GMG Announces Graphene Coating Patent Approval And Customer Case Study Successes

| Work Description | Before Coating Temp. °C / °F | After THERMAL-XR® Coating Temp. °C / °F | Difference due to THERMAL-XR® °C / °F |

| Entry to Cooling Coil | 25.4 / 77.7 | 25.2 / 77.4 | |

| Exit from Cooling Coil | 17.5 / 63.5 | 16.4 / 61.5 | |

| Temp. Reduction Provided by Cooling Coil | 7.9 / 13.5 | 8.7 / 15.9 | 1.2 / 2.4 (10.6%) |

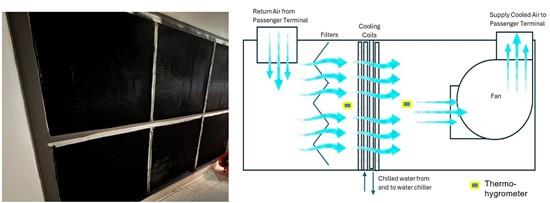

The air flow pressure across these internal cooling coils was recorded before washing, after washing and then after coating with THERMAL-XR® ENHANCE. The recordings show a notable 6.5% reduction of air flow pressure due to the significant reduction in friction caused by the graphene coating.

| Work Description | Air Pressure at Entry to Cooling Coil (Pascal) | Air Pressure at Exit from Cooling Coil (Pascal) | Difference in Air Pressure between Entry & Exit of Cooling Coil |

| Washing & Cleaning | 287 | 268 | 19 (6.6%) |

| THERMAL-XR® Coating | 275 | 257 | 18 (6.5%) |

| Washing & Cleaning + THERMAL-XR® Coating | 287 | 257 | 30 (10.5%) |

GMG's Managing Director and CEO, Craig Nicol, commented: "Our partnership with our distributors continues to be quite successful and we look forward to implementing more energy savings projects with THERMAL-XR® Powered by GMG Graphene with various other companies and around the world."

About GMG:

GMG is an Australian based clean-technology company which develops, makes and sells energy saving and energy storage solutions, enabled by graphene manufactured via in house production process. GMG uses its own proprietary production process to decompose natural gas (i.e. methane) into its natural elements, carbon (as graphene), hydrogen and some residual hydrocarbon gases. This process produces high quality, low cost, scalable, 'tuneable' and low/no contaminant graphene suitable for use in clean-technology and other applications.

The Company's present focus is to de-risk and develop commercial scale-up capabilities, and secure market applications. In the energy savings segment, GMG has initially focused on graphene enhanced heating, ventilation and air conditioning ("HVAC-R") coating (or energy-saving coating) which is now being marketed into other applications including electronic heat sinks, industrial process plants and data centres. Another product GMG has developed is the graphene lubricant additive focused on saving liquid fuels initially for diesel engines.

In the energy storage segment, GMG and the University of Queensland are working collaboratively with financial support from the Australian Government to progress R&D and commercialization of graphene aluminium-ion batteries ("G+AI Batteries"). GMG has also developed a graphene additive slurry that is aimed to improve the performance of lithium-ion batteries.

GMG's 4 critical business objectives are:

Produce Graphene and improve/scale cell production processes Build Revenue from Energy Savings Products Develop Next-Generation Battery Develop Supply Chain, Partners & Project Execution Capability

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment