Parallel And Taper Threads In Instrument Connection

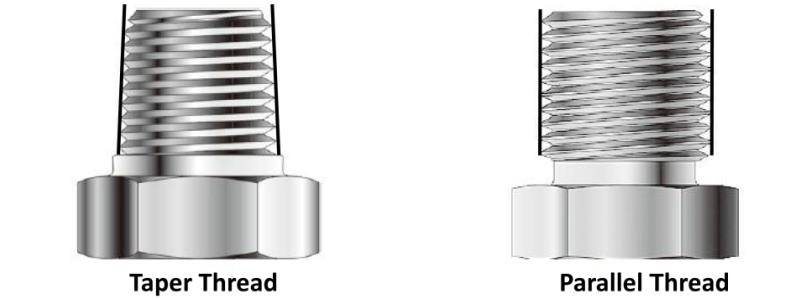

Threaded connections serve not only to hold components together but also to prevent media leakage. There are two primary thread types: parallel and taper threads. Each differs in geometry and sealing mechanism.

Parallel Thread

Also known as straight thread, parallel thread has a consistent diameter and thread profile along their entire length. This uniform shape simplifies alignment and installation. However, as the thread does not taper, it does not inherently create a seal through radial compression. Instead, it may depend on auxiliary sealing elements-such as O-ring, gasket, or washer-to prevent leakage in high pressure application. The main function of the thread is to provide mechanical strength. This design makes parallel thread well-suited for applications requiring frequent assembly and disassembly, since the replaceable seal simplify maintenance without damaging the thread.

Taper Thread

Taper thread is machined with a gradually reducing diameter, creating a conical form. As male and female components are engaged, the taper produces a wedging effect that increases thread contact and creates a mechanical interference fit. This radial compression forms a metal-to-metal seal, which becomes tighter under pressure, making taper thread highly effective in high-pressure or dynamic systems involving gases or liquids. The sealing performance of taper thread improves with tightening and pressure increase, eliminating the need for additional seals in many applications.

Selection Consideration

Parallel threads are often preferred in low-pressure systems or where modularity and ease of maintenance are prioritized. It is critical to select compatible gaskets or O-rings to ensure leak-tightness.

Taper threads excel in high-pressure environments, especially in hydraulic, pneumatic, or process fluid systems. Their self-sealing capability under pressure makes them a reliable choice under demanding conditions.

For instruments installation, common thread standards include Metric and BSPP (parallel), as well as NPT and BSPT (tapered). When selecting a connection type, it is essential to consider operating conditions, pressure levels, and compatibility with existing system interfaces. With over 20 years of experience in manufacturing measurement instruments, Shanghai Wangyuan offers a wide range of thread options for transmitters and supports custom configurations for process connection. Please feel free to contact us for further inquiry or specific requirements.

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment