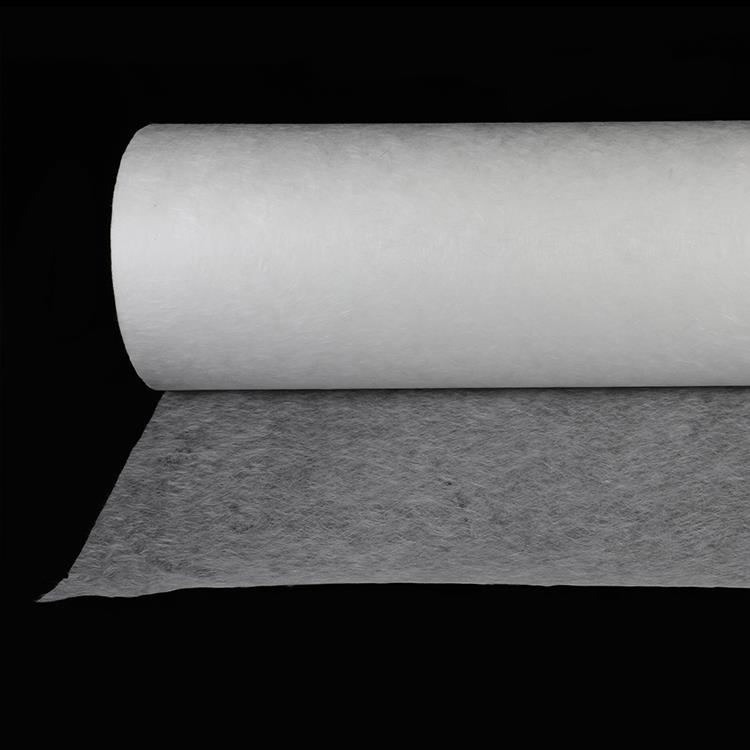

Fiberglass Surface Tissue Vs. Chopped Strand Mat: Which Is Better?

| Factor | Fiberglass Surface Tissue | Chopped Strand Mat (CSM) |

| Thickness | 10-50 gsm (thin) | 300-600 gsm (thick) |

| Strength | Surface smoothness | Structural reinforcement |

| Resin Usage | Low (resin-rich layer) | High (soaks up resin) |

| Cost | More expensive per m2 | Cheaper per m2 |

| Ease of Use | Requires skill for smooth finish | Easy to handle, good for beginners |

| Best For | Aesthetic finishes, corrosion resistance | Structural builds, repairs |

4. Which One Should You Choose?

. Choose Fiberglass Surface Tissue If...

You need a smooth, professional finish (e.g., car bodywork, yacht hulls).

You want to prevent print-through in gel-coated surfaces.

Your project requires chemical resistance (e.g., chemical tanks).

. Choose Chopped Strand Mat If...

You need thick, structural reinforcement (e.g., boat floors, storage tanks).

You're on a budget (CSM is cheaper per square meter).

You're a beginner (easier to handle than surface tissue).

5. Expert Tips for Using Both Materials

For Fiberglass Surface Tissue :

--- Use with epoxy or polyester resin for best adhesion.

--- Apply as the final layer for a smooth finish.

--- Roll out evenly to avoid wrinkles.

For Chopped Strand Mat :

--- Wet out thoroughly-CSM absorbs more resin.

--- Use multiple layers for added strength.

--- Ideal for hand lay-up and spray-up applications.

6. Industry Trends & Future Developments

Hybrid Solutions: Some manufacturers now combine surface tissue with CSM for balanced strength & finish.

Eco-Friendly Binders: New bio-based binders are making fiberglass materials more sustainable.

Automated Lay-Up: Robotics are improving precision in applying thin surface tissues.

Conclusion: Which is the Winner?

There's no single "best" material-fiberglass surface tissue excels in finish quality, while chopped strand mat is better for structural builds.

For most projects:

Use CSM for bulk reinforcement (e.g., boat hulls, tanks).

Add surface tissue as a final layer for a smooth, professional look.

By understanding their differences, you can optimize costs, strengths, and aesthetics in your fiberglass projects.

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment