Bodor Laser Provides All-In-One Profile Cutting Solution For Structural Steel Fabrication

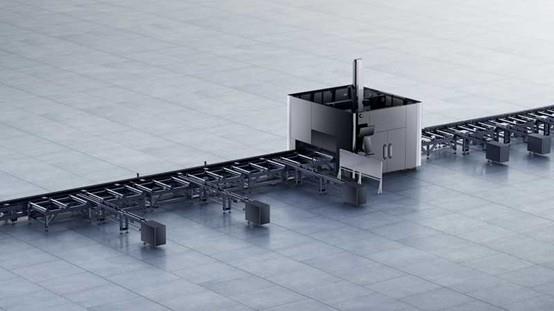

Bodor Hicut Professional Profile Fiber Laser Cutting Machine

Conventional I- and H-beam workflows are complex and prone to positioning errors, especially with intricate patterns. Bodor's solution unifies hole-making, beveling, notching, marking, and cutting into one automated cycle supporting continuous cutting, loading, and unloading. With Tekla® integration and Intelligent Deviation-Correction Positioning, the system reproduces design details with high accuracy, ensuring smooth on-site assembly.

1. U3000 Professional Multi-task Fiber Laser Cutting Machine

The U3000 processes profiles, sheets, and tubes within a single machine. With a maximum processing length of 110.24 inches, multiple worktables can be added for uninterrupted loading, cutting, and unloading.

Key functions:

- Profile cutting for standard and irregular structural steel Sheet cutting for holes, straight cuts, and bevels Tube cutting for hole-making, beveling, intersection and through-cuts Optional steel base for flexible installation

2. Hicut Professional Profile Fiber Laser Cutting Machine

Engineered for automated I-beam and H-beam fabrication, the Hicut integrates loading, hole-making, notching, beveling, cutting, and unloading without manual intervention.

Highlights:

- Rapid loading (<20 seconds) with intelligent zoning that groups workpieces by length One-pass lock notching with optimal standoff; no secondary grinding required Five-axis linkage and 180° reciprocating laser-head movement enabling full-angle, high-precision cuts

Both machines are deployed by structural-steel manufacturers across North America for infrastructure, machinery, and shipbuilding applications. Their performance and responsive service have earned strong customer recognition.

As of 2024, Bodor has led global fiber-laser sales for six consecutive years(Shenzhen Forward Research Institute, Sales Records of Laser Cutting Machines with 1000W and Above from 2019 to 2024, Consecutively for Six Years). Its core components-Bodor Laser (laser source), Bodor Thinker (control system), and Bodor Genius (cutting head)-carry a five-year warranty. In North America, Bodor continues expanding its service team and strengthening local spare-parts inventory to support manufacturers. A Bodor representative noted that the company will keep advancing laser-processing technology while reinforcing its service network to better meet regional demand.

A photo accompanying this announcement is available at

CONTACT: Contacts Dennis Wang... Bodor Laser Inc.

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment