Allied Critical Metals Expands Santa Helena Breccia In Borralha With Long Tungsten Intercepts And Confirms High-Grade Trend

| Drill Hole ID | Coordinates (WGS84) | Az.(o) | Dip.(o) | PFD (m) | DEPTH (m) | |

| Bo_RC_14/25 | 585445 | 4611405 | 109 | 80 | 250 | 264.00 |

| Bo_RC_15/25 | 585347 | 4611368 | 109 | 70 | 300 | 255.00 |

| Bo_RC_16/25 | 585406 | 4611329 | 105 | 60 | 240 | 251.00 |

| Bo_RC_17/25 | 585426 | 4611295 | 109 | 75 | 250 | 255.00 |

| Bo_RC_18/25 | 585461 | 4611431 | 109 | 75 | 300 | 241.00 |

| Bo_RC_19/25 | 585470 | 4611493 | 109 | 82 | 350 | 247.00 |

| Bo_RC_21/25 | 585484 | 4611552 | 109 | 85 | 400 | 370.00 |

| Bo_RC_22/25 | 585484 | 4611552 | 109 | 70 | 360 | 375.00 |

| Bo_RC_26/25 | 585586 | 4611449 | 289 | 60 | 400 | 287.00 |

Table 2 - Drill Hole Interval Highlights

| Drill Hole ID | From (m) | To (m) | DH length (m) [1] | True factor [1] | True Width (m) [1] | WO 3 (%) |

| Bo_RC_14/25 | 52.0 | 64.0 | 12.0 | tbd [2] | - [2] | 4.27 |

| incl. | 52.0 | 58.0 | 6.0 | tbd [2] | - [2] | 8.39 |

| Bo_RC_15/25 | 164.0 | 166.0 | 2.0 | 0.88 | 1.8 | 0.97 |

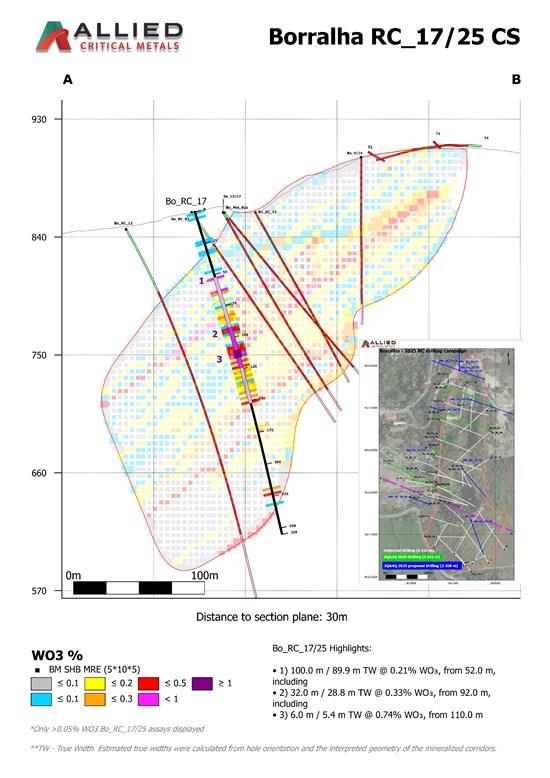

| Bo_RC_17/25 | 52.0 | 152.0 | 100.0 | 0.90 | 89.9 | 0.21 |

| incl. | 92.0 | 124.0 | 32.0 | 0.90 | 28.8 | 0.33 |

| incl. | 106.0 | 120.0 | 14.0 | 0.90 | 12.6 | 0.52 |

| incl. | 110.0 | 116.0 | 6.0 | 0.90 | 5.4 | 0.74 |

| Bo_RC_22/25 | 284.0 | 348.0 | 64.0 | tbd [2] | - [2] | 0.12 |

| incl. | 316.0 | 332.0 | 16.0 | tbd [2] | - [2] | 0.21 |

Notes: [1] Reported intervals are downhole lengths. Estimated true widths were calculated from hole orientation and the interpreted geometry of the mineralized corridors. Estimates may vary locally where geometry changes. Where intervals fall outside the resource block-model domains, true widths are not estimated and only downhole lengths are reported. [2] True widths are unknown.

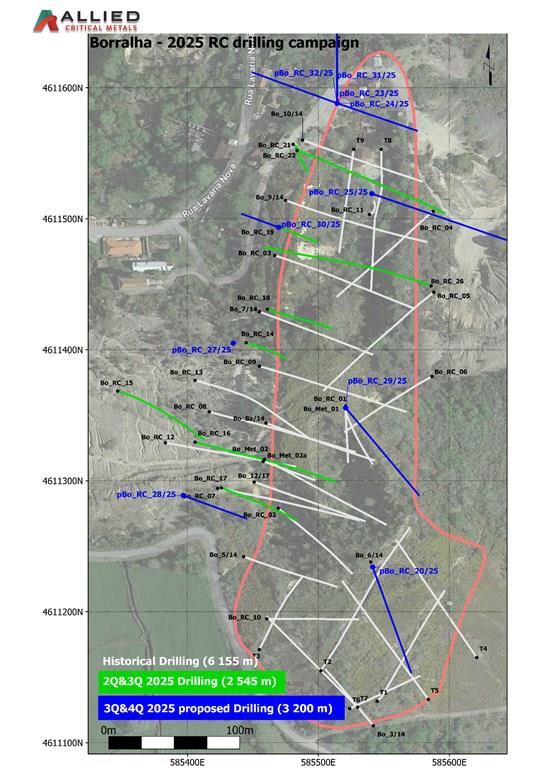

Figure 1 – Drill collar plan showing planned holes for the ongoing 5,728 m RC campaign at the Borralha Project. The red outline delineates the main mineralized breccia zone.

To view an enhanced version of this graphic, please visit:

Figure 2 – Geological Cross-Section for hole Bo_RC_17/25 .

To view an enhanced version of this graphic, please visit:

Geologic Interpretation

The geologic interpretation indicates that the Santa Helena Breccia is expanding: the combination of broad medium-grade intervals and discrete high-grade intercepts points to a larger, better-connected breccia body than previously modeled. Priority vectors for follow-up include the west-dip high-grade trend (Bo_RC_14/25 and Bo_RC_15/25) and the northern wider deep lode (Bo_RC_22/25), which will guide near-term drilling and feed the Q4 2025 MRE and subsequent PEA workstreams.

Next steps

Ongoing drilling continues to target west-deep and northern extensions while tightening spacing across the MRE backbone. Additional assays from completed holes will be released as received and validated. The program remains aligned with the timeline toward an updated MRE (Q4 2025) and PEA thereafter.

Technical Information and Quality Assurance/Quality Control (QA/QC)

Drilling was completed using reverse-circulation (RC). All sample bags were pre-labelled with a unique internal sequence number used consistently for the assay sample and corresponding reject. Sampling was conducted on 2.0 m intervals for analytics. For each 2.0 m interval, two 1.0 m reject samples were also collected as representative splits. Splitting was performed at the rig via a rotary splitter integral to the RC cyclone.

Sampling followed pre-prepared sample lists that recorded downhole metreage, sequence, and the placement of Certified Reference Materials (CRMs) and field duplicates. CRMs were inserted at a rate of 1 in 20 samples (5%) and field duplicates at 1 in 20 samples (5%), arranged so that every 10th sample alternated between a CRM and a duplicate.

Analytical and reject samples were boxed at the drill site and transported by company personnel to the project core/logging facility. Analytical samples were stored on labelled pallets pending direct shipment to ALS's preparation laboratory in Seville, Spain. Pulps and rejects were subsequently stored securely in the project logging room.

At ALS Seville, samples were crushed to 70% passing 2 mm, riffle-split to ~250 g, and pulverized using hardened steel to 85% passing 75 μm. Pulps were shipped to ALS Loughrea (Ireland) for analysis. The primary analytical method was ME-MS81 (lithium borate fusion with ICP-MS finish). Base metals were also reported using ME-4ACD81 (four-acid digestion with ICP-MS finish). Over-limit tungsten results were re-assayed using W-XRF15b (lithium borate fusion with XRF). Analytical results were delivered directly by ALS to the Company via secure electronic transfer.

To the best of the Company's knowledge, no drilling, sampling, recovery, or other factors have been identified that would materially affect the accuracy or reliability of the data referenced herein.

Where reported, metal factor (m·%WO3) is the product of interval length and grade and is provided as supplemental context only. Primary disclosure remains the reported grade and interval length (and true width where known).

Qualified Person

The scientific and technical information in this news release has been reviewed and approved by Mr. Vítor Arezes, BSc, MIMMM (QMR) (Membership No. 703197, Vice-President Exploration of Allied Critical Metals, who is a Qualified Person for the purposes of National Instrument 43-101 – Standards of Disclosure for Mineral Projects. Mr. Arezes is not independent of Allied Critical Metals Inc. as he is an officer of the Company.

Understanding Tungsten

To understand tungsten, it is critical to understand the difference between wolframite tungsten mineralization and scheelite tungsten mineralization. Scheelite often reports higher grades (0.3%-1.0% WO3) but is more costly and complex to process, requiring flotation methods with higher capital and operating expenditures and lower recoveries.i In contrast, wolframite, which is the focus of Allied, can be processed more efficiently using gravity and magnetic separation, resulting in lower costs and higher recoveries, making lower grades (~0.15%-0.25% WO3) economically viable in wolframite deposits. For example, a wolframite deposit with 0.4% WO3 over 3 metres can be more profitable than a scheelite deposit with 0.7% WO3 over the same interval due to lower processing costs and higher recovery rates.ii

In Western exploration drilling, tungsten grades typically range from 0.3% to 1.0% WO3.iii The cut-off grade for economic viability is generally around 0.1% WO3, with highly efficient operations able to mine at grades as low as 0.08% WO3. Skarn deposits, a common deposit type, typically range from 0.34% to 1.4% WO3, with intercepts of 0.4% WO3 over 1-5 metres considered very good and 0.7% WO3 over 1-3 metres considered very high-grade.iv Intercept lengths can range from 0.6 metres to over 100 metres, with longer intercepts at strong grades generally preferred for economic mining.

Published exploration results in Western jurisdictions demonstrate the standards for wolframite, with reported intercepts such as ~9-15 m @ 0.6-0.8% WO3, ~18 m @ 1.0% WO3, and typical intervals of 1-5 m @ 0.25-0.5% WO3. A result like 0.5% WO3 over 3 metres is generally considered strong within Western tungsten exploration benchmarks, especially for wolframite tungsten mineralization.v

It is also important to recognize that China, Russia, and North Korea control approximately 87% of the world's tungsten supply, using cheap labor and minimal environmental standards in authoritarian regimes. vi As a result, production costs and grades in these countries are not comparable to Western projects, which operate under higher labor, ESG, and energy cost structures. Evaluating projects outside these regions provides a realistic benchmark for what grades and intercepts are economically viable while supporting secure, NATO-aligned supply chains.

For Allied, this context is significant. Wolframite tungsten grades, ranging from 0.2% to 1.0% WO3 are strong global wolframite benchmark values. The Company's focus on wolframite ensures lower processing costs and higher recoveries, supporting project economics even at lower grades. Allied's operations in secure jurisdictions align with Western critical mineral needs, avoiding geopolitical risks associated with China and Russia while positioning the Company to benefit from growing tungsten demand across defense, aerospace, and electrification sectors. Allied's strong grades, low-cost processing advantages, and secure location position it as a strategic and responsible tungsten exploration company, well placed to support robust project economics in a rising-demand market. vii

* The results and intercepts referenced are drawn from publicly available disclosures of third-party mineral projects and are presented for industry benchmarking and comparison purposes only. Allied has no interests in those projects or entities.

ON BEHALF OF THE BOARD OF DIRECTORS,

"Roy Bonnell"

Roy Bonnell, CEO and Director

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Most popular stories

Market Research

- Japan Buy Now Pay Later Market Size To Surpass USD 145.5 Billion By 2033 CAGR Of 22.23%

- BTCC Summer Festival 2025 Unites Japan's Web3 Community

- GCL Subsidiary, 2Game Digital, Partners With Kucoin Pay To Accept Secure Crypto Payments In Real Time

- Smart Indoor Gardens Market Growth: Size, Trends, And Forecast 20252033

- Nutritional Bar Market Size To Expand At A CAGR Of 3.5% During 2025-2033

- Pluscapital Advisor Empowers Traders To Master Global Markets Around The Clock

Comments

No comment