Japan On Edge Of EUV Lithography Chip-Making Revolution

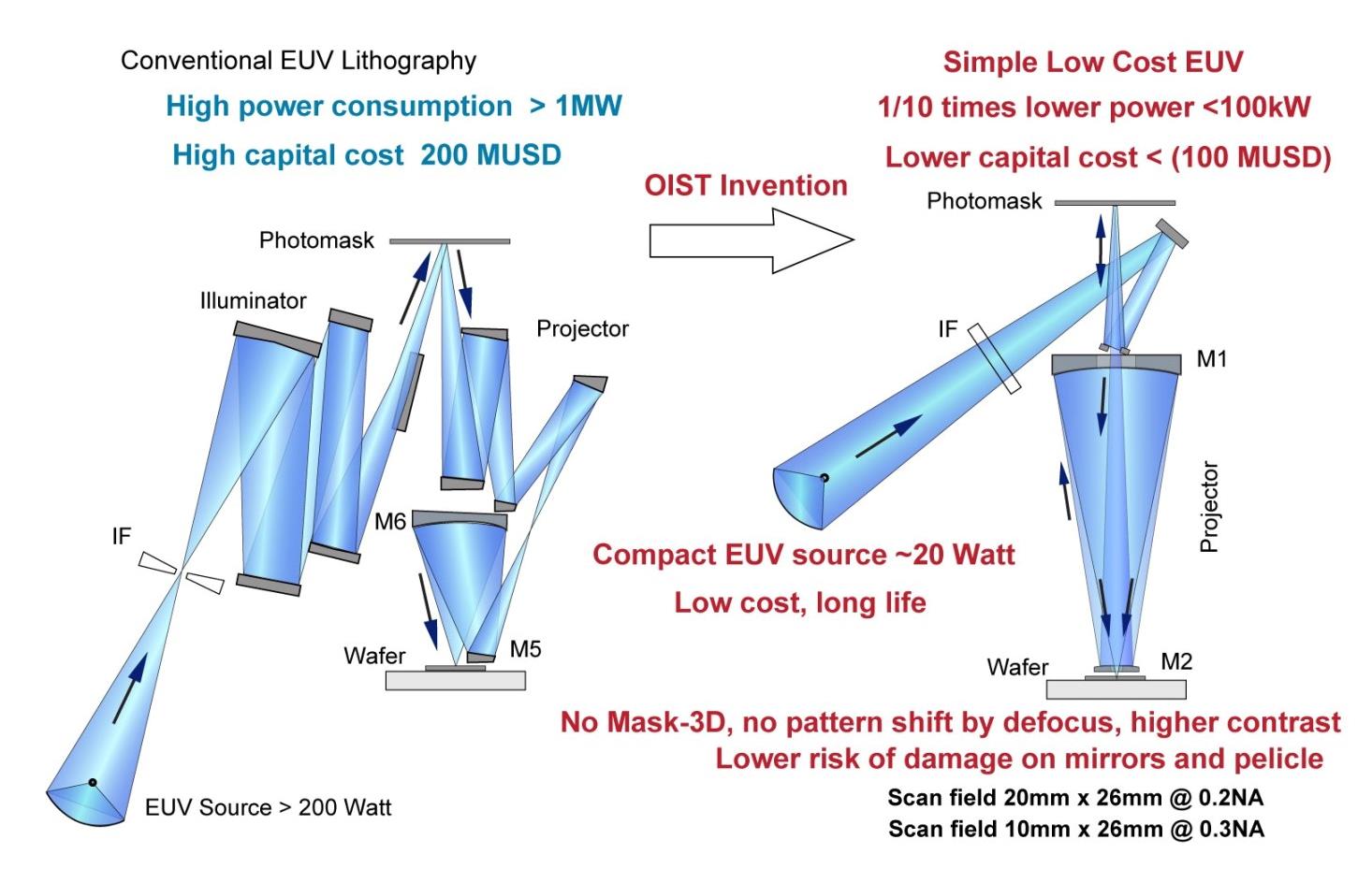

According to reports, the EUV equipment's optical system is greatly simplified while power consumption is reduced by a factor of ten, raising the prospect of much cheaper advanced chip-making machines.

If so, it could mark the end of ASML's monopoly on EUV lithography, which would have serious implications for semiconductor manufacturers, investors and governments.

Recall that US sanctions forbid the sale of EUV lithography equipment to China, making it much more difficult and expensive for Chinese companies to make semiconductors at 7nm and 5nm, and impossible at the 3nm node now in production at Taiwan's TSMC and the 2nm and smaller nodes currently under development.

AI processors, the low-power semiconductor devices used in smartphones, and the latest high-density memory chips are made using highly complex EUV lithography equipment that is expensive to maintain and consumes enormous amounts of power.

OIST Professor Tsumoru Shintake says the invention is a breakthrough technology that can nearly completely solve these problems.

OIST's Tsumoru Shintake. Image: OIST

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment