(MENAFN- Asia Times) In mid-April, G7 ministers will gather in Sapporo for discussions on issues relating to climate, energy and the environment. The choice of Hokkaido as the venue for this meeting is no accident.

The northernmost of Japan's four main islands, Hokkaido is well known for its resplendent and diverse natural attributes. Perhaps less well-known are the efforts Hokkaido is making to achieve carbon neutrality and contribute to the reduction of global greenhouse gases. The prefecture is aiming to earn the monicker“Zero Carbon Hokkaido” by 2050, by leveraging its forest absorption capacity and natural resources suitable to renewable energy production.

The island is also home to high-tech sustainability projects ranging from carbon capture and storage (CCS) to the development of solar panel component recycling technology.

The power of renewable energy

Situated between Sapporo, Hokkaido's capital city, and Ishikari Bay, the city of Ishikari effectively serves as the port for Sapporo. Seven years ago, it began developing Ishikari Bay New Port. The 100-hectare portside industrial park will ultimately host over 760 companies, including energy-intensive industries such as data centers as well as warehousing, logistics, manufacturing and large-scale commercial stores. It will have a working population of more than 20,000.

As part of its effort to decarbonize industry and promote sustainability, the park's electricity needs will be met entirely by wind, solar and biomass power generated by facilities also situated at the site or immediately offshore. There are already facilities capable of producing a steady 300 megawatts of power. A planned offshore wind farm gives the facilities the potential to produce as much as 3.6 gigawatts by 2025, enabling the complex to also provide local renewable energy across the region.

A much smaller renewable energy project lies on the coast about 30 kilometers north of Ishikari Bay New Port in the Atsuta district of Ishikari city. It is a local energy production project centered on the development of a microgrid to provide renewable energy in case of emergency.

Atsuta's microgrid facilities produce renewable energy for emergency use. Photo: Vickie L. Beyer

The project generates solar power as well as producing hydrogen through electrolysis. An energy management system consisting of onsite storage batteries ensures energy can be produced at a steady rate. The district was chosen for this experimental project because it is prone to being cut off during storms and extreme weather. The microgrid ensures that the area can have more than 72 hours of energy even when this occurs. At present the EMS powers the local fire station, a local school, its lunch center, and a roadside station facility.

Inside Sapporo, another kind of microgrid project cools the Glass Pyramid of the city's Moroenuma Park. The park, which opened in 2005, is situated on a former landfill site. Designed by famed landscape architect Isamu Noguchi with the predominant shape of pyramids, the Glass Pyramid is by far its most iconic feature.

In summer, the Glass Pyramid is prone to overheating through overexposure to the sun's rays. Rather than using electric air conditioning, it contains a green-power air conditioning system based on melting snow, which is gathered into a specially-designed storeroom at the end of every winter. The system uses the slow melting of around 1.5 kilotons of snow to regulate the temperature inside the Glass Pyramid without greenhouse gas emissions. Using thermal energy to accomplish the same task would generate approximately 30,000 kg of carbon dioxide.

Glass Pyramid of Moroenuma Park uses snow-based cooling system. Photo: Vickie L. Beyer

Recycling to reduce waste & carbon emissions

Eliminating CO2 that has already been produced is another essential task if the most harmful effects of global climate change are to be checked.

The Japanese government has sponsored an experimental carbon capture project in

Tomakomai City on Hokkaido's south coast aimed at developing carbon capture and storage technology that can effectively dispose of CO2 without releasing it into Earth's atmosphere. The CCS project, which commenced in April 2016, captures and compresses the CO2 generated at a nearby oil refinery, which it then injects into rock layers beneath the nearby seabed using directional drilling.

Tomakomai was chosen as the site for the facility because of its seismic stability. Multiple monitoring stations in the area keep a close eye on the impact of the CO2 injection on that stability, as well as on the sea life above the injection sites. The project achieved its goal of capturing and storing 300,000 tons of CO2 by November 2019. The facility experimented with injections into both sandstone and volcanic strata. Predictably, sandstone has a far higher absorption capacity, although injection into volcanic strata has also been proven to be possible.

CCS remains somewhat controversial, with critics claiming that polluters are not

discouraged from reducing their emissions when they believe those emissions can be captured and stored. However, this project has demonstrated that it is possible to reduce harmful emissions while cleaner energy sources are being developed and implemented.

Carbon capture and storage facilities at Tomakomai. Photo: Vickie L. Beyer

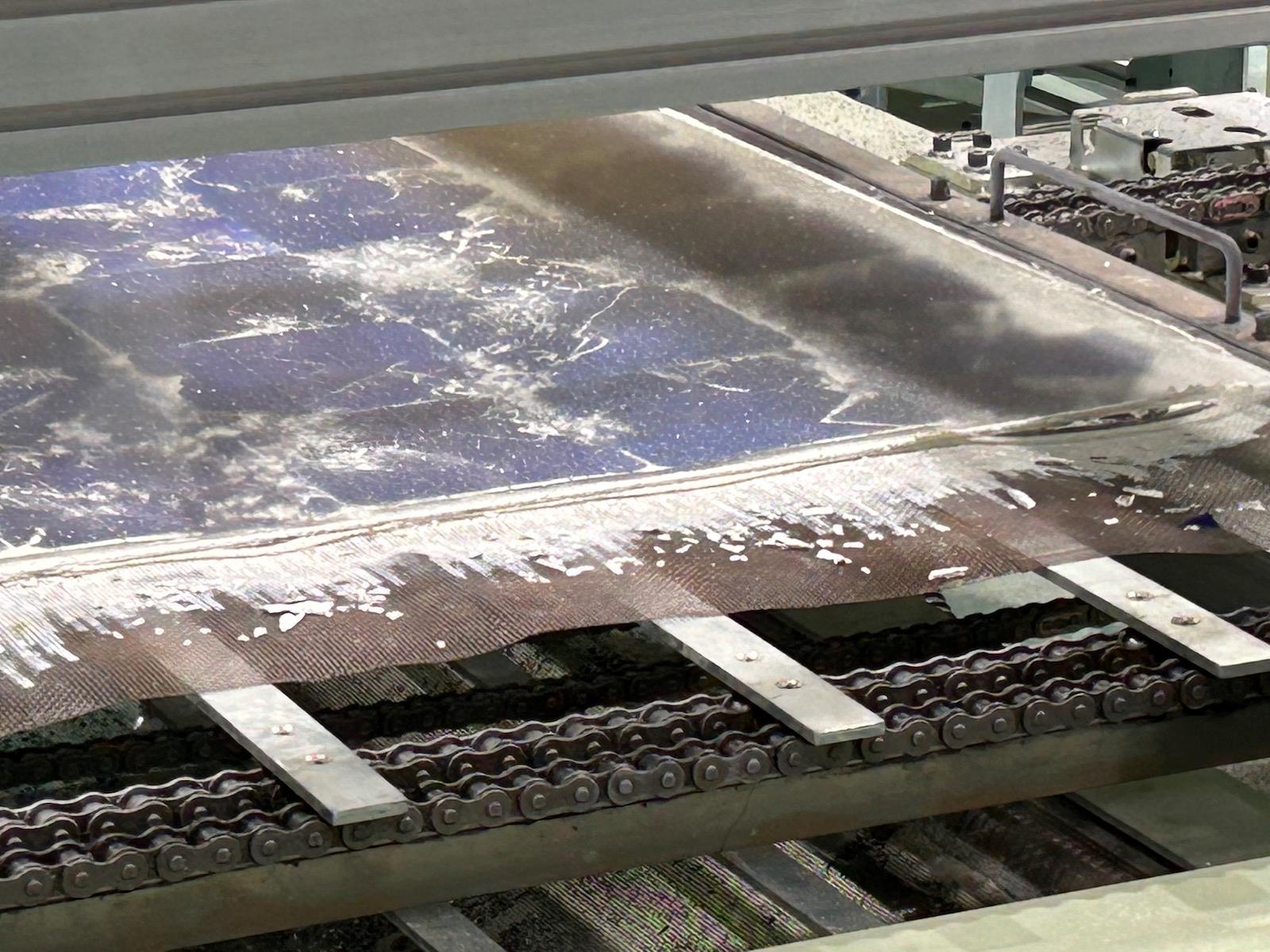

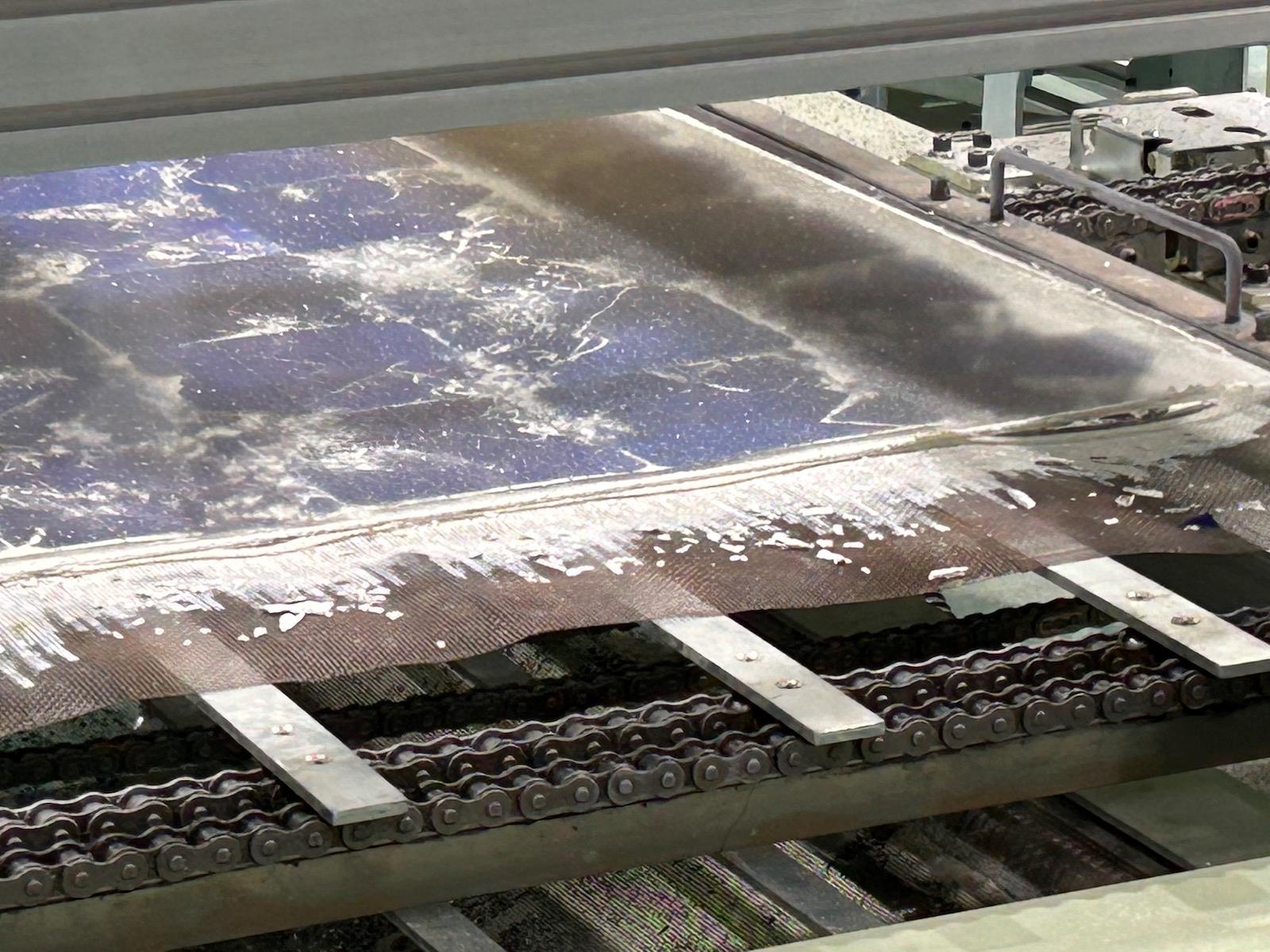

Another project aimed at effectively disposing of potential pollutants is currently being operated by Tokuyama Corporation in Nanporo, just east of Sapporo. The project is the development of advanced technology that can recycle photovoltaic (PVC) panels used to generate solar power.

Because the panels are composites of various materials bonded together, they are particularly difficult to recycle. But setting the difficulty aside, with a number of early PVC panels expected to reach their useable limits by around 2030, developing technology to harvest the materials in the panels becomes increasingly important.

Tokuyama has found that by putting the solar panels through low-temperature decomposition ovens after stripping off their easily-recyclable aluminum frames, the glass, resin, cells and ribbon components of the panels can be readily separated from one another so that they can be recycled and reused. Keeping the temperatures relatively low (between 300 and 450 degrees Celsius) while using ceramic filters has been particularly crucial to the process, which renders the resulting material nearly 100% recyclable.

Low-temperature ovens enable the separation of bonded materials in order to recycle PVC solar panels. Photo: Vickie L. Beyer

With such a variety of projects aimed at reducing the harmful effects of CO 2 , Hokkaido is well positioned to show off its green credentials to the G7 ministers and, more importantly, to achieve its carbon neutrality goals.

vicki l. beyer is a former professor of law in the Business Law Department of Tokyo's Hitotsubashi University Graduate School of Law. She continues to lecture on business law, corporate governance and employment law at various institutions. A lawyer admitted to practice in the US state of Washington who spent 17 years as an in-house lawyer with American multinationals, she is a regular commentator on Japanese business, law and society. She recently served as kanji (standing auditor) of the Foreign Correspondents' Club of Japan. Follow her on Twitter @JigsawVLBeyer

Like this:Like Loading...

Comments

No comment