Ferric Sulfate Production Plant Setup Report 2025, Machinery, Cost Analysis & Requirements

Establishing a ferric sulfate production plant requires secure access to raw materials such as iron scrap and sulfuric acid, a corrosion-resistant reactor system, efficient filtration units, and quality control laboratories. Strategic site selection near industrial zones or water treatment facilities can reduce logistics costs, while adherence to environmental and safety regulations ensures sustainable operations.

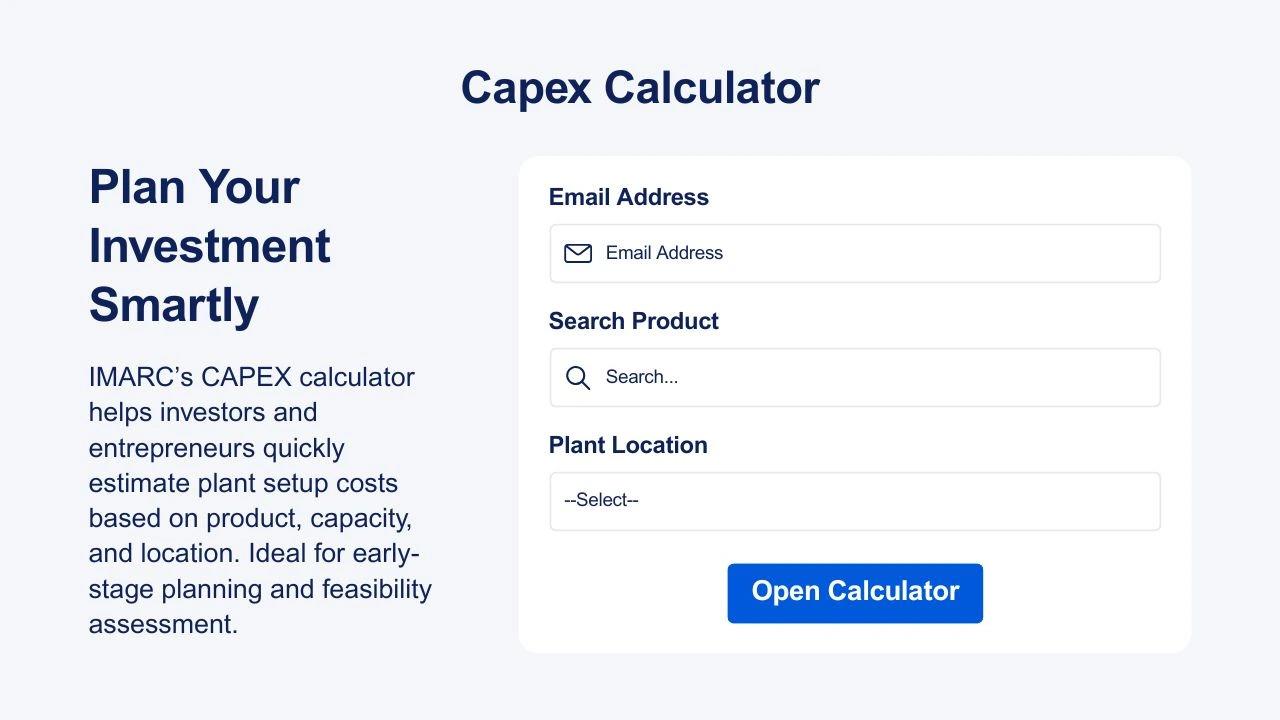

IMARC Group's report, titled “ Ferric Sulfate Production Cost Analysis Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue,” provides a complete roadmap for setting up a ferric sulfate production plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Request for a Sample Report : https://www.imarcgroup.com/ferric-sulfate-manufacturing-plant-project-report/requestsample

Ferric Sulfate Industry Outlook 2025:

The ferric sulfate industry in 2025 is expected to witness steady growth, driven by increasing demand for efficient water and wastewater treatment solutions amid tightening environmental regulations. Expanding urbanization and industrialization, particularly in emerging economies, are boosting consumption in municipal and industrial sectors. Additionally, the compound's use in pigments, textiles, and electronics supports market diversification. Technological advancements in production processes and a shift toward eco-friendly treatment chemicals are likely to enhance efficiency and reduce costs, further strengthening market competitiveness. However, fluctuations in raw material prices and stringent handling requirements may pose operational challenges.

Key Insights for Ferric Sulfate Production Plant Setup:

Detailed Process Flow:

-

Product Overview

Unit Operations Involved

Mass Balance and Raw Material Requirements

Quality Assurance Criteria

Technical Tests

Project Details, Requirements and Costs Involved:

-

Land, Location and Site Development

Plant Layout

Machinery Requirements and Costs

Raw Material Requirements and Costs

Packaging Requirements and Costs

Transportation Requirements and Costs

Utility Requirements and Costs

Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

-

Capital Investments

Operating Costs

Expenditure Projections

Revenue Projections

Taxation and Depreciation

Profit Projections

Financial Analysis

Profitability Analysis:

-

Total Income

Total Expenditure

Gross Profit

Gross Margin

Net Profit

Net Margin

Key Cost Components of Setting Up a Ferric Sulfate Plant :

-

Raw Materials – Procurement of iron scrap, iron oxides, and sulfuric acid.

Production Equipment – Corrosion-resistant reactors, mixers, filtration units, and drying systems.

Utilities – Electricity, water supply, steam generation, and waste treatment systems.

Labor Costs – Skilled and unskilled workforce for production, quality control, and maintenance.

Infrastructure & Construction – Plant buildings, storage facilities, piping, and safety installations.

Environmental Compliance – Pollution control equipment, effluent treatment systems, and regulatory permits.

Logistics & Supply Chain – Transportation, storage, and handling of raw materials and finished products.

Quality Control & R&D – Laboratory equipment, testing materials, and process optimization.

Economic Trends Influencing Ferric Sulfate Plant Setup Costs 2025 :

-

Raw Material Price Volatility – Fluctuations in iron scrap and sulfuric acid prices due to global supply-demand imbalances.

Energy Cost Variations – Rising electricity and fuel prices impacting production and operational expenses.

Inflationary Pressures – Increased costs of construction materials, labor, and equipment procurement.

Environmental Regulation Compliance – Stricter environmental standards requiring advanced pollution control investments.

Technological Advancements – Adoption of modern, energy-efficient production methods reducing long-term costs but raising initial capital expenditure.

Currency Exchange Rate Fluctuations – Impacting import costs for specialized equipment and raw materials.

Infrastructure Development Trends – Government investments in industrial zones potentially lowering setup costs through shared facilities.

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=10142&flag=E

Challenges and Considerations for Investors in Ferric Sulfate Plant Projects:

-

Regulatory Compliance – Adhering to stringent environmental, safety, and waste management regulations.

Market Demand Fluctuations – Dependence on water treatment and industrial sectors susceptible to economic cycles.

Raw Material Supply Risks – Potential shortages or price spikes in iron and sulfuric acid.

Capital Intensity – High initial investment in specialized, corrosion-resistant equipment and infrastructure.

Operational Expertise – Requirement for skilled workforce and technical know-how in chemical manufacturing.

Environmental Impact Management – Handling of acidic effluents and solid by-products.

Competition and Pricing Pressure – Presence of established suppliers influencing market entry strategies.

Conclusion:

The establishment of a ferric sulfate production plant in 2025 presents both promising opportunities and notable challenges. Rising global demand for efficient water and wastewater treatment solutions, coupled with diversified industrial applications, underpins strong market potential. However, success in this sector requires careful navigation of raw material volatility, regulatory compliance, and significant capital requirements. Strategic site selection, adoption of advanced production technologies, and robust supply chain management can enhance operational efficiency and competitiveness. For investors, thorough market analysis and long-term planning are essential to maximize returns while ensuring environmental and economic sustainability.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales[@]imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment