Nanomembrane Unlocks Sharper Lithium Extraction

Researchers at Rice University have unveiled a nanocomposite membrane that isolates lithium selectively from brines faster and with far lower waste than existing methods, presenting a potential paradigm shift for battery supply chains.

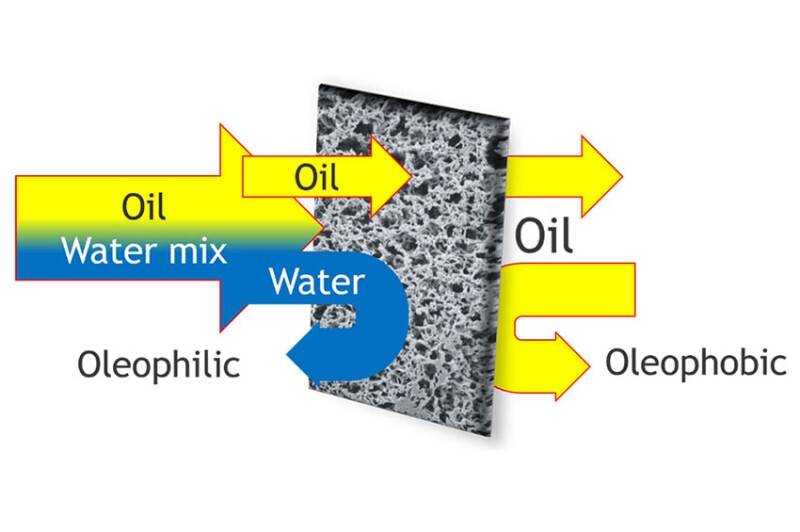

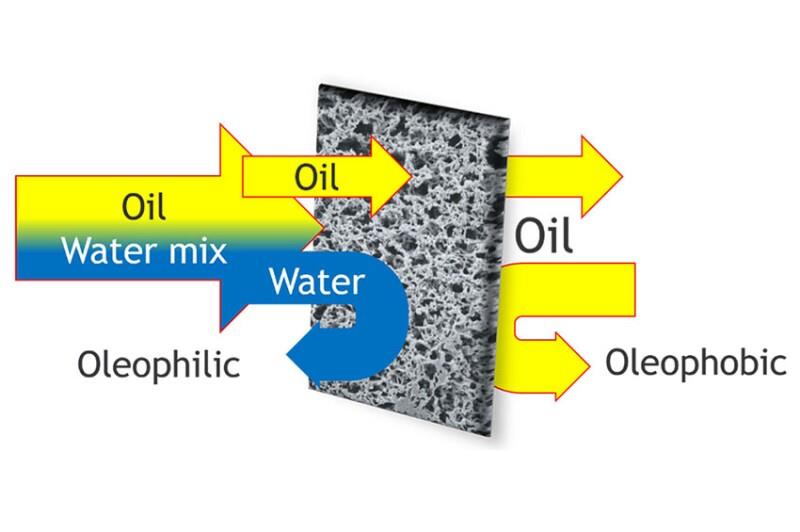

The membrane leverages a three-layer architecture embedded with lithium titanium oxide nanoparticles, enabling lithium ions to pass while rejecting more prevalent ions such as sodium, calcium and magnesium. Under an applied electrical field in an electrodialysis setup, the system drives lithium transport across the membrane with high selectivity and stability. Rigorous tests over two weeks show the membrane retains performance without substantial degradation.

Conventional lithium extraction from brine relies heavily on evaporation ponds and chemical precipitation steps that can span over a year, consume large volumes of water, and generate substantial chemical waste. The Rice team says their design slashes water use, reduces waste streams, and accelerates the extraction process.

Qilin Li, co-director of Rice's Nanotechnology Enabled Water Treatment Centre, explained that the key challenge has always been separating lithium effectively from competing cations. The innovation lies in grafting amine groups onto the embedded LTO particles, which enables a uniform integration into a polyamide matrix and eliminates defects that typically plague mixed inorganic–polymer membranes. By tuning each of the membrane's three layers independently, the researchers can optimise trade-offs among permeability, selectivity and mechanical robustness.

Computational modelling played a central role. Researchers simulated ion transport at the atomic scale to refine their design principles and understand how lithium ions shed hydration shells to migrate through the LTO lattice. The simulations and laboratory results show that although lithium is only a minor ionic species in brine, the membrane enables it to cross preferentially under the electric field, while other ions remain excluded.

See also Jane Goodall: A Life Among Chimpanzees and Hope for Our PlanetJulian Lou, a professor of materials science and nanoengineering at Rice, emphasised the technology's up-scaling prospects, noting that the membrane is compatible with existing industrial electrodialysis setups. That means retrofit potential for operators already employing electrochemical systems in desalination or wastewater treatment.

The team also notes that the same design strategies could extend to extracting other critical metals such as cobalt and nickel. By altering nanoparticle chemistry or lattice structures, the membrane layers could be adapted to target different ionic species from complex mixtures.

The breakthrough builds on a decade of foundational work at Rice in nanomaterials and membrane engineering. The researchers credit their success to cumulative advances in interface chemistry, nanocomposite stability, and materials simulation.

Challenges remain. Long-term durability in real brine environments over months or years must be validated, particularly under fluctuating temperatures, fouling conditions, and chemical stresses. Scale-up economics must still demonstrate cost competitiveness against entrenched evaporation and conventional electrodialysis systems. Some critics may point to risks in membrane fouling, nanoparticle leaching, or maintenance costs when deployed at industrial scale.

Notice an issue? Arabian Post strives to deliver the most accurate and reliable information to its readers. If you believe you have identified an error or inconsistency in this article, please don't hesitate to contact our editorial team at editor[at]thearabianpost[dot]com . We are committed to promptly addressing any concerns and ensuring the highest level of journalistic integrity. Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Most popular stories

Market Research

- Pepeto Highlights $6.8M Presale Amid Ethereum's Price Moves And Opportunities

- Codego Launches Whitelabel Devices Bringing Tokens Into Daily Life

- Zeni.Ai Launches First AI-Powered Rewards Business Debit Card

- LYS Labs Moves Beyond Data And Aims To Become The Operating System For Automated Global Finance

- Whale.Io Launches Battlepass Season 3, Featuring $77,000 In Crypto Casino Rewards

- Ceffu Secures Full VASP Operating License From Dubai's VARA

Comments

No comment