Hemp Fabric Manufacturing Plant Setup Cost 2025: Project Report, Machinery And Raw Materials

Setting up a hemp fabric manufacturing plant involves several stages from raw fiber to finished textile. This includes decortication (separating fibers from the stalk), retting (softening and separating fibers), scutching and hackling (cleaning and aligning fibers), followed by spinning the fibers into yarn and finally weaving or knitting into fabric. Key machinery includes decorticators, retting tanks, scutching/hackling machines, spinning frames, and looms. Sourcing high-quality industrial hemp stalks and managing the retting process are crucial.

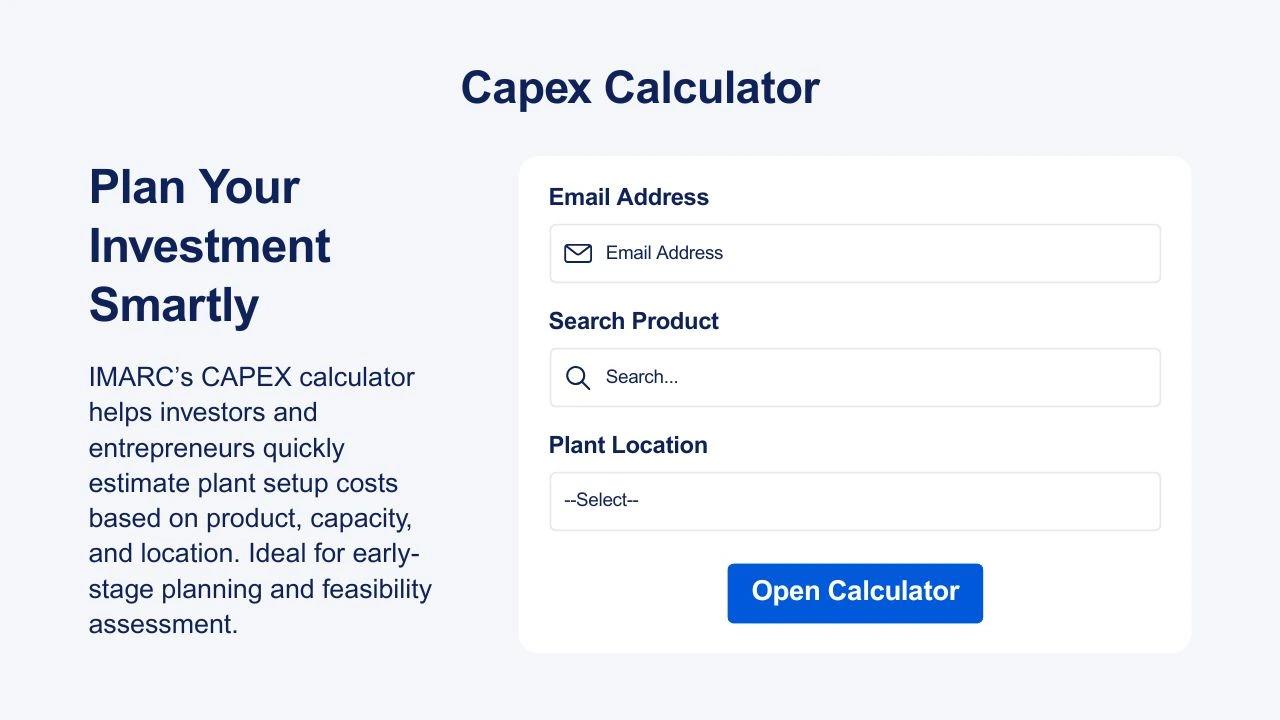

Request for a Sample Report : https://www.imarcgroup.com/hemp-fabric-manufacturing-plant-project-report/requestsample

IMARC Group's “Hemp Fabric Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” offers a detailed and practical guide for entrepreneurs and businesses looking to enter the manufacturing industry. The report includes in-depth analysis of capital investment requirements, project financing options, working capital needs, and projected returns.

This comprehensive business plan outlines every critical step involved in setting up a successful manufacturing plant unit from understanding the industry landscape to planning for real-world challenges. It provides valuable insights into essential components such as hemp fabric manufacturing plant cost, machinery cost, operating cost, raw material requirements, utility needs, infrastructure setup, and packaging logistics.

Hemp Fabric Industry Outlook 2025:

The hemp fabric industry in India is poised for significant growth in 2025. This expansion is driven by increasing consumer awareness of sustainable and eco-friendly textiles, coupled with a growing preference for natural fibers over synthetics. Supportive government initiatives promoting industrial hemp cultivation and processing, along with technological advancements in fiber processing, are expected to boost domestic production and market penetration in fashion, home textiles, and technical textiles.

Key Insights for Hemp Fabric Manufacturing Plant Setup:

Detailed Process Flow:

-

Product Overview

Unit Operations Involved

Mass Balance and Raw Material Requirements

Quality Assurance Criteria

Technical Tests

Project Details, Requirements and Costs Involved:

-

Land, Location and Site Development

Plant Layout

Machinery Requirements and Costs

Raw Material Requirements and Costs

Packaging Requirements and Costs

Transportation Requirements and Costs

Utility Requirements and Costs

Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

-

Capital Investments

Operating Costs

Expenditure Projections

Revenue Projections

Taxation and Depreciation

Profit Projections

Financial Analysis

Profitability Analysis:

-

Total Income

Total Expenditure

Gross Profit

Gross Margin

Net Profit

Net Margin

Request for Customization : https://www.imarcgroup.com/request?type=report&id=12203&flag=E

Key Cost Components of Setting Up a Hemp Fabric Plant:

-

Land and Building Costs: Acquisition or lease of suitable industrial land and construction of a factory building with sections for raw hemp stalk storage, retting, decortication, fiber processing (scutching, hackling), spinning, weaving/knitting, dyeing/finishing, quality control, and warehousing.

Raw Material Procurement: Costs for securing a consistent supply of industrial hemp stalks (bast fiber varieties) from cultivators. This includes transportation from farms.

Utility & Energy Costs: Operational expenses for electricity (for machinery, lighting, HVAC), water (for retting, dyeing, cleaning), and potentially steam or fuel for drying processes.

Labor and Staffing Costs: Salaries for agricultural experts (for sourcing), textile engineers, machine operators, quality control personnel, and skilled labor for various processing stages.

Quality Control and Testing Equipment: Investment in laboratory equipment for testing fiber strength, fineness, yarn count, fabric tensile strength, colorfastness, and other textile properties.

Licenses, Certifications, and Regulatory Compliance: Fees for industrial manufacturing licenses, environmental clearances, and specific permits related to hemp processing. Understanding and complying with regulations concerning industrial hemp cultivation and processing (THC content) is crucial.

Research & Development (R&D): Costs associated with developing new fiber processing techniques, improving fabric softness and drape, or blending hemp with other fibers.

Marketing and Branding: Initial costs for brand development, fabric sampling, participation in textile fairs, and promotional activities to target fashion brands, home textile manufacturers, or direct-to-consumer sales.

Working Capital: Funds for raw material inventory, chemicals, packaging, operational expenses, and salaries until sales revenue stabilizes.

Economic Trends Influencing Hemp Fabric Plant Setup Costs 2025 :

-

Growing Demand for Sustainable Textiles: The increasing global emphasis on eco-friendly and biodegradable materials in the textile industry directly drives demand for hemp fabric, encouraging investment in production capacity.

Government Support for Industrial Hemp: Evolving government policies in India that encourage cultivation and processing of industrial hemp (with low THC content) can provide incentives, subsidies, or easier access to raw materials, impacting setup costs.

Technological Advancements in Fiber Processing: Innovations in decortication, retting, and spinning technologies can improve efficiency and reduce processing costs, though adopting new tech may require higher initial investment.

Fluctuating Raw Material Prices: The price of raw hemp stalks can vary based on agricultural yields, cultivation area, and demand, directly impacting procurement costs for the plant.

Energy Costs: Processing bast fibers and weaving fabric are energy-intensive, making the plant's operational costs sensitive to changes in industrial electricity tariffs.

“Make in India” and Domestic Sourcing: A national push for domestic manufacturing might lead to policies that favor local production, potentially making setup more attractive.

Challenges and Considerations for Investors in Hemp Fabric Plant Projects:

-

Legal and Regulatory Landscape: Navigating the complex and sometimes varying legal framework for industrial hemp cultivation and processing across different states in India can be challenging, especially concerning THC content regulations.

Raw Material Sourcing and Consistency: Ensuring a consistent, high-quality supply of industrial hemp stalks suitable for textile processing can be difficult due to limited large-scale cultivation and variations in fiber quality.

Processing Technology Maturity: While advancing, the industrial-scale processing technologies for hemp bast fibers (especially for fine textiles) are still developing compared to cotton or synthetic fibers, potentially requiring specialized expertise and higher investment.

Retting Process Challenges: Retting, especially traditional water or dew retting, can be time-consuming, weather-dependent, and can generate significant wastewater, posing environmental and logistical challenges.

Competition from Established Fibers: Hemp fabric competes with widely adopted and lower-cost fibers like cotton and synthetics, requiring strong marketing and value proposition to gain market share.

Skilled Workforce: Finding and training a workforce with expertise in hemp fiber processing and textile manufacturing can be a challenge in the nascent Indian industry.

Market Acceptance and Consumer Education: Overcoming historical stigma associated with cannabis and educating consumers about the unique benefits and sustainable attributes of hemp fabric is crucial for market penetration.

Supply Chain Development: Building a robust and efficient supply chain from farm to finished fabric, including logistics for bulky raw materials and specialized processing, requires careful planning.

Conclusion:

The hemp fabric manufacturing industry in India presents a compelling, albeit challenging, investment opportunity for 2025, driven by the surging global demand for sustainable textiles and a supportive policy environment. While establishing a plant involves significant capital investment, navigating evolving regulations, and developing efficient processing technologies and supply chains, the inherent environmental benefits and unique properties of hemp position it for substantial long-term growth. Investors who prioritize technological innovation, sustainable practices, and strategic market positioning will be well-placed to capitalize on this emerging sector.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales[@]imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302 )

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment