such a nature that the manufacturers can produce scaled operations without proportionate increases in labor cost.

These systems are versatile to handle more than one workpiece and have a fast turnaround time between production runs, making them invaluable in mass production situations.

Besides, with automated systems, flexibility is given so that adaptation to changes in new production requirements becomes very easy. Now, in industries, customers' specifications may change easily and quickly, and it's a big advantage of such systems.

Integration of CNC AutomationThe term CNC Automation is much larger than workholding and comprises the entire operational system of a machine.

Such a system includes complex software with predictive maintenance capabilities, real-time adjustment of operations, and in some cases, even simulates machining processes before the actual production process commences.

This, therefore, enhances overall operational efficacy.

Reducing Operational Costs and Enhancing OutputProcesses automation crucially renders labor-intensive features of CNC processes redundant, ensuring that only the skilled workforce is reserved for more significant functions, such as quality control and programming of machines.

Besides optimizing labor costs, output is increased through the allowance of round-the-clock production capabilities that do not require continuous human vigil.

Future Trends: IoT and AI in CNC MachiningAhead, integration of IoT and AI in the CNC machining process should see boundaries push forward from what automated systems can deliver. IoT devices can track real-time machine health, and AI can analyze that data to optimize machine performance and predict possible failures before they happen.

It is always through this predictive approach that continuous improvement in processes and minimization of downtime becomes possible.

ConclusionIt is incontestable how automation impacts the efficiency of CNC machines, thereby increasing precision, costs, and close people to sustainable practices.

With the help of automation, manufacturers are able to fulfill the changing needs of the market in an efficient and effective manner. Continuing innovations in this space point promisingly towards better operations for CNC machines.

Are you ready to revolutionize your CNC operations with leading-edge automation? Visit Gimbel Automation to discover how advanced pneumatic workholding can change everything for you regarding your production efficiency.

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment