Choosing The Right High Speed Pick And Place Robot

February 18, 2025 by Mark Allinson

Choosing the right high speed pick and place robot can revolutionize your business operations. These high speed pick and place robots work tirelessly, increasing productivity and reducing operational costs.

They minimize waste and manual labor expenses, providing significant long-term savings. Their precision reduces defects, ensuring higher yields. By addressing your specific requirements, a high speed pick and place robot enhances both efficiency and profitability.

Key TakeawaysFast pick and place robots work nonstop and can do over 150 tasks per minute. They are great for quick jobs.

To pick the right robot, know what your job needs. Think about how much it can carry, how precise it is, and how easy it fits into your system.

Buying these robots saves money over time. They cut labor costs, lower mistakes, and make work smoother.

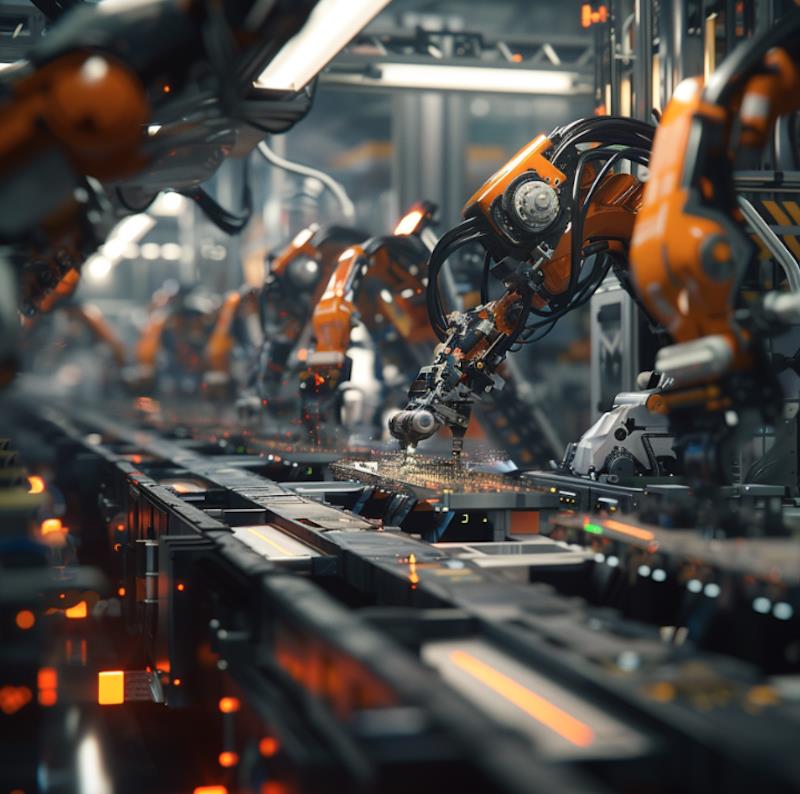

Understanding High-Speed Pick and Place Robots What Are High-Speed Pick and Place RobotsHigh-speed pick and place robots are specialized machines designed to perform repetitive tasks with exceptional speed and precision. These robots excel in moving items from one location to another within a production line.

Unlike other industrial robots, they stand out due to their rapid movements, high accuracy, and ability to integrate seamlessly into existing systems. Their advanced features allow them to handle a variety of components, making them versatile tools for automation.

Common Applications in IndustriesHigh-speed pick and place robots play a vital role in various industries. Their applications include:

-

Handling microchips and other small components.

Packaging products efficiently.

Loading and unloading materials in production lines.

Performing fast-paced assembly tasks.

Delta robots are ideal for high-speed pick-and-place operations involving lightweight objects. Their design features three parallel arms mounted on a triangular base, enabling rapid and precise movements. These robots often use advanced vision systems to sort items by size, color, or shape. They are commonly used in food processing and pharmaceutical packaging , where speed and hygiene are critical.

SCARA RobotsSCARA robots are well-suited for assembly tasks that require force application along the z-axis. Their robust design ensures stability, making them reliable for tasks like packaging and manufacturing. While they may not match the speed of delta robots, they excel in precision and durability.

Articulated RobotsArticulated robots offer flexibility with multiple joints, allowing them to perform complex tasks. These robots are often used in industries requiring intricate movements, such as automotive assembly or metal fabrication. Their versatility makes them a popular choice for diverse applications.

Cartesian RobotsCartesian robots operate on three linear axes, making them highly precise and easy to program. Their simple design is perfect for tasks like inspection, assembly, and material handling. These robots are a cost-effective solution for applications requiring accurate positioning.

Key Selection Criteria for Choosing the Right Industrial Robot Application Requirements and Industry NeedsWhen you choose the right industrial robot, understanding your application requirements is essential. Different industries prioritize unique features based on their operational needs. For instance:

-

Industries handling fragile or precise components, like electronics or pharmaceuticals, demand robots with high accuracy and repeatability.

Sectors dealing with less sensitive parts may focus on speed and cycle time to maximize throughput.

Ease of integration into existing production lines is another critical factor. Robots with user-friendly programming interfaces can reduce setup costs and operational delays.

By aligning the robot's capabilities with your industry-specific needs, you can ensure optimal performance and efficiency.

Payload Capacity and SpeedThe payload and reach of a pick and place robot directly impact its suitability for your tasks. A robot like the QJR12-1700, with a 12kg payload and 1792mm reach, is ideal for handling medium-weight items across various industries.

Evaluate the speed and cycle time as well. High-speed pick and place robots can achieve cycle times as low as 0.33 seconds, ensuring rapid task completion without compromising precision.

Accuracy and RepeatabilityAccuracy and repeatability are vital for maintaining consistent quality in robotic automation. Robots with repeatability as precise as ±0.02mm excel in tasks requiring meticulous placement.

While high-precision robots may cost more, they are indispensable for industries like electronics and pharmaceuticals. For less demanding applications, you can opt for robots with moderate accuracy to save costs.

Space Constraints and Robot FootprintConsider the available space in your facility. Compact robots with flexible installation options, such as ground or inverted mounting, can adapt to tight spaces. This flexibility ensures that the robot integrates seamlessly into your production line without requiring extensive modifications.

Safety Features and ComplianceSafety is non-negotiable when implementing robotic automation. Look for robots equipped with safety mechanisms like light curtains, emergency stops, and sensors to prevent collisions. Compliance with standards such as ANSI/RIA R15.06 and ISO 10218 ensures safe operation and reduces risks to human workers.

Budget and Total Cost of OwnershipThe total cost of ownership includes more than just the initial purchase price. Consider integration costs, safety mechanisms, maintenance fees, and training expenses. Balancing upfront costs with long-term savings is crucial for making a cost-effective decision.

Ease of Integration and ProgrammingModern pick-and-place robots often feature intuitive programming interfaces, eliminating the need for advanced robotics knowledge. However, achieving synchronized and precise movements requires skilled integration.

Many suppliers offer training and support to help you optimize the robot's performance. Choosing a robot that integrates easily with your existing systems can minimize downtime and ensure a smooth transition.

Benefits of High-Speed Pick and Place Robots Increased Speed and ProductivityHigh-speed pick and place robots significantly enhance productivity by operating continuously without breaks. Unlike human workers, these robots maintain consistent performance throughout the day.

They achieve speeds exceeding 150 cycles per minute, far surpassing traditional robotic systems that typically operate at 30 to 60 cycles per minute. This remarkable speed ensures high throughput, making them ideal for fast-paced tasks like product packaging and assembly.

By integrating a high-speed pick and place robot into your operations, you can reduce operational costs while boosting overall efficiency.

Enhanced Precision and ConsistencyPrecision is a hallmark of pick-and-place robots. These robots achieve placement accuracies within 0.1 mm, ensuring tight tolerances and minimal defect rates. For example, they excel in repetitive tasks like electronic component assembly , where accuracy is critical.

Traditional systems cannot match this level of precision, often leading to higher error rates. With robotic automation, you can deliver consistently high-quality outcomes, giving your business a competitive edge.

-

Operates at speeds exceeding 150 cycles per minute.

Achieves placement accuracies within 0.1 mm.

Reduces human error, ensuring consistent results.

Investing in a pick and place robot leads to long-term cost savings . These robots reduce labor costs by performing tasks faster and more accurately than humans. Their ability to minimize defects also lowers material waste, further cutting expenses.

Additionally, their continuous operation eliminates downtime, maximizing efficiency. Over time, the savings from reduced errors and increased productivity outweigh the initial investment.

Scalability and Flexibility for Future NeedsHigh-speed pick and place robots adapt easily to changing business needs. Their reprogrammable nature allows you to switch tasks or adjust processes with minimal downtime.

This flexibility supports production scaling and ensures your operations remain agile. Compared to traditional automation, these robots offer superior adaptability and speed, making them a future-proof solution for your business.

By choosing a high-speed pick and place robot, you prepare your business for growth and evolving market demands.

Choosing the right high-speed pick and place robot ensures your business achieves optimal efficiency and productivity. Align the robot's features with your specific needs to maximize its value. Evaluate long-term ROI carefully. While the initial investment may seem high, automation often recoups costs within 1-3 years through reduced waste and labor expenses.

To simplify your decision-making process, create a checklist. Start by identifying areas for improvement in your operations. Set measurable goals, research equipment that meets your requirements, and prepare your workspace for integration. Consult experts to ensure you select the best robot for your needs.

Finally, consider factors like maintenance, support, and ease of integration. These elements ensure smooth operations and long-term success. By following these steps, you can make an informed decision that benefits your business for years to come.

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment