Fusion Diary: The Magnet Wizards

part 1 ,

part 2 ,

part 3 ,

part 4 ,

Part 5 ,

Part 6 and Part 7 .

In colloquial language, one might say,“When it comes to tokamaks, its all about magnets.” That is not literally true, but certainly the design and performance of a tokamak reactor are inseparably connected with those of its magnet system.

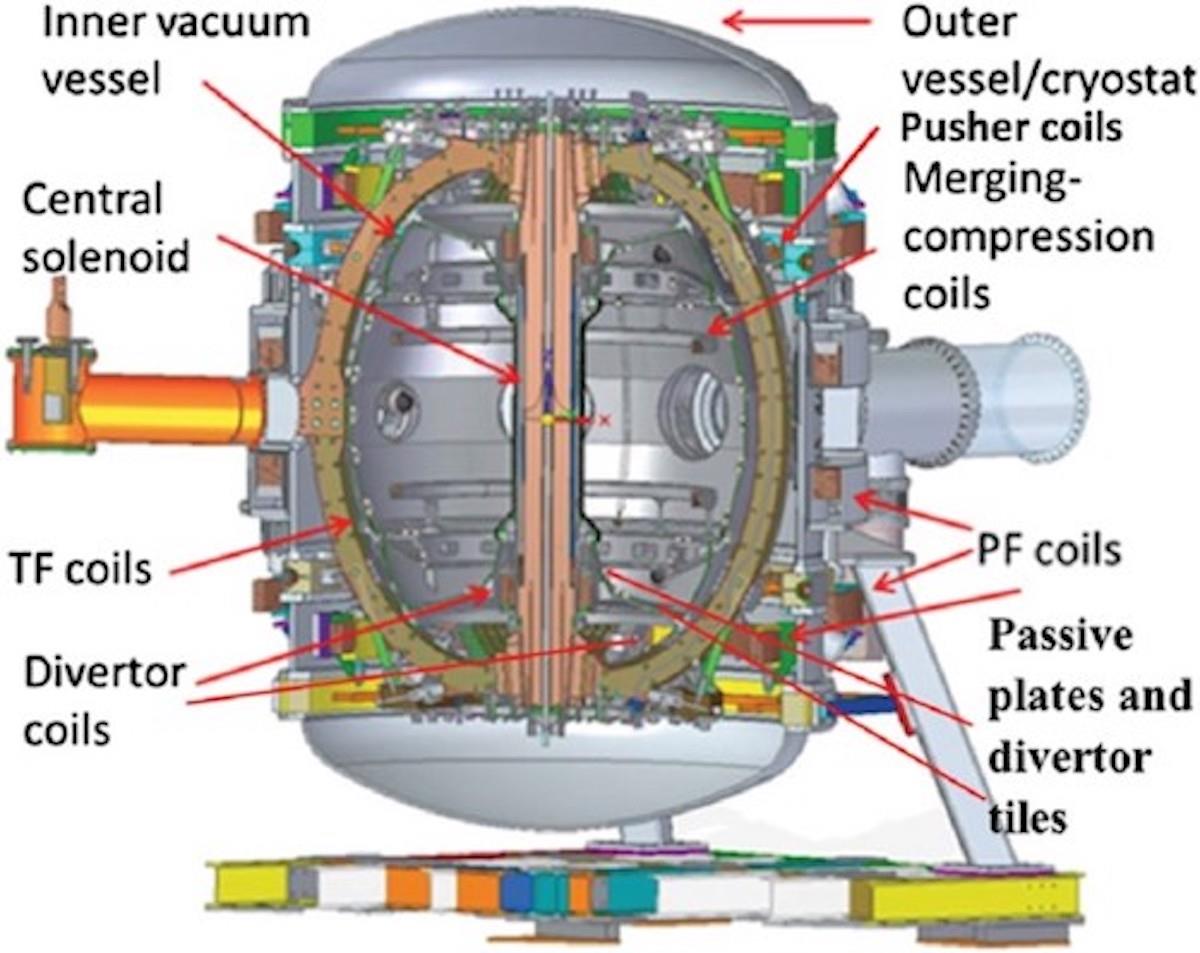

A tokamak utilizes a multitude of magnetic field-generating coils: toroidal coils and poloidal coils to contain and control the plasma, and a central solenoid that induces the required electrical current in the plasma.

Cutaway diagram of Tokamak Energy's ST40 reactor showing its system of magnet coils: toroidal (TF) coils, poloidal (PF) coils, divertor coils, central solenoid coil and coils for the 'merging compression' heating method. Image: Tokamak Energy Ltd

Improvements in magnet technology have been a major driver of progress in tokamak reactor performance. Alongside greatly improved computer modeling techniques, the development of powerful magnets utilizing high-temperature superconductors (HTS) provided one of the main grounds for optimism that the goal of economically viable fusion power is now within reach.

Among other things, HTS magnet technology makes it possible to achieve extremely high magnetic fields in a compact device, greatly reducing the size and cost of a fusion reactor.

Another private fusion company, Commonwealth Fusion Systems (CFS) also follows the pathway of compact high-magnetic-field tokamaks, but with the important difference, that Commonwealth's devices are based on the classical toroidal design, as opposed to the spherical tokamak design

pursued by Tokamak Energy Ltd and the UK government's STEP program.

The technology of high-temperature superconducting magnets has progressed rapidly over the last 10 years, marked by ever-higher magnetic field strengths. To be usable in a fusion reactor, however, HTS magnets must be able to operate reliably for long periods under extreme conditions, including intense neutron and gamma radiation, as well as large mechanical stresses.

Developing HTS magnets that can meet the requirements of future fusion power plants is a central focus of Tokamak Energy's efforts. The company is a leading international player in this area.

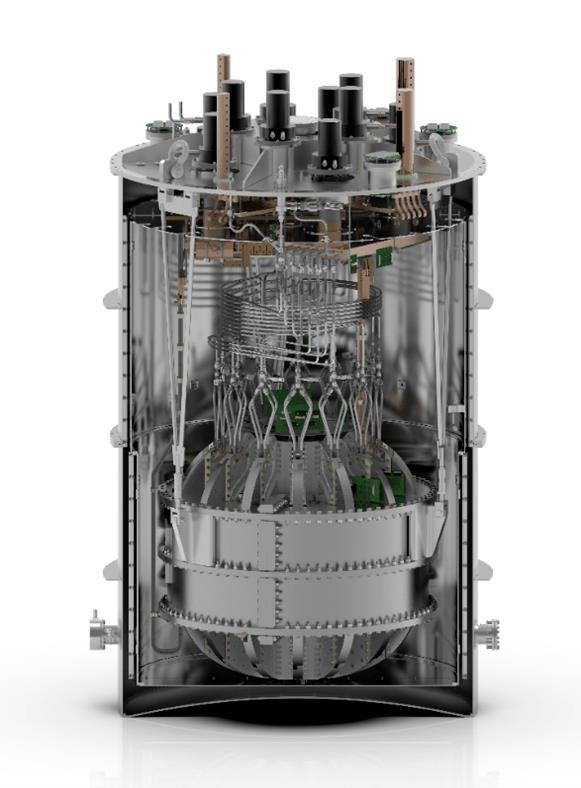

Tokamak Energy magnet experts with superconducting coils for the company's 'Demo4' device

Photo: Tokamak Energy Ltd

During my visit to the Tokamak Energy's Milton Park facility in Oxford, I had the opportunity to see the company's HTS magnet laboratory and to talk with one of its specialists, . He explained to me the challenges of developing compact, high-field HTS magnets for fusion reactors, and some of the company's ground-breaking innovations.

Tokamak Energy's magnet coils are wound from tape made from the high-temperature superconducting material REBCO (rare earth barium copper oxide). REBCO is superconducting at temperatures below about -180° C, as long as the current is not too high. To be able to carry large currents with zero resistance, REBCO must be cooled down even further.

The REBCO-based magnets in Tokamak Energy's next spherical tokamak reactor are designed to operate at about -25C. That doesn't sound like a“high temperature” – but it is significantly higher than the -270°C required for ordinary superconducting magnets and it requires five times less cooling power.

REBCO in bulk is a brittle material, and large-scale applications first became possible thanks to the development of flexible tapes containing thin layers of REBCO. and the per-kilometer price has decreased more than 10-fold.

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment