(MENAFN- Newsfile Corp)

Vancouver, British Columbia--(Newsfile Corp. - October 31, 2024) - American Pacific mining Corp. (CSE: USGD) (OTCQX: USGDF) (FSE: 1QC) (" American Pacific " or "the Company ") is pleased to report assay results from the first seven (7) holes of the Company's sixteen (16) hole drill program at its Palmer Copper-Zinc VMS Project (" Palmer ") in Southeast Alaska. The 2024 drill program was part of a planned CAD $17.5 million (USD $12.8 million) exploration and development budget funded by a joint venture partnership between Dowa Metals & Mining Alaska Ltd. (" Dowa ") and American Pacific (see March 25, 2024 news release). The initial assay results provided herein are from South Wall Zone 1 and RW Zone (2 holes) of the Palmer Deposit.

Highlights include :

CMR24-194: 16.4 m of 0.8% Cu, 8.4% Zn, 0.6% Pb, 0.72 g/t Au and 77.5 g/t Ag (5.1 CuEq) ;

including 10.4 m of 1.17% Cu, 12.17% Zn, 1.01 g/t Au and 101.49 g/t Ag (7.3% CuEq) CMR24-193: 3.5 m of 0.1% Cu, 1.7% Zn, 0.6% Pb, 0.86 g/t Au and 92.4 g/t Ag (1.9% CuEq) CMR24-192: 2.9 m of 3.5% Cu, 0.68% Zn, 0.3 g/t Ag (3.8% CuEq) and 9.8 m of 0.58% Cu further downhole

Notes: m = metres; Cu=copper; Zn=zinc; Au=gold; Ag=silver; Pb=lead. CuEq=copper equivalent. Copper Equivalent calculated using the same metal prices and recovery assumptions as the Company's NI 43-101 Technical Report (JDS 2022). See Table 1 for all new assay results and corresponding disclosure notes.

"This year's drill program was successful in following up on last year's high-grade results, while better defining the known mineralization on the property, ahead of the updated Mineral Resource Estimate and Technical Report budgeted to begin this year," commented Peter Mercer, VP Advanced Projects for American Pacific. "The Palmer Project is located within a prolific mineral belt in Southeast Alaska. This mineral terrane extends hundreds of kilometres north and south of Palmer, hosting several historic and current mining operations. The Palmer and AG deposits are just two of the mineralized areas defined and drill tested to date, on the property that has district-scale potential."

The 2024 drill program included a total of 6,035.9 metres (19,650 feet) in nineteen (19) drill holes including three (3) drill holes (125.8 metres; 410 feet) that were recollared. The drill program was designed to continue infill drilling and testing the extents of the high-grade copper-zinc mineralization of the South Wall Zone 1 and Zone 2-3. The program also included three exploration drill holes for 1,033.3 metres (3,390 feet) to test the nearby North Wall Target testing, a potential fault offset extension of the South Wall mineralization.

Initial Observations and Interpretations

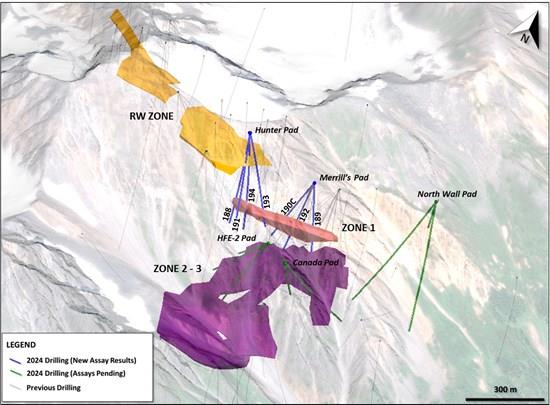

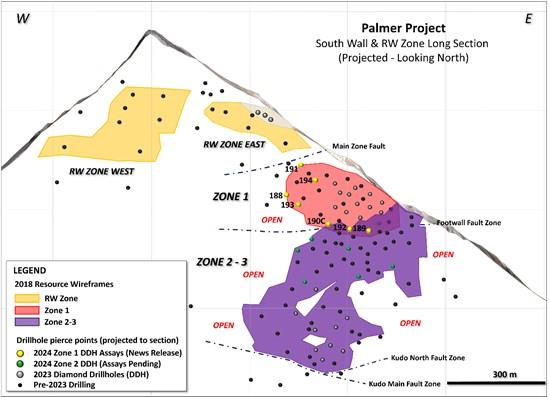

Highlights of the Zone 1 drilling indicate a high-grade zoning in the upper portion of Zone 1, with continuity of the mineralized horizon to the west and downdip. Drill hole locations are shown on Figure 1 and 2 with assay results provided on Table 1.

CMR24-194 infilled a 70-metre gap in the west portion of Zone 1 with a well mineralized interval over a drilled thickness of 16.4 metres (13.9 metres estimated true width). The mineralized interval intersected semi-massive to massive sulphides with barite over most of its length with significant copper, zinc, gold and silver grades. The infill drill hole reflects good continuity of the grade and thickness within the mineralized envelope.

CMR24-189, CMR24-191 and CMR24-193 tested and confirmed the western extension of Zone 1 mineralization with low-grade base and precious metal mineralization intersected along the projected mineralized horizon. Two of the drill holes (CMR24-191 and 193) intersected the RW Zone near the top of the drill holes with significant gold and silver mineralization, plus barite, intersected in CMR24-193. CMR24-189, CMR24-190C and CMR24-192 tested the downdip extension of Zone 1 and intersected significant zones of semi-massive to massive pyrrhotite and pyrite mineralization extending mineralization downdip. Assay results returned a large low-grade halo of base and precious metal mineralization with local higher-grade samples.

Figure 1: Isometric Plan view with 2024 drill holes - Palmer Deposit

To view an enhanced version of this graphic, please visit:

Figure 2: Projected Long Section - Palmer Deposit

To view an enhanced version of this graphic, please visit:

Photo 1: Piece of CMR24-189 split drill core from 247.8 to 248.0 m

To view an enhanced version of this graphic, please visit:

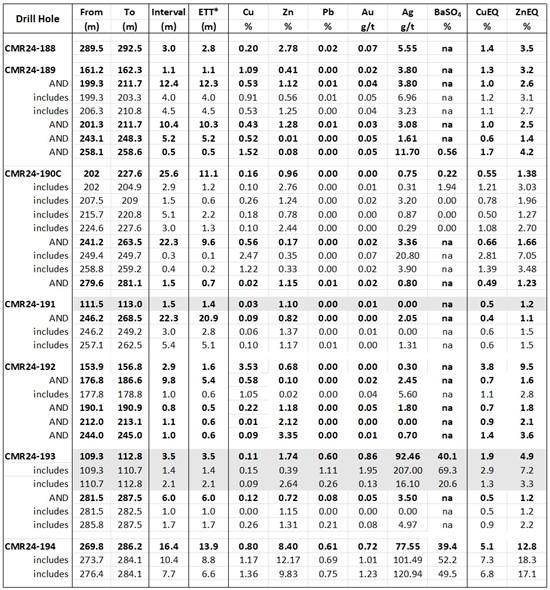

Table 1: Assay Results from Zone 1

To view an enhanced version of this graphic, please visit:

*ETT = Estimated True Thickness; na = samples not analyzed by XRF; BaSO4 not included in CuEQ or ZnEQ; Shaded areas in the table reflect the RW Zone.

Copper and Zinc Equivalent Notes:

ZnEQ = (Cu/100*2204.6*$lbCu*CuREC) + (Zn/100*2204.6*$lbZn*ZnREC) + (Au/31.1035*$ozAu*AuREC) + (Ag/31.1035*$ozAg*AgREC) / (2204.6/100*$lb Zn*ZnREC)

CuEQ = (Cu/100*2204.6*$lbCu*CuREC) + (Zn/100*2204.6*$lbZn*ZnREC) + (Au/31.1035*$ozAu*AuREC) + (Ag/31.1035*$ozAg*AgREC) / (2204.6/100*$lb Cu*CuREC)

Lead (Pb) and Barite (BaSO4) are not included in the CuEQ and ZnEQ values.

Assumed metal prices are US$1.15/lb for zinc (Zn), US$3.00/lb for copper (Cu), US$1250/oz for gold (Au), US$16/oz for silver (Ag) (JDS 2022).

Estimated metal recoveries (REC) are 93.1% for zinc, 89.6% for copper, 90.9% for silver and 69.6% for gold as determined from metallurgical locked cycle flotation tests completed in 2018 (JDS 2022).

Quality Assurance (QA) and Quality Control (QC)

There are strict Quality Assurance and Quality Control (QA/QC) protocols at Palmer covering the planning and placing of drill holes in the field; drilling and retrieving drill core; drill hole surveying; core transport to the Palmer Camp; core logging, sampling and bagging of core for analysis; transport of core samples from site to ALS Laboratory in North Vancouver, BC for sample preparation and analysis; recording and final statistical vetting of results.

Sampling Procedures - The Company's QA/QC drill core sample protocol consists of collection of samples over a minimum 0.3 m interval to a maximum 1.5 m interval (depending on the lithology and style of mineralization) over the mineralized portions of the drillhole. The drill core sample is cut in half with a diamond saw, with half of the core placed in individual sealed polyurethane bags and the remaining half securely retained in the original core box for permanent storage. Drill core samples are shipped by transport truck in sealed woven plastic bags to ALS Geochemistry Analytical Lab facility in North Vancouver, BC for sample preparation and analysis. ALS Geochemistry meets all requirements of International Standards ISO/IEC 17025:2017 and ISO 9001:2015. ALS Global operates according to the guidelines set out in ISO/IEC Guide 25.

Various metals including copper, lead, zinc and silver were analyzed by inductively coupled plasma (ICP) atomic emission spectroscopy, following multi-acid digestion. The elements copper, lead and zinc are determined by ore grade assay for samples that return values >10,000 ppm by ICP analysis. Silver is determined by ore-grade assay for samples that return >100 ppm by ICP analysis. Gold was determined by fire-assay fusion of a 30 g sub-sample with atomic absorption spectroscopy (AAS). Barium (BaO) analysis utilized lithium borate fusion into fused discs for XRF analyses, with BaO converted to BaSO4 (barite) using a conversion factor of BaO x 1.52217. Density measurements were determined at the project site by Constantine personnel on cut core for each assay sample.

The Company maintains a robust QA/QC program that includes the collection and analysis of duplicate samples and the insertion of blanks and standards (certified reference material). In addition, prepared samples, sample replicates, duplicates and internal reference materials are routinely used as part of ALS Geochemistry's internal quality assurance program.

Qualified Person Statement

The technical information in this news release regarding the Palmer Project has been reviewed and approved by Michael Vande Guchte, P.Geo., Vice President of Exploration for the Palmer Project and a Qualified Person (QP) as defined by National Instrument 43-101, Standards of Disclosure for Mineral Projects.

About American Pacific Mining Corp.

American Pacific Mining Corp. is a precious and base metals explorer and developer focused on opportunities in the Western United States. The Company has two flagship assets: the Palmer Project, a Volcanic Massive Sulphide-Sulphate (VMS) project in Alaska, under joint-venture partnership with Dowa Metals & Mining, owner of Japan's largest zinc smelter; and the Madison Project, a past-producing copper-gold project in Montana. For the Madison transaction, American Pacific was selected as a finalist in both 2021 and 2022 for 'Deal of the Year' at the S&P Global Platts Metals Awards, an annual program that recognizes exemplary accomplishments in 16 performance categories.

Also, in American Pacific's asset portfolio are high-grade, precious metals projects located in key mining districts in Nevada, USA, including the Ziggurat Gold Project and the Tuscarora Gold-Silver District. The Company's mission is to grow by the drill bit, strategic partnerships, and M&A.

MENAFN31102024004218003983ID1108837401

Legal Disclaimer:

MENAFN provides the information “as is” without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the provider above.