AI-Powered Inspections In Field Robotics Go Beyond Automation

September 8, 2025 by Mai Tao

The Hidden Weakness of AutomationAt first glance, many workshops give the impression that machines are running the show. A welding arm sends out brief showers of sparks, a drone hovers around a steel beam, and a small transport unit winds its way between stacks of pallets.

From a distance it looks like a closed system without weak points. A closer look tells another story.

Motors that run smoothly for most of the shift can hide tiny fractures that end in sudden stoppage. In one automotive plant, a single unnoticed crack in a gearbox housing forced an entire line to shut down for two days.

A drone may bring back hundreds of inspection photos, but without proper review they remain just files on a server. These gaps are not rare exceptions. When they appear, they interrupt production and in some cases pose real risks to the workforce.

Robots Can Work. But Can They Inspect?Automation usually thrives when the task never changes. Think of robots on a line: they can weld the same joint over and over, lift crates all day, or screw bolts without ever slowing down. Inspections don't fit that mold. They're messy, they ask for interpretation, not just movement.

Take a thermal camera reading. One day the hotspot is nothing, just a quirk in the data. Another day it's the early sign that a motor is about to give up.

Or consider vibration sensors: half the time you're just hearing the hum of the room, and the other half it's a bearing that's on its last legs. Even drones, which spot cracks nobody else can reach, won't tell you if what they see is harmless cosmetic wear or a dangerous fault inside the structure.

None of this breaks down into yes or no. It takes judgment, context, and the kind of flexibility that machines built for repetition simply don't have.

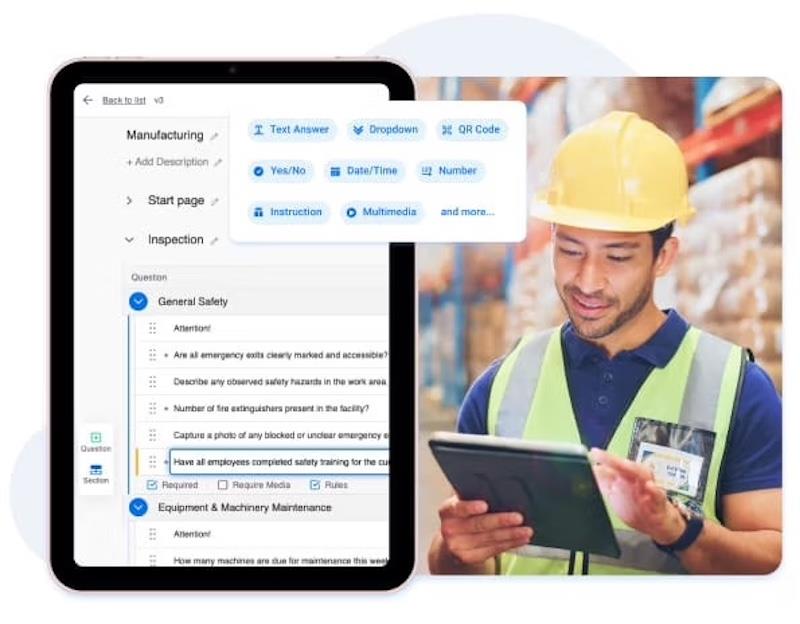

The Critical Step: AI-Powered ChecklistsThis is where inspections break free from automation and step into intelligence. The missing link is not more robots or more sensors; it's the framework that makes their findings meaningful.

Enter AI-powered checklists.Unlike static forms, these checklists evolve in real time. If a robot detects a vibration anomaly, the checklist doesn't just log it; it updates the workflow, cross-references historical data, and prompts specific corrective actions.

If a drone identifies a thermal irregularity, the checklist suggests whether to escalate, monitor, or discard the reading.

In doing so, AI-powered checklists ( ) transform inspections from a passive exercise into an adaptive process. They connect robotic observations with human expertise, ensuring nothing slips through the cracks.

Field Stories: Where Intelligence Meets Reality. (88% AI)

Offshore Wind FarmsOut in the North Sea, a drone hovers close to a turbine blade that has been hammered for months by salt spray and strong winds. The robot's camera captures one surface after another, sometimes hundreds of photos before the battery runs low.

A climbing unit follows, scratching its way higher to reach spots that humans would need ropes for. The result is a mountain of raw images.

Instead of asking engineers to sift through every single file, the material is run through an AI-based checklist system that marks suspicious patterns and links them to older inspection records. What reaches the control room onshore is not noise, but a short list of findings that demand attention.

Subsea PipelinesOn the seabed the conditions are harsher. Small crawler robots move slowly along a steel pipeline, headlights cutting through murky water. Their job is to spot corrosion before it eats through the wall.

In a single shift, the machines can record several hours of video, most of it uneventful. Reviewing that by hand would take days. Trained AI models scan the footage in real time, highlight irregular spots and attach them straight into digital inspection logs.

A narrow patch of pitting, barely a few millimeters across, can then be traced and documented. Instead of endless reels of video, the operator ends up with a report that is ready to be checked against compliance standards.

Hazardous Industrial SitesChemical plants and high-radiation zones leave little room for human inspectors. Robots carry sensors into areas where no one can stay longer than a few minutes. They pick up signs of gas leaks, record rising surface temperatures, or detect cracks so small they would be invisible without magnification.

Each reading is passed into a checklist that adapts on the fly, so the path of the inspection changes while the robot is still in the field. Workers outside the danger zone stay safe, and the plant manager receives a detailed log that shows not just the anomalies, but also the exact conditions under which they were found.

Why Smart Inspections Redefine AdvantageCompanies that rethink inspections are not just chasing efficiency metrics. They are building systems that bend less under pressure, adapt faster to surprises, and recover quicker when problems do surface.

Downtime AvoidanceCatching anomalies before they grow into failures is the difference between tightening a loose bolt during a shift change and shutting down an entire line for three days. AI-driven inspections make those small saves routine instead of relying on luck.

Safer OperationsLetting robots take on the jobs that involve height, heat, or confined spaces reduces the risk to people. The role of AI is to interpret what those robots see, so human expertise can shift toward oversight and decisions rather than physical exposure.

Compliance with EvidenceWhen every observation is logged in a structured checklist, there is no scramble to reconstruct what happened. Regulators see a clear trail from anomaly to decision to action, and internal reviews can rely on facts instead of memory.

The edge does not come from the size of a robot fleet, but from how well their findings are turned into insight and action.

From Automation to IntelligenceThe history of industry is full of milestones: first came the machines that replaced muscle, then the systems that automated repetitive work. Now we are entering another phase, one that is less about speed and more about understanding.

Picture a robot sliding through a pipeline. It can reach places no human wants to crawl into. But what does it do with what it sees? That is where artificial intelligence and structured digital checklists step in, turning raw signals into explanations and, finally, into actions that someone can trust.

It is no longer just about getting the job done quickly. It is about creating a loop where every observation is captured, interpreted, and written down in a way that can be acted on later.

Future-Proofing Through Intelligent InspectionsAutomation has brought industry a long way, but in inspections it quickly hits a wall. Robots can gather endless footage, scans, and readings. AI can sort through the noise and highlight patterns. Yet without a framework that puts those findings into context, the information often sits unused.

What makes the difference is the combination: robotics for reach, AI for interpretation, and intelligent checklists to keep the process disciplined. In practice, this means that a single crack on a turbine blade is not just spotted, but documented, flagged, and scheduled for repair.

That shift, from“we saw something” to“we acted on it”, is what will define the next era of inspections. Because while automation may deliver speed, intelligence is what builds trust.

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment