Thomson Adds Advanced Synchronisation Control To Electrak HD Linear Actuators

June 18, 2025 by Sam Francis

Thomson Industries , a manufacturer of linear motion control solutions, has introduced an“enhanced synchronisation” option for its Electrak HD smart electric linear actuator.

The new iteration of this control option implements position-based synchronisation within the actuators' onboard electronics for modern motion control applications requiring instant load balancing of multiple Electrak HD units.

Anders Karlsson, senior product manager – linear actuators at Thomson, says:“We worked closely with industrial equipment builders who need dynamic and reliable load synchronisation and redesigned our controls to meet their demands.

“By incorporating advanced position sensing and communication capabilities, we have streamlined the process of synchronising multiple actuators. This enhancement helps users achieve increased efficiency, strength and safety in heavy duty applications.”

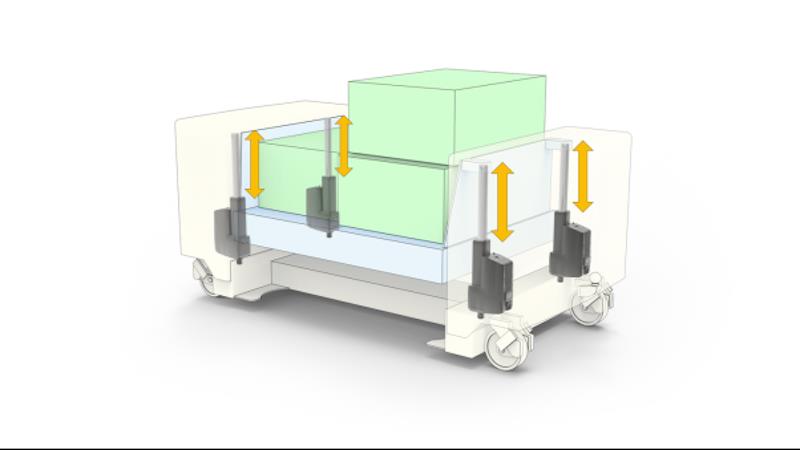

Actuators in lockstepThe synchronisation option can support up to eight Electrak HD actuators that connect in real time across a CAN bus network, ensuring operation in perfect harmony. A constant heartbeat signal in each actuator maintains position awareness for all units.

If one actuator senses a heavier load, it will signal to the others to slow their speed to maintain the same position.

Only in the instance of a fault (loss of communication or power, or excessive voltage or temperature) on one or more of the actuators will the entire system shut down. This instant communication prevents binding or buckling, enhancing reliability and safety.

Unlike most other position-based actuators, which require space-consuming external controls, the Electrak HD embeds all synchronisation functionality into its built-in electronics, making the system truly plug and play.

All mounted and wired actuators can begin synchronising immediately following installation.

The Electrak HD can handle dynamic loads of up to 16 kN, making it a popular choice for applications where hydraulic cylinders were traditionally used.

Its improved synchronisation capabilities make the HD particularly suitable for systems that require dynamic load balancing and position control – features that are not achievable with conventional hydraulic cylinders.

The synchronising option is beneficial for many applications that are challenged with awkward or unbalanced loads, including:

-

Work platforms, where the system must maintain a level surface as workers change position.

Automated material handling, where multiple actuators help move products smoothly along conveyor belts or on an automated guided vehicle.

Packaging automation, where multiple actuators position items and stack products.

Solar panels, where multiple actuators help raise, lower and tilt heavy loads in sync and protect them from structural damage.

The enhanced synchronisation option is available immediately when ordering the Thomson Electrak HD.

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment