(MENAFN- Asia Times)

TOKYO – As the war in Ukraine drives oil and gas prices through the roof, reducing energy consumption has become an even higher priority. One important initiative in Japan is focused on power semiconductors.

Japan's New Energy and Industrial technology Development Organization – NEDO – is coordinating a project aimed at reducing the energy loss of power management devices by 50% while reducing the cost of mass-producing silicon carbide (SiC) power semiconductors to the same level as standard silicon-based chips by 2030. It also aims to develop more advanced gallium nitride (GaN) devices.

This should lead to cheaper and more efficient electric vehicles, renewable energy, factory automation, computers and telecom equipment, data centers, air conditioning, lighting, consumer electronics – and, we should not forget, aerospace and defense. The Japanese government will spend about 30.5 billion yen (US$260 million) on the project. The private companies involved are investing much more.

What is a power semiconductor?

As explained by Shindengen and Sanken, two Japanese companies that specialize in the field, power semiconductors supply and control electricity used to run motors, charge batteries and so on, by converting electric power from AC to DC and adjusting voltages to appropriate levels.

As pointed out by Toshiba in a recent press release, power semiconductors“are essential components for managing and reducing power consumption in every kind of electronic equipment, and for achieving a carbon-neutral society.”

What is silicon carbide?

Silicon carbide, as the words imply, is a compound consisting of silicon and carbon. Most semiconductors are made of silicon (hence Silicon Valley). Compared with silicon, silicon carbide semiconductors offer greater energy efficiency and reliability. Their advantages include resistance to higher voltages, tolerance of a wider range of temperatures and vibration and longer device lifetimes.

As noted by German power semiconductor maker Infineon on its website,“semiconductor materials such as gallium nitride (GaN) and silicon carbide (SiC) are the ideal choice when looking for the next generation of efficient power converter switches…. The key for the next essential step toward an energy-efficient world lies in the use of these … materials that allow for greater power efficiency, smaller size, lighter weight, lower overall cost – or all of these together.”

The unit cost of a SiC power semiconductor is still two to three times that of one made of silicon, but the functional gains are already driving rapid growth in demand. GaN is considerably more expensive and more difficult to work.

The NEDO Power Device Consortium includes three semiconductor makers and four makers of materials and equipment used in their production. The semiconductor makers involved in the project are Rohm, Toshiba and Denso.

Rohm is Japan's top producer of both SiC power semiconductors and, through its German subsidiary SiCrystal, the SiC wafers on which they are fabricated. It has been working on the technology for more than 20 years and now has more than 10% of the global market for SiC power semiconductors and has 15-20% of the market for SiC wafers, according to its own estimates.

Rohm recently opened a new factory in Japan that is large enough to increase its SiC power semiconductor production by five times over the next five years. In the NEDO project, Rohm will concentrate on industrial equipment.

The Electronic Devices division of Toshiba, one of Japan's large industrial conglomerates, makes power semiconductors for automotive, industrial and consumer applications. Toshiba will concentrate on trains, offshore wind power generators and data centers.

A logo of Toshiba Corp is seen on a printed circuit board. File photo: Agencies

According to Nikkei Asia (February 25, 2022), Toshiba plans to increase production of silicon carbide power semiconductors by more than three times by 2024 and 10 times by 2026. Toshiba does not take responsibility for these numbers, but a significant increase in capacity seems likely.

Denso, one of the world's top makers of auto parts, is affiliated with Toyota. It designs and fabricates power semiconductors, semiconductor sensors and integrated circuits (ICs) for engine electronic control units (ECUs) and other automotive applications.

In addition to battery-powered electric vehicles, Toyota plans to use silicon carbide power semiconductors in its Mirai hydrogen fuel cell vehicles.

Other Japanese companies that make power semiconductors but are not members of the consortium include Mitsubishi Electric, a leading manufacturer of factory automation, automotive and power generation equipment; Renesas, one of the world's top makers of automotive semiconductors; Fuji Electric, which makes electric power and industrial components and equipment; and the above-mentioned Shindengen and Sanken.

The materials and equipment makers in the consortium are working on the development of low-cost SiC wafers and semiconductors, and their use in electric vehicles and other“next-generation green power” applications. They are Showa Denko, Central Glass, Mipox and Oxide.

Showa Denko makes SiC wafers and also supplies the semiconductor industry with high-purity gases and chemicals. Central Glass, Japan's third-largest glass maker, supplies glass and fine chemical products to the semiconductor industry.

Mipox makes nano-level ultra-fine particle slurry for use in the polishing of SiC and other compound semiconductors. Oxide possesses crystal growing, micro-machining, module fabrication and measurement technologies.

In addition to providing a description of what's going on, the point of listing up all these companies (and more below) is to demonstrate the complexity of the power semiconductor supply chain. There is a lot more to the semiconductor industry than it might seem from all the attention paid to Huawei, TSMC and Intel.

Led by Rohm, Japanese companies now have roughly 20% of the SiC power semiconductor market. The NEDO project targets 40% by 2030. It won't be an easy goal to reach.

The largest companies in the industry are Wolfspeed (formerly Cree) of the United States, which has more than 60% of the market for SiC wafers; Infineon of Germany, which appears to have more than 30% of the market for SiC power semiconductors, STMicroelectronics, a French-Italian company headquartered in Switzerland; and onsemi (ON Semiconductor) of the US.

Like the Japanese, all of them are expanding production and making significant investments to improve the technology. Aggressive investment in new capacity can lead to big changes in market share. When Rohm began mass production of SiC power semiconductors in 2010, its market share was effectively zero.

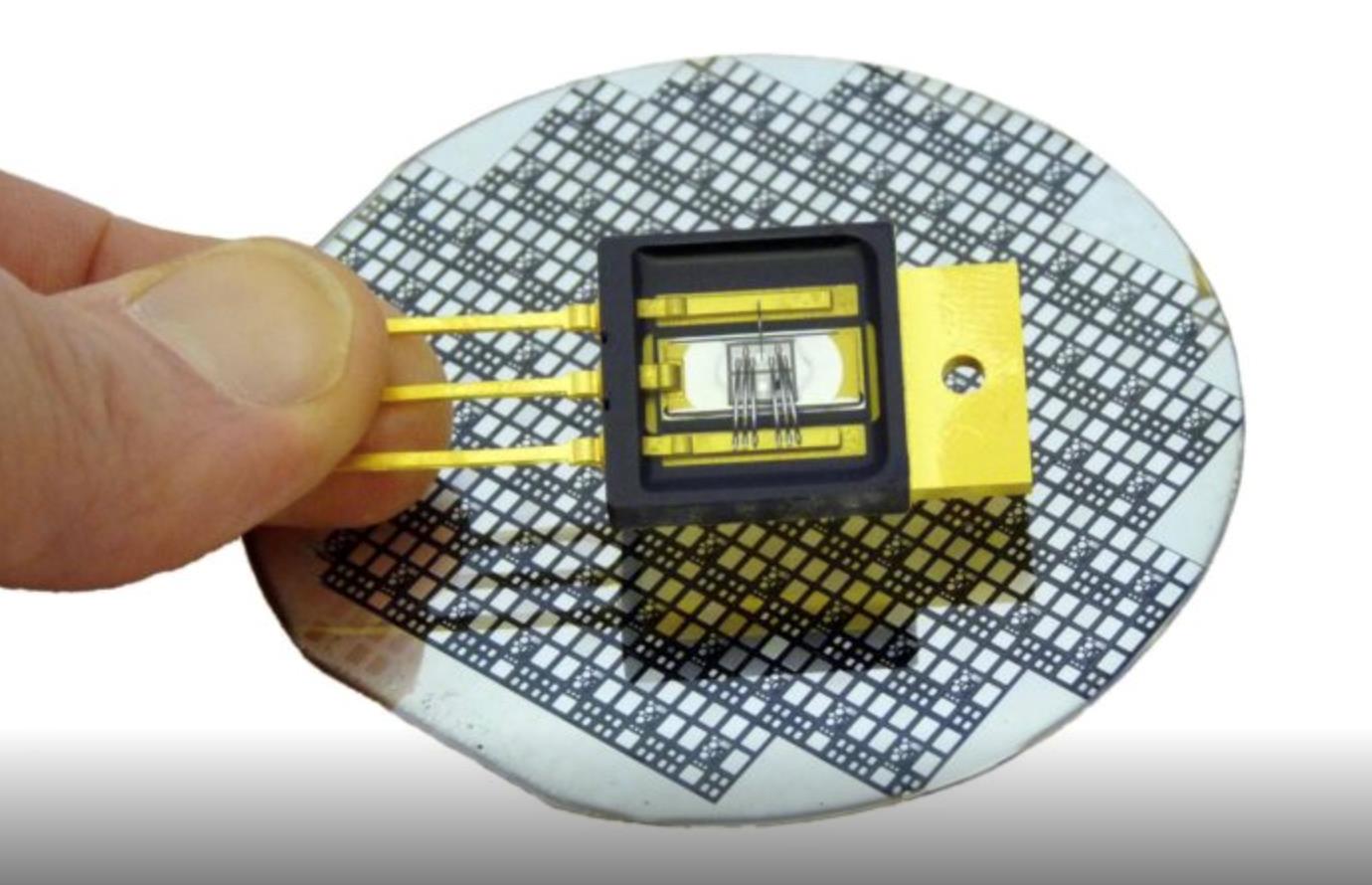

SIC chips are expensive to make but efficient. Image: Facebook

Chinese semiconductor makers, supported by national industrial policies aimed at reducing power consumption and carbon emissions, are also developing their capabilities in silicon carbide power semiconductors. Three prominent examples are HHGrace, WeEn and CanSemi.

HHGrace (Shanghai Huahong Grace Semiconductor Manufacturing Corp.) produces power semiconductors and other products for automotive, industrial, lighting and other applications.

WeEn Semiconductors is a joint venture company founded by NXP Semiconductor of the Netherlands and Beijing JianGuang Asset Management. Headquartered in Shanghai, it has factories in China, R&D centers in China and Britain, more than 5,000 customers worldwide and a German CEO. It specializes in power semiconductors and other products derived from NXP.

CanSemi (Guangzhou CanSemi Technology Inc.) is a semiconductor contract manufacturer (foundry) that makers power semiconductors for applications including the Internet of Things, automotive electronics, industrial control and telecommunications.

China is also producing silicon carbide for use as power semiconductor substrates. This is key to eliminating dependence on foreign supplies that might be targeted by American sanctions.

Last June, the Chinese press reported that the launch ceremony of China's firs silicon carbide vertically integrated industrial chain took place in Changsha High-tech Industrial Park in Central China's Hunan Province.“The Hunan San'an Semiconductor Base is capable of producing 30,000 6-inch silicon carbide wafers per month once put into mass production,” reported Global Times.

Not“is producing,” not yet anyway. Rather, it will be, if all goes according to plan.

The article goes on to note that SiC power semiconductors can be used in numerous applications supported by China's industrial policy. These include telecommunications equipment (including 5G), server power supplies (data centers), solar power and other clean energy systems, smart power grids, electric vehicles and railways.

Other Chinese producers of silicon carbide include GZSC (Guangzhou Summit Crystal), which produces single-crystal silicon carbide materials, and TankeBlue Semiconductor, which makes silicon carbide wafers. Both are state-controlled.

That having been said, industry research and news site SemiAnalysis reports that“China has built the world's most expensive silicon carbide fab, but the numbers don't add up.”

Hunan Sanan, it says,“aims to be a fully integrated SiC wafer fab from boule growth and slicing all the way to power devices, packaging, and testing.” In the semiconductor industry a“boule” is produced by dipping a seed crystal into pure molten silicon and then slowly extracting a long cylindrical ingot with a diameter sufficient to make silicon wafers.

“This facility has an eye-popping $2.5 billion price tag for phase 1 and 2 with a total output of 30,000 6” wafers per month. Sanan Optoelectronics, the parent company, has stated the phase 1 was built in less than a year and can already produce 6” SiC wafers.”

However,“Even if we believe Sanan has figured out the incredibly difficult process of boule crystal growth, slicing, polishing, cleaning, doping, epitaxial growth, ion implantation, device manufacturing, and the entire test cycle, the total wafer counts make no sense.”

SemiAnaysis asks,“Is this another case where government initiatives, subsidies, and unrealistic targets end up in lighting money on fire?”

A silcon carbide chip wafer. Image: GE / Website

Maybe. China has a long record of failed semiconductor industry projects. But, like South Korea, it also has a record of never giving up, of trying and trying again until it succeeds, regardless of whether or not that makes sense from a Western or Wall Street point of view.

If I had to, I would bet that China will be a significant producer of silicon carbide wafers and semiconductor devices by the end of this decade, with market shares of perhaps 10%. Unless America tries to sabotage it, in which case it might become self-sufficient much more rapidly.

South Korea and Taiwan are also likely to establish a meaningful presence in the industry.

French market research and consulting firm Yole Developpement has forecast global demand for SiC power semiconductors to increase by about four times to $4.5 billion by 2026. Driven by demand for greater energy efficiency and lower carbon emissions – and by competition within and between countries – it should keep right on growing after that.

Scott Foster is an analyst with LightStream Research, Tokyo. Follow him on Twitter @ScottFo83517667.

MENAFN13032022000159011032ID1103834820