Protection of nuclear power workers opens doors to Aussie innovators at electricity plants in US and globally

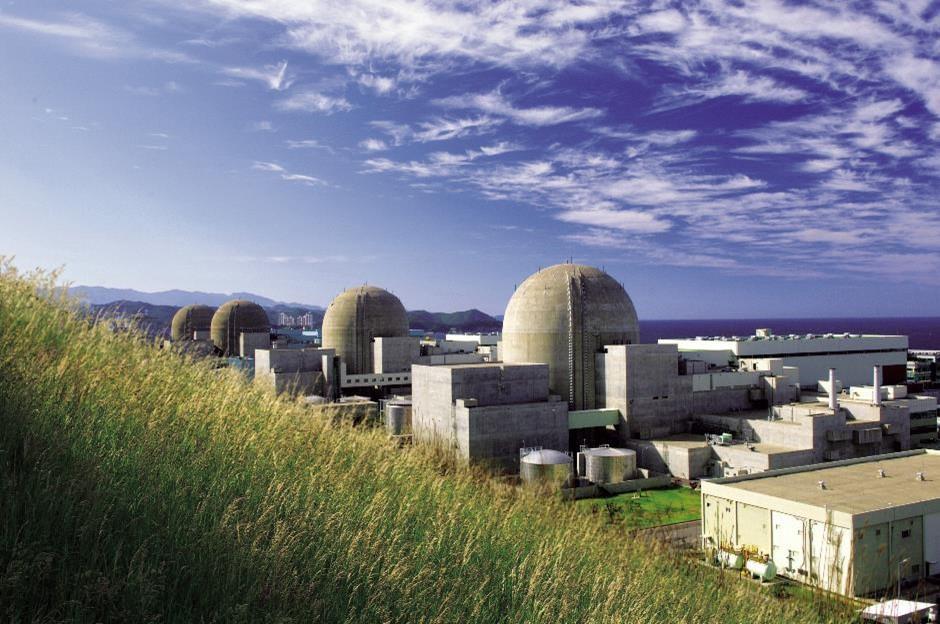

The Hanul power plant in South Korea, which uses an Australian Technofast CamNut® system not only to increase operational safety, but also to boost generation uptime

A circular series of CamNuts offering simultaneous tensioning and release of electricity generation plant

Normally, a bolt tensioning tool pulls on the bolt threads protruding above the regular hex nut, which is then screwed down to retain the loads induced by hydraulic operation of the tool. With no available thread, the CamNut (pictured) performs as the con

Technofast's fast-actuation, quick-release CamNut® system delivers time savings and safety gains for Korean fleet of nuclear power generation plants.

The time savings and safety gains proven in these installations apply to all power generation applications, including nuclear, fossil, hydro and green generation.” — John BucknellCRESTMEAD, QUEENSLAND, AUSTRALIA, November 25, 2021 /EINPresswire.com / -- Electricity generation uptime and safety gains at some of the world's largest nuclear power plants are winning international recognition for the fast-actuation, quick-release CamNut ® system from Australian precision engineering company, Technofast.The successful use of the system at the Hanul nuclear plant in South Korea – with an installed 6157MW capacity in two stages – has been complemented by their use also at the country's Wolsong, Shin Wolsong and Hanbit nuclear plants and at major steam turbine plants as well.

The ongoing work among the Korean fleet of nuclear power generation plants, which supply a third of ROK's electricity needs, has won Technofast accreditation as a supplier to the country's nuclear industry, having attained certification to design and manufacture equipment for this sector.

“Attaining certification from a world leader in terms of nuclear electricity generation opens the door to global applications for the CamNut and complementary EziTite ® systems in nuclear and electricity plants of all types,” says Technofast Founder and CEO, Mr John Bucknell.

“The time savings and safety gains proven in these installations apply to all power generation applications, including nuclear, fossil, hydro and green generation. They offer the same benefits to all industrial applications where workers need to ensure equipment uptime while avoiding exposure to hazardous situations, including radiation, heat, fuel, pressure and the need to work in confined workspaces where clumsier, time-consuming fastening tools are not recommended.”

The Technofast hydraulic CamNut system and complementary EziTite hydraulic bolts and specialist complementary products enable entire groups of fasteners to be torqued or released immediately and simultaneously, rather than laboriously being individually installed and released. An additional benefit of CamNuts® is that they can be used where thread length above the nut is insufficient to apply normal Bolt Tensioners, meaning users no longer need to replace expensive studs to gain the benefits of hydraulic direct tensioning. The unique stepped base washer provides a firm reaction point for tensioning without altering spotface diameters on turbine casings. Also, bolts are not subject to thermally induced stresses from rapid and uneven heating which is important for longevity, reliability, and safety.

Equipment decommissioning, maintenance and installation for regular service operations is typically cut by 60-80 per cent, carving days off the maintenance schedules of the Korean power station applications, says Mr Bucknell.

“This means big gains for every hour sooner that equipment can be brought back online to produce generating revenue. Days can mean millions of dollars in generation industries – and the CamNut and EziTite systems offer better risk management, by getting people in and out of machinery quicker which is a major plus in industries such as oil and gas, mining and energy, manufacturing and processing.”

The savings at the original Korean nuclear and fossil electricity applications have been proven over more than a decade, with multiple new applications following their success. The CamNut system and its complementary products are used in major areas of the Korean Nuclear generators including:

•Combined Reheat Valve (CRV) (CamNut – 1.75in)

•Main Stop Valve (MSV) (CamNut 2.5in)

•Control Valve (CV) (CamNut 3in)

•High-pressure control valve and stop valve (CamNut)

•Venturi (EziTite Hydraulic Nut 3in)

CamNuts are rapidly applied by being placed on bolt studs then hydraulically actuated, stretching the bolt to the precise tension required and then locking it in place mechanically with a locking device. The reverse procedure permits equally rapid disassembly when it is eventually required for annual or ad hoc maintenance, for example.

The fast and secure hydraulic fastening system uses hydraulic force to draw and release the bolt, rather than each fastener it being locked or loosened individually by operations staff using wrenches to torque the bolt by rotating it on the thread or using heat processes.

CamNuts' direct extension methods avoid thermal stress and heat deterioration of bolts. Applied onto existing fasteners, the CamNuts operate simultaneously to reduce downtime and extend the lifespans of metal no longer subjected to thermal stress caused by rapid uneven heating.

Besides eliminating safety hazards associated with more laborious maintenance methods, CamNut and EziTite fasteners optimise long-term safety by ensuring even tensioning across a range of bolts, where tensioning precision is vital to long-term performance. Extremely accurate and even loads on the flange/joint, enhance ongoing reliability of the machinery in service.

Benefits of using CamNuts with direct tension:

•Designs for extreme situations/adverse conditions.

•Improved safety, fast to fit and remove.

•Requires little physical effort, user friendly.

•Minimises cost.

•Reduces downtime, optimises profitable uptime.

•Allows the benefits of hydraulic tensioning without changing expensive bolts

•Increase bolt load accuracy

•Eliminate thread galling

•Increase the life of the hardware

•No hardware modifications

•Modular construction reduces overall tool weight.

•Achievable reliable and precise tensioning the first time.

•Reduce breakdowns and damage.

•Removes risk of strike and pinch point injuries caused by other tightening methods.

John Bucknell

Technofast

+61738036550 ext.

Visit us on social media:

LinkedIn

Technofast CamNut solution

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment