Dubai: 4 Students Collect Waste, Turn 500 Plastic Bottles Into 3D Printing Filament

In a world drowning in plastic waste, four engineering students from a university in Dubai have found a way to turn one of the planet's biggest environmental challenges into a practical, small-scale solution-one that could be replicated in classrooms and labs across the UAE.

The students have successfully transformed used water bottles into filament suitable for 3D printing, offering sustainable solutions.

Recommended For You Dh1 items to 90% discount: UAE's Black, White, Yellow, Green Friday Sales explainedThe project was spearheaded by mechanical engineering students Reem Aly, Shriya Vijay, Vishnu Shyju, and Muhammed Sharfuddin from the Rochester Institute of Technology (RIT) Dubai. Their work was supervised by Dr Wael A. Samad, Chair of the Department of Mechanical and Industrial Engineering.

Stay up to date with the latest news. Follow KT on WhatsApp Channels.

The initiative formed part of the team's graduation work and built on previous sustainability-focused research at the university, including RIT Dubai's 2023–24 DEWA Al Baheth grant for 3D printing innovation.

From waste to something valuable

Speaking to Khaleej Times, Egyptian national Reem Aly, a Chemical Engineering student now interning at the DEWA R&D Centre's 3D Printing Department, described how the idea took shape.

“We were a team of four. At RIT Dubai, we asked: What if we could turn this waste into something valuable? Instead of tossing bottles after a single use, we set out to transform them into high-quality 3D printing filament. Our goal? To reduce plastic waste while creating a cost-effective and sustainable alternative to commercial filaments like PLA and PETG,” she said.

The team had already experimented with recycling other waste plastics in 2024, successfully producing filament that could be used again for 3D printing. But when their instructor proposed shifting the focus specifically to PET water bottles, the students realised they could design a process simple enough for“schools, universities and other small institutions” to replicate.

“This wasn't done before,” Reem noted.“Our goal was to basically design a process for recycling plastic bottles into filament for 3D printing in a way that it can be replicated for other academic labs with just desktop-size machines.”

Collecting campus waste

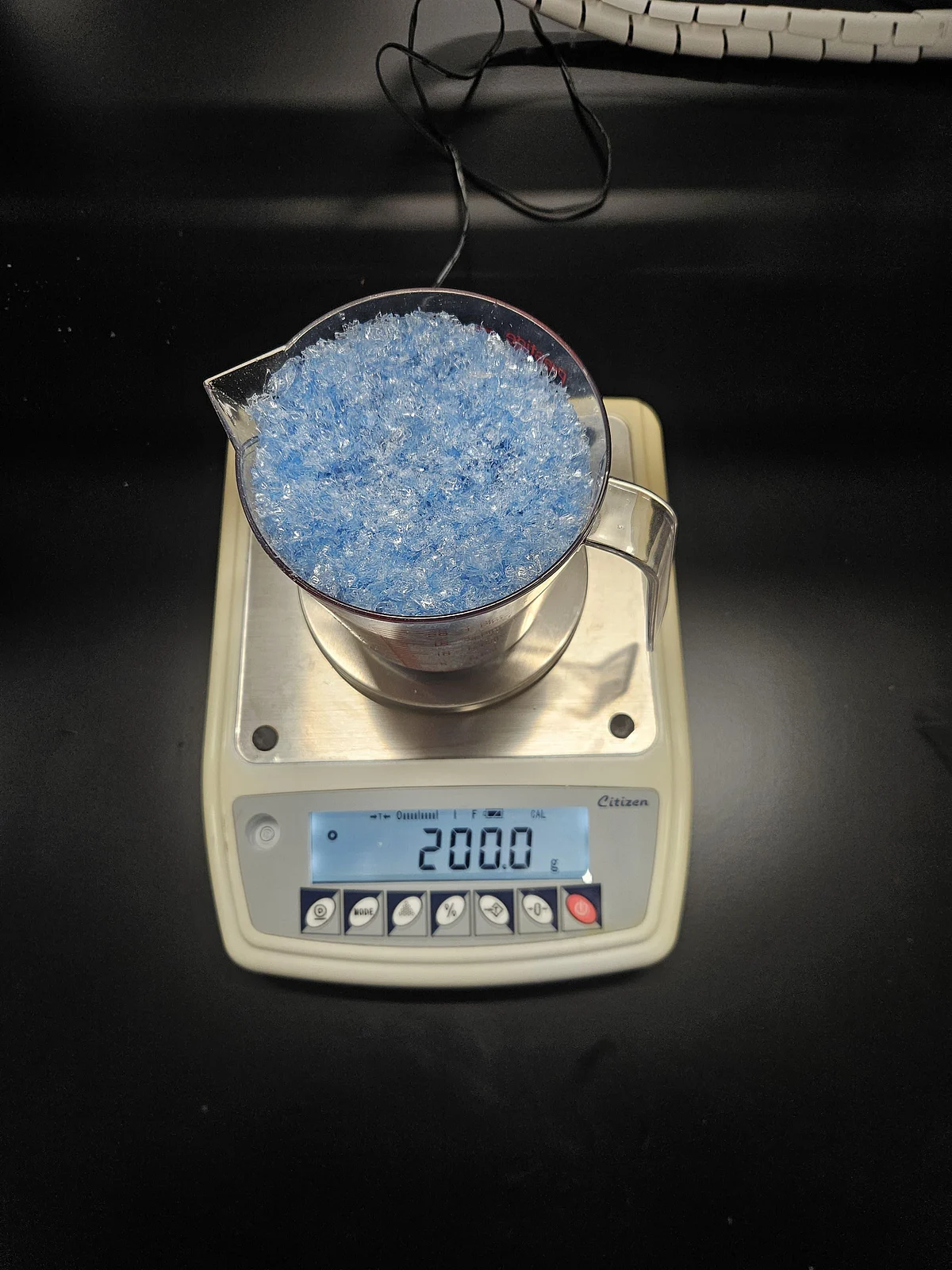

The team collected 500 bottles-both 1.5-litre and 500ml-from around campus, including their own and those gathered by friends. Every bottle was washed, dried, stripped of caps, labels and rings, and then shredded into PET flakes.

Reem walked us through the process with precision, as she and her team members spent eight months from ideation to execution.

“We dried the flakes to completely remove any moisture,” she said.“We basically needed to dehydrate it to avoid thermal degradation that could happen when we exposed it to heat... After putting it in the oven for five hours at 150–160 degrees, we took the shreds and put it in our filament extruder.”

The machine then heated and blended the flakes before pushing out a continuous strand of filament. The team regulated it to 1.75mm, the standard diameter for desktop FDM (Fused Deposition Modelling) 3D printers, and then spooled the finished filament.

“Twelve plastic bottles of 1.5 litres were converted into 200g of flakes which created 30m of spool,” Reem explained.“With 3D printing you can print whatever you like. For future work we need to research more to enhance it for better applications.”

Meeting engineering challenges head-on

Dr Samad emphasised that the project required navigating the complexities of working with PET, a material widely used for beverage packaging but notoriously difficult to process.

“Processing PET is far from straightforward as it has specific characteristics that create a very narrow processing window,” he noted.“Despite these engineering difficulties, the team optimised processing and print parameters and benchmarked their recycled PET against commercially available filaments in the market.”

The results form the basis of a research paper titled Sustainable Filament Production: Recycling Plastic Water Bottles into High-Quality 3D Printing Filaments, which is currently being prepared for publication.

“Recycled PET filaments do come with trade-offs compared to commercial filaments, but they also offer unique advantages,” Dr Samad added.“This project has demonstrated that 3D-printed parts made from recycled PET possess properties that make them a promising choice for applications where sustainability is a priority, particularly in prototyping and low-load bearing applications.”

Small step with national significance

With an estimated 500 billion plastic bottles used globally each year-over a million every minute-the students' work represents a small but meaningful contribution to the fight against plastic pollution. At the local level, it echoes the UAE's wider sustainability ambitions, including the UAE Green Agenda 2030.

For Dr Samad, the project's true value lies not only in its scientific outcomes but in the mindset it fosters.

“What I find most exciting is seeing our students use rigorous engineering methods to transform waste into opportunity,” he said.“Projects like this not only prepare them to tackle global challenges but also align closely with the UAE's drive toward sustainability and innovation.”

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment