Decolorization Method Developed By University Of Fukui Researchers Heralds A Structural Reform In The Textile Industry

FUKUI, Japan, Oct. 23, 2024 /PRNewswire/ -- In the apparel industry, approximately 60% of textile products are discarded without ever being purchased. Mass disposal of textiles has a grave impact on the environment, making the textile industry the world's second most environmentally damaging industry due to heavy usage of toxic chemicals during dyeing, processing, and finishing. This calls for urgently adopting sustainable practices to reduce the environmental burden of textile waste.

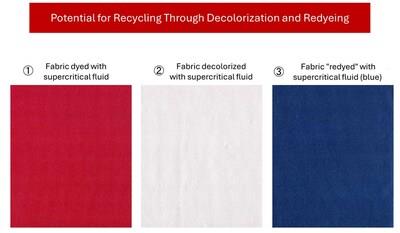

Decolorizing and reusing textiles, specifically polyester fibers, which dominate the textile market, can be a way forward.

Decolorization and redyeing of fabrics using supercritical fluids

Researchers from University of Fukui, Japan have optimized a decolorization process, known as supercritical fluid dyeing, in which supercritical carbon dioxide effectively penetrates fabric fibers to remove the dyes. The extracted dyes can be reused, and the fabrics be redyed. The study was led by Professor Kazumasa Hirogaki and Visiting Professor Teruo Hori and achieved successful optimization of the decolorization process, enabling the dye removal from clothes with minimal environmental impact. This study builds on outcomes from the NEDO Feasibility Study Program/Feasibility Study Program on New Technology and was further developed under the JST COI-NEXT Program on open innovation platforms for industry-academia co-creation (COI-NEXT).

The researchers first created supercritical carbon dioxide (CO2) fluid inside a specialized heated and pressurized vessel and mixed it with a decolorizing agent before adding it to the dyed fabric. The idea was that by adding a decolorizing agent with a solubility parameter between those of the dye and the fabric, efficient decolorization could be achieved. Based on this premise, three decolorization methods can be outlined- to be used depending on the characteristics of the textile, the dyes, and the decolorizing agent.

The first method is called solvent trapping, in which supercritical CO2 dissolves and then traps the dye in a solvent phase at the bottom of the vessel. In contrast, the solid trapping method involves re-treating a processing body with a decolorizing agent or placing an adsorbent in the vessel. The supercritical fluid extracts the dye and then traps it onto the processing body or adsorbent. Finally, in the homogenous method, the decolorizing agent is completely dissolved in the supercritical fluid and the extracted dye also dissolves in the supercritical fluid.

Using these techniques, an astounding decolorization rate of over 90-100% was achieved. Notably, this strategy was found to be effective for polyester fabrics. Moreover, the processing liquids, extracted dyes, and decolorizing agents can also be repurposed and reused effectively.

Owing to its tremendous potential in terms of sustainability, the team of researchers from University of Fukui is actively seeking to commercialize this technology, with hopes of transforming the "make, use, and dispose" model of the textile industry into a truly circular and sustainable "make, use, and reuse" model.

Here's wishing them luck in their endeavor to mitigate the environmental impact of textiles!

The original news is published here:

Reference:

Research project name:

NEDO Feasibility Study Program / Feasibility Study Program on New Technology

JST COI-NEXT Program on open innovation platforms for industry-academia co-creation (COI-NEXT).

Researchers name: Professor Kazumasa Hirogaki,

Visiting Professor and President of SUSTAINA TECH Co., Ltd. Teruo Hori.

Affiliation: University of Fukui

Link to research project summary page:

Contact:

Mika Hayashi

+81 776-27-9931

[email protected]

SOURCE University of Fukui

WANT YOUR COMPANY'S NEWS FEATURED ON PRNEWSWIRE? 440k+Newsrooms &

Influencers 9k+

Digital Media

Outlets 270k+

Journalists

Opted In GET STARTED

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Most popular stories

Market Research

- New Cryptocurrency Mutuum Finance (MUTM) Raises $15.8M As Phase 6 Reaches 40%

- Bydfi Joins Korea Blockchain Week 2025 (KBW2025): Deepening Web3 Engagement

- Yield Basis Nears Mainnet Launch As Curve DAO Votes On Crvusd Proposal

- 0G Labs Launches Aristotle Mainnet With Largest Day-One Ecosystem For Decentralized AI

- Ethereum-Based Defi Crypto Mutuum Finance (MUTM) Raises Over $16 Million With More Than 720M Tokens Sold

- Fintech's Gender Gap In Focus: Drofa Comms' Women Leading The Way Joins Evolvh3r's She Connects At TOKEN2049

Comments

No comment