Diphenyl Oxide Manufacturing Plant Report 2024: Investment Opportunities, Setup, Cost And Revenue

“ Diphenyl Oxide Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue ” provides a comprehensive guide for establishing an diphenyl oxide manufacturing plant. The report covers various aspects, ranging from a broad market overview to intricate details like unit operations, raw material and utility requirements, infrastructure necessities, machinery requirements, manpower needs, packaging, and transportation requirements, and more.

In addition to the operational aspects, the report also provides in-depth insights into diphenyl oxide manufacturing plant setup cost, process, project economics, encompassing vital aspects such as capital investments, project funding, operating expenses, income, and expenditure projections, fixed and variable costs, direct and indirect expenses, expected ROI, net present value (NPV), profit and loss account, and thorough financial analysis, among other crucial metrics. With this comprehensive roadmap, entrepreneurs and stakeholders can make informed decisions and venture into a successful diphenyl oxide manufacturing unit.

Customization Available:

- Plant Location Plant Capacity Machinery- Automatic/ Semi-automatic/ Manual List of Machinery Provider

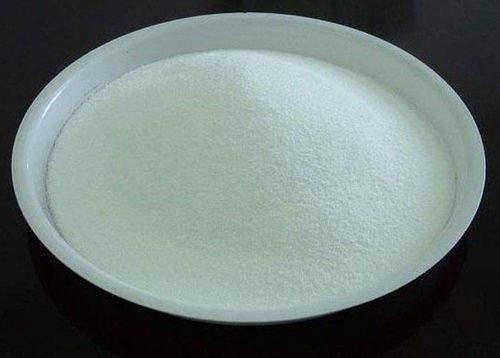

Diphenyl oxide, also known as diphenyl ether, is a versatile chemical compound with a wide range of applications across various industries. Its unique properties, including its high boiling point, chemical stability, and flame-retardant capabilities, make it invaluable in the production of heat transfer fluids, as a solvent in organic synthesis, and as a precursor in the manufacturing of fragrances and pharmaceuticals. In recent years, the demand for diphenyl oxide has been steadily increasing, driven by the growing automotive, electronics, and construction sectors. Moreover, stringent safety regulations and the emphasis on fire safety in buildings have further fueled the demand for flame-retardant materials, thereby driving the market for diphenyl oxide.

The market for diphenyl oxide is significantly influenced by several key drivers and trends, reflecting its diverse applications across industries. One primary driver is the increasing demand for flame retardants in various sectors, including electronics, textiles, and construction. As safety regulations become more stringent, the need for efficient flame-retardant materials has escalated, propelling the demand for diphenyl oxide as a crucial component in their synthesis. Moreover, the compound's role in the production of pharmaceuticals and fragrances contributes to its sustained market growth. Another notable trend is the rising emphasis on sustainable and eco-friendly solutions. Diphenyl oxide is increasingly sought after in the development of green flame retardants, aligning with global initiatives to reduce environmental impact. The compound's versatility as a building block in organic synthesis aligns with the growing trend of molecular customization in pharmaceuticals and specialty chemicals. Furthermore, ongoing research and development efforts to enhance the compound's properties and explore novel applications contribute to the dynamic nature of the diphenyl oxide market. As industries continue to prioritize safety, sustainability, and innovation, diphenyl oxide is poised to remain a pivotal player in diverse chemical and material applications.

Request For a Sample Report: https://www.imarcgroup.com/diphenyl-oxide-manufacturing-plant-project-report/requestsample

Key Insights Covered the Diphenyl Oxide Manufacturing Plant Report

Market Coverage:

- Market Trends Market Breakup by Segment Market Breakup by Region Price Analysis Impact of COVID-19 Market Forecast

Key Aspects Required for Setting Up a Diphenyl Oxide Manufacturing Plant

Detailed Process Flow:

- Product Overview Unit Operations Involved Mass Balance and Raw Material Requirements Quality Assurance Criteria Technical Tests

Project Details, Requirements and Costs Involved:

- Land, Location and Site Development Plant Layout Machinery Requirements and Costs Raw Material Requirements and Costs Packaging Requirements and Costs Transportation Requirements and Costs Utility Requirements and Costs Human Resource Requirements and Costs

Project Economics:

- Capital Investments Operating Costs Expenditure Projections Revenue Projections Taxation and Depreciation Profit Projections Financial Analysis

Key Questions Addressed in This Report:

- How has the diphenyl oxide market performed so far and how will it perform in the coming years? What is the market segmentation of the global diphenyl oxide market? What is the regional breakup of the global diphenyl oxide market? What are the price trends of various feedstocks in the diphenyl oxide industry? What is the structure of the diphenyl oxide industry and who are the key players? What are the various unit operations involved in a diphenyl oxide manufacturing plant? What is the total size of land required for setting up a diphenyl oxide manufacturing plant? What is the layout of a diphenyl oxide manufacturing plant? What are the machinery requirements for setting up a diphenyl oxide manufacturing plant? What are the raw material requirements for setting up a diphenyl oxide manufacturing plant? What are the packaging requirements for setting up a diphenyl oxide manufacturing plant? What are the transportation requirements for setting up a diphenyl oxide manufacturing plant? What are the utility requirements for setting up a diphenyl oxide manufacturing plant? What are the human resource requirements for setting up a diphenyl oxide manufacturing plant? What are the infrastructure costs for setting up a diphenyl oxide manufacturing plant? What are the capital costs for setting up a diphenyl oxide manufacturing plant? What are the operating costs for setting up a diphenyl oxide manufacturing plant? What should be the pricing mechanism of the final product? What will be the income and expenditures for a diphenyl oxide manufacturing plant? What is the time required to break even? What are the profit projections for setting up a diphenyl oxide manufacturing plant? What are the key success and risk factors in the diphenyl oxide industry? What are the key regulatory procedures and requirements for setting up a diphenyl oxide manufacturing plant? What are the key certifications required for setting up a diphenyl oxide manufacturing plant?

About Us

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC Group's information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company's expertise.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email:

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145 | United Kingdom: +44-753-713-2163

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Most popular stories

Market Research

- Daytrading Publishes New Study On The Dangers Of AI Tools Used By Traders

- New Silver Launches In California And Boston

- Digital Gold ($GOLD) Officially Launches On Solana, Hits $1.8M Market Cap On Day One

- Meme Coin Little Pepe Raises Above $24M In Presale With Over 39,000 Holders

- Bitmex And Tradingview Announce Trading Campaign, Offering 100,000 USDT In Rewards And More

- Your Bourse And B2BROKER Partner To Deliver Complete Brokerage Solutions

Comments

No comment