Tea Processing Plant Setup Cost Report Covers Project Economics, Business Plan And Machineries Requirement

Setting up a tea processing plant requires careful planning of location, equipment, and capacity. Key steps include securing raw leaf supply, installing withering, rolling, oxidation, drying, and packaging machinery, ensuring compliance with food safety regulations, and establishing quality control systems. Efficient workflow design and skilled labor are critical for consistent production and competitive market entry.

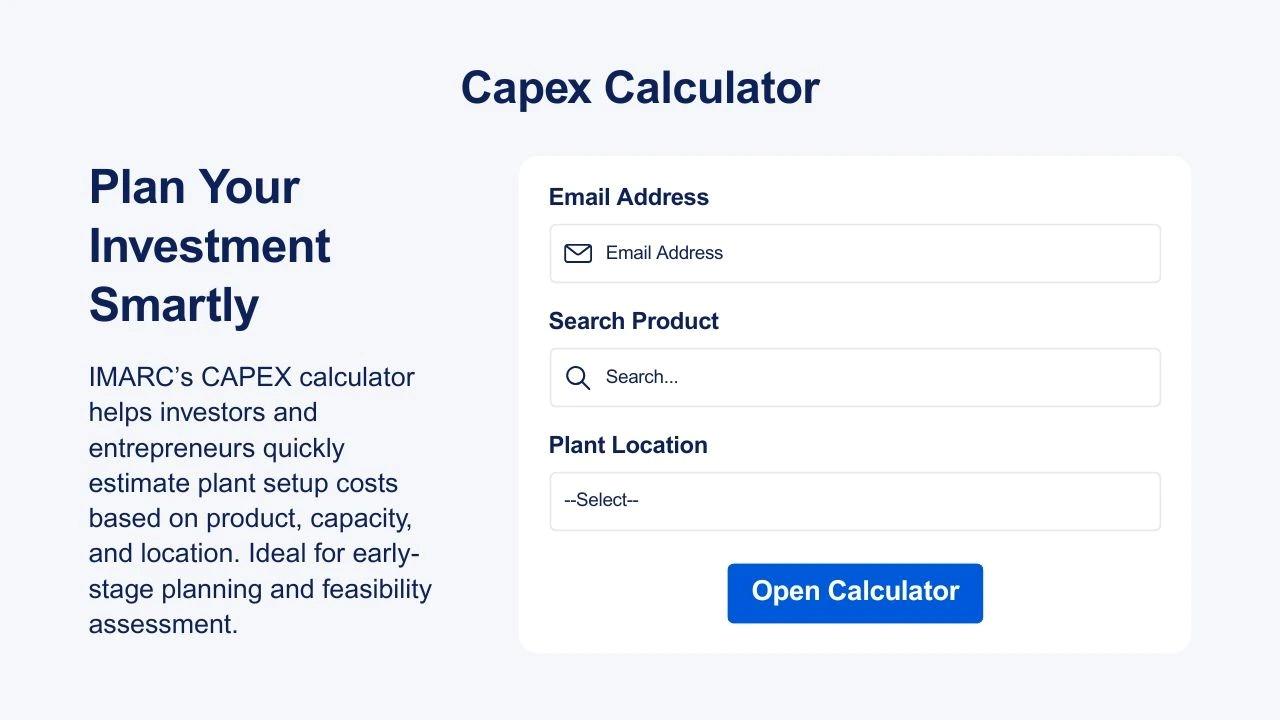

IMARC Group's report, titled “ Tea Processing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue,” provides a complete roadmap for setting up a tea processing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Request for a Sample Report : https://www.imarcgroup.com/tea-processing-plant-project-report/requestsample

Tea Industry outlook 2025:

The tea industry outlook for 2025 indicates steady growth driven by rising health consciousness, premiumization, and expanding demand for specialty and herbal blends. Global consumption is expected to increase, supported by emerging markets and younger demographics embracing innovative flavors and functional teas. Sustainability, ethical sourcing, and organic certifications are gaining prominence, influencing consumer preferences and brand positioning. Technological advancements in processing and packaging are enhancing product quality and shelf life. E-commerce and direct-to-consumer channels are projected to strengthen market reach, while competition among established and niche brands is expected to intensify, encouraging product differentiation and value-added offerings.

Key Insights for Tea Processing Plant Setup:

Detailed Process Flow:

-

Product Overview

Unit Operations Involved

Mass Balance and Raw Material Requirements

Quality Assurance Criteria

Technical Tests

Project Details, Requirements and Costs Involved:

-

Land, Location and Site Development

Plant Layout

Machinery Requirements and Costs

Raw Material Requirements and Costs

Packaging Requirements and Costs

Transportation Requirements and Costs

Utility Requirements and Costs

Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

-

Capital Investments

Operating Costs

Expenditure Projections

Revenue Projections

Taxation and Depreciation

Profit Projections

Financial Analysis

Profitability Analysis:

-

Total Income

Total Expenditure

Gross Profit

Gross Margin

Net Profit

Net Margin

Key Cost Components of Setting Up a Tea Plant :

-

Land Acquisition and Site Development – Cost of purchasing or leasing land, site preparation, and infrastructure development.

Building and Civil Works – Construction of processing units, storage facilities, offices, and utilities.

Machinery and Equipment – Investment in withering troughs, rollers, oxidizers, dryers, sorting machines, and packaging systems.

Raw Material Procurement – Initial cost for securing fresh tea leaves or establishing plantations.

Utilities and Installation – Power supply, water systems, waste management, and machinery installation.

Labor and Training – Recruitment, wages, and skill development for plant operations.

Licensing and Compliance – Fees for regulatory approvals, certifications, and quality control systems.

Working Capital – Funds for initial operations, inventory, and operational expenses.

Economic Trends Influencing Tea Plant Setup Costs 2025 :

-

Inflationary Pressures – Rising costs of construction materials, machinery, and labor due to global inflation.

Energy Price Volatility – Fluctuations in electricity and fuel prices impacting processing and transportation expenses.

Currency Exchange Rates – Variations in exchange rates affecting the import cost of equipment and packaging materials.

Interest Rate Changes – Higher borrowing costs influencing capital expenditure and financing.

Global Supply Chain Disruptions – Delays and higher freight costs for imported machinery and raw materials.

Sustainability Compliance Costs – Investments required to meet environmental regulations and obtain certifications.

Technological Upgrades – Additional spending on automation, quality monitoring, and energy-efficient systems.

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=7330&flag=C

Challenges and Considerations for Investors in Tea Plant Projects:

-

Market Price Volatility – Fluctuating tea prices due to supply-demand imbalances and climate conditions.

Climatic and Environmental Risks – Dependency on favorable weather patterns and vulnerability to pests or crop diseases.

High Initial Capital Requirement – Significant upfront investment in land, infrastructure, and machinery.

Regulatory and Compliance Hurdles – Complex licensing processes, food safety standards, and environmental regulations.

Labor Availability and Skills – Need for skilled workforce in tea processing and potential labor shortages.

Quality Control Demands – Maintaining consistent quality to meet domestic and export market standards.

Competitive Market Landscape – Intense competition from established players and low-cost producers.

Conclusion:

The establishment of a tea processing plant in 2025 presents both promising opportunities and notable challenges. Growing global demand, driven by health-conscious consumers and expanding specialty tea segments, creates favorable market conditions. However, investors must account for rising setup costs influenced by economic trends, regulatory requirements, and technological advancements. Strategic planning, efficient resource allocation, and adherence to quality and sustainability standards are essential for long-term viability. Success in this sector depends on balancing cost management with innovation, brand differentiation, and market responsiveness to ensure competitiveness in a dynamic and evolving tea industry landscape.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales[@]imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment