403

Sorry!!

Error! We're sorry, but the page you were looking for doesn't exist.

Al Gharbia Pipe Company's Reinforces Status As Industry 4.0 Technology Leader In LSAW Pipe Manufacturing

(MENAFN- Mid-East Info)

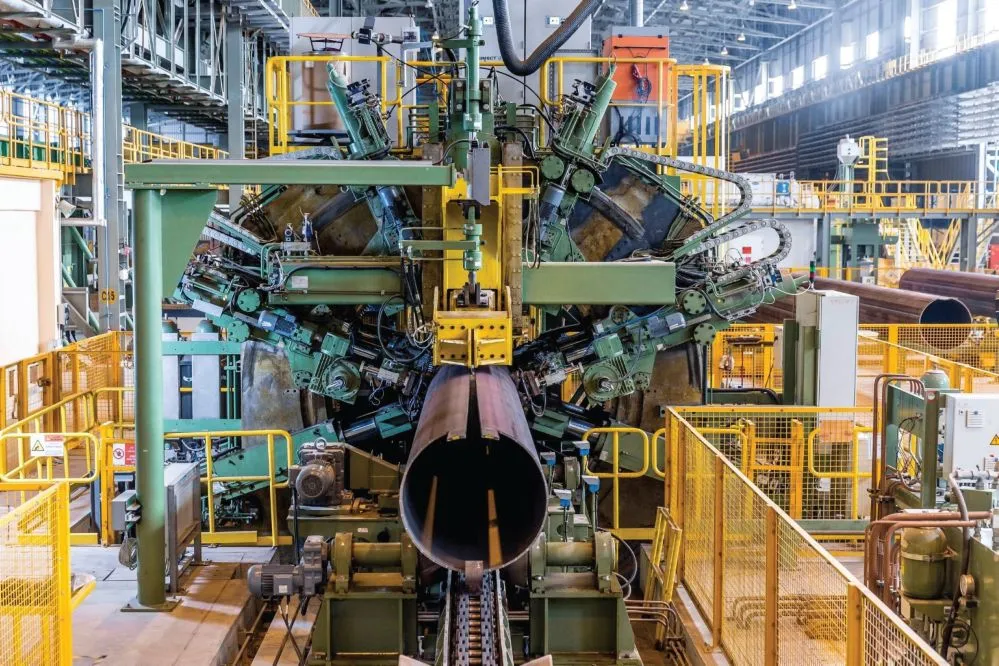

Abu Dhabi, UAE (3 November 2025) – Al Gharbia Pipe Company (AGPC), an Abu Dhabi-based producer of longitudinally submerged arc welded (LSAW) steel pipes, has received recognition from the UAE's Ministry of Industry & Advanced Technology (MoIAT) as an Industry 4.0 Digital Leader. This latest certification demonstrates AGPC's commitment to quality and its focus on continuous improvement of its manufacturing processes. Furthermore, this reinforces its place at the forefront of LSAW pipe manufacturing technology in the Middle East. “The Industry 4.0 Digital Leader certification is an important milestone for AGPC, as we harness technology and make significant contributions to the UAE's manufacturing sector,” said Noritsugu Mifune, CEO of Al Gharbia Pipe Company.“This certification confirms AGPC's leadership in digital transformation and positions us as a top performer within the LSAW steel pipe sector. This was made possible by the innovation, dedication, and teamwork of every member of our organisation, and we will continue to strengthen the UAE's industrialisation efforts as the leading and most technologically advanced LSAW pipe manufacturer in the region.” The Industry 4.0 Digital Leader certification is given by MoIAT to companies that demonstrate advanced digital maturity and leadership in adopting Industry 4.0 technologies, such as AI and machine learning. It signifies that a company is a leader in leveraging state-of-the-art technologies in the areas of operational efficiency, sustainable growth, and industrial competitiveness. This recognition and certification is part of the UAE's National Strategy for Industry and Advanced Technology, also known as Operation 300 Billion. The strategy aims to increase the industrial sector's contribution to national GDP to AED 300 billion by 2031 by transforming the UAE into a global industrial hub. As part of the certification process, AGPC underwent an Industrial Technology Transformation Index (ITTI) assessment. Such assessment is designed to improve industry competitiveness through technology adoption, enable evidence-based policymaking, accelerate innovation in manufacturing, and promote sustainability and efficient resource management. Ramesh Chandra Pathak, General Manager – Operations & Innovations, together with the Innovation Team, played a pivotal role in steering AGPC through the assessment and leading the digital transformation initiatives that resulted in the company's successful certification, officially awarded on 20 September 2025. The assessment noted AGPC's strong adoption of Industry 4.0 technologies. A key feature of its this is that all of AGPC's plant processes are connected through its smart Manufacturing Execution System (MES) 4.0, which executes, monitors, tracks and reports operations on the plant floor in real-time. MES acts as the brain connecting manufacturing and testing processes, as well as adapting production plans and schedules according to real-time conditions on the shop floor. In addition, its ISO/IEC 17025-certified testing laboratory ensures that each pipe conforms to stringent quality standards across all stages of the manufacturing process. AGPC was commended for having a fully integrated production process, encompassing production execution, utilities, sourcing, and sales processes. Furthermore, the company's efforts to improve sustainability, such as establishing emissions reduction and water reuse, were recognised. Since commencing production in 2019, AGPC has continually ramped up its production and quality control capabilities by adopting advanced technologies. Today, its factory can produce up to 360,000 metric tons, or an equivalent of 760 kilometres of pipeline, each year. It uses computer vision technology to detect micro-defects that may escape traditional methods. Through machine learning, these systems continuously learn and improve, ensuring that every pipe meets the highest standards of safety and durability, AGPC is certified to ISO, API, and international standards, and each pipe is custom-engineered to project specifications, including carbon steel pipes up to API X80 grade. Its pipes are used by major oil and gas, industrial, and renewable energy companies in the Middle East and beyond.

-

UAE's Ministry of Industry & Advanced Technology (MoIAT) certifies AGPC as Industry 4.0 Digital Leader

-

Recognition reflects AGPC's focus on strengthening its manufacturing processes and quality control through technology

Assessment highlights company's strong adoption of advanced technology and sustainability efforts

Abu Dhabi, UAE (3 November 2025) – Al Gharbia Pipe Company (AGPC), an Abu Dhabi-based producer of longitudinally submerged arc welded (LSAW) steel pipes, has received recognition from the UAE's Ministry of Industry & Advanced Technology (MoIAT) as an Industry 4.0 Digital Leader. This latest certification demonstrates AGPC's commitment to quality and its focus on continuous improvement of its manufacturing processes. Furthermore, this reinforces its place at the forefront of LSAW pipe manufacturing technology in the Middle East. “The Industry 4.0 Digital Leader certification is an important milestone for AGPC, as we harness technology and make significant contributions to the UAE's manufacturing sector,” said Noritsugu Mifune, CEO of Al Gharbia Pipe Company.“This certification confirms AGPC's leadership in digital transformation and positions us as a top performer within the LSAW steel pipe sector. This was made possible by the innovation, dedication, and teamwork of every member of our organisation, and we will continue to strengthen the UAE's industrialisation efforts as the leading and most technologically advanced LSAW pipe manufacturer in the region.” The Industry 4.0 Digital Leader certification is given by MoIAT to companies that demonstrate advanced digital maturity and leadership in adopting Industry 4.0 technologies, such as AI and machine learning. It signifies that a company is a leader in leveraging state-of-the-art technologies in the areas of operational efficiency, sustainable growth, and industrial competitiveness. This recognition and certification is part of the UAE's National Strategy for Industry and Advanced Technology, also known as Operation 300 Billion. The strategy aims to increase the industrial sector's contribution to national GDP to AED 300 billion by 2031 by transforming the UAE into a global industrial hub. As part of the certification process, AGPC underwent an Industrial Technology Transformation Index (ITTI) assessment. Such assessment is designed to improve industry competitiveness through technology adoption, enable evidence-based policymaking, accelerate innovation in manufacturing, and promote sustainability and efficient resource management. Ramesh Chandra Pathak, General Manager – Operations & Innovations, together with the Innovation Team, played a pivotal role in steering AGPC through the assessment and leading the digital transformation initiatives that resulted in the company's successful certification, officially awarded on 20 September 2025. The assessment noted AGPC's strong adoption of Industry 4.0 technologies. A key feature of its this is that all of AGPC's plant processes are connected through its smart Manufacturing Execution System (MES) 4.0, which executes, monitors, tracks and reports operations on the plant floor in real-time. MES acts as the brain connecting manufacturing and testing processes, as well as adapting production plans and schedules according to real-time conditions on the shop floor. In addition, its ISO/IEC 17025-certified testing laboratory ensures that each pipe conforms to stringent quality standards across all stages of the manufacturing process. AGPC was commended for having a fully integrated production process, encompassing production execution, utilities, sourcing, and sales processes. Furthermore, the company's efforts to improve sustainability, such as establishing emissions reduction and water reuse, were recognised. Since commencing production in 2019, AGPC has continually ramped up its production and quality control capabilities by adopting advanced technologies. Today, its factory can produce up to 360,000 metric tons, or an equivalent of 760 kilometres of pipeline, each year. It uses computer vision technology to detect micro-defects that may escape traditional methods. Through machine learning, these systems continuously learn and improve, ensuring that every pipe meets the highest standards of safety and durability, AGPC is certified to ISO, API, and international standards, and each pipe is custom-engineered to project specifications, including carbon steel pipes up to API X80 grade. Its pipes are used by major oil and gas, industrial, and renewable energy companies in the Middle East and beyond.

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment