Chlor-Alkali Production Cost Analysis Report 2025: Feasibility Study And Profit Analysis

Setting up a chlor-alkali production plant requires careful consideration of technology selection, raw material availability, and environmental compliance. Key factors include proximity to salt and water sources, reliable electricity supply, adherence to safety standards, and integration of waste treatment systems. A well-planned facility balances operational efficiency with sustainability, ensuring competitiveness in the chemical sector.

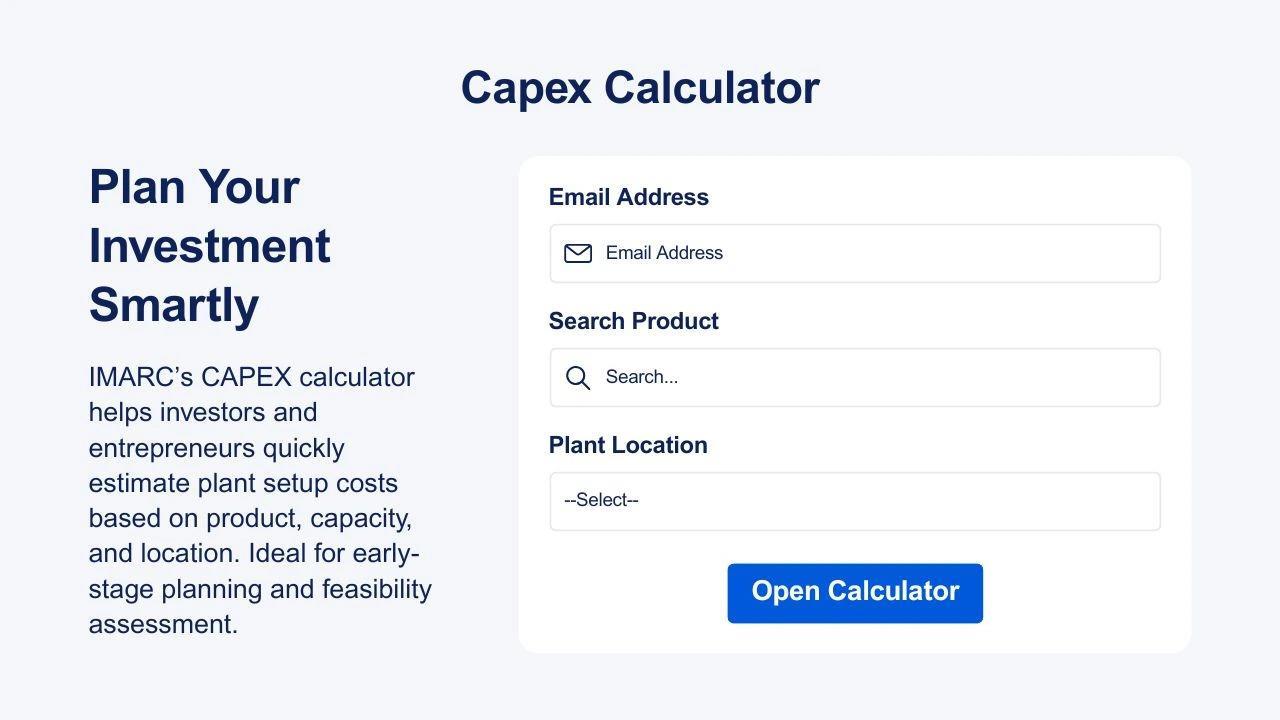

IMARC Group's “Chlor-Alkali Production Cost Analysis Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” offers a detailed and practical guide for entrepreneurs and businesses looking to enter the production industry. The report includes in-depth analysis of capital investment requirements, project financing options, working capital needs, and projected returns.

This comprehensive business plan outlines every critical step involved in setting up a successful production plant unit from understanding the industry landscape to planning for real-world challenges. It provides valuable insights into essential components such as chlor-alkali production plant cost, machinery cost, operating cost, raw material requirements, utility needs, infrastructure setup, and packaging logistics.

Request for a Sample Report : https://www.imarcgroup.com/chlor-alkali-manufacturing-plant-project-report/requestsample

Chlor-Alkali Industry Outlook 2025:

The chlor-alkali industry outlook for 2025 indicates steady growth driven by rising demand for chlorine in PVC production, caustic soda in alumina refining, and hydrogen in clean energy applications. Market expansion is supported by industrialization in Asia-Pacific and infrastructure development in emerging economies. Increasing adoption of membrane cell technology is expected to enhance energy efficiency and environmental compliance. However, volatility in raw material and energy prices, along with stringent environmental regulations, may pose challenges. Overall, the industry is positioned for moderate but sustainable growth, with innovation and eco-friendly practices shaping its competitive landscape.

Key Insights for Chlor-Alkali Production Plant Setup:

Detailed Process Flow:

-

Product Overview

Unit Operations Involved

Mass Balance and Raw Material Requirements

Quality Assurance Criteria

Technical Tests

Project Details, Requirements and Costs Involved:

-

Land, Location and Site Development

Plant Layout

Machinery Requirements and Costs

Raw Material Requirements and Costs

Packaging Requirements and Costs

Transportation Requirements and Costs

Utility Requirements and Costs

Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

-

Capital Investments

Operating Costs

Expenditure Projections

Revenue Projections

Taxation and Depreciation

Profit Projections

Financial Analysis

Profitability Analysis:

-

Total Income

Total Expenditure

Gross Profit

Gross Margin

Net Profit

Net Margin

Key Drivers of Chlor-Alkali Market Trends:

-

Growing PVC Demand – Rising use of chlorine in polyvinyl chloride (PVC) production for construction, packaging, and automotive industries.

Expansion of Alumina Industry – Increased consumption of caustic soda in alumina refining for the aluminum sector.

Water Treatment Needs – Higher demand for chlorine in municipal and industrial water purification and sanitation.

Industrialization in Emerging Economies – Rapid growth in Asia-Pacific and Middle Eastern markets driving chemical consumption.

Shift Toward Clean Energy – Hydrogen, a byproduct of chlor-alkali production, gaining importance as a clean fuel source.

Technological Advancements – Adoption of energy-efficient membrane cell technology improving cost-effectiveness and sustainability.

Environmental Regulations – Stricter policies phasing out mercury-based processes and promoting eco-friendly operations.

Key Cost Components of Setting Up a Chlor-alkali Plant :

-

Capital Investment – Land acquisition, plant construction, and infrastructure development.

Electrolyzer Technology – Cost of membrane, diaphragm, or mercury cell systems.

Raw Materials – Brine (salt), purified water, and chemicals for process operations.

Energy Requirements – High electricity consumption for electrolysis operations.

Utility Systems – Cooling water, steam, compressed air, and waste treatment facilities.

Environmental Compliance – Pollution control systems, effluent treatment, and safety measures.

Labor and Staffing – Skilled workforce for operations, maintenance, and safety management.

Logistics and Distribution – Storage, packaging, and transportation of chlorine, caustic soda, and hydrogen.

Economic Trends Influencing Chlor-Alkali Plant Setup Costs 2025 :

-

Energy Price Volatility – Electricity remains the largest operating cost, with fluctuating global energy prices directly impacting overall expenses.

Raw Material Availability – Shifts in global salt supply chains and brine quality affect procurement and processing costs.

Inflationary Pressures – Rising construction, equipment, and labor costs increase capital expenditure for new facilities.

Technological Advancements – Wider adoption of energy-efficient membrane cell technology can reduce long-term operating costs despite higher upfront investment.

Environmental Regulations – Stricter sustainability standards require additional investment in emission control and waste management systems.

Regional Industrial Demand – Expanding demand for PVC, alumina, and water treatment chemicals influences plant location and scale economics.

Request for Customized Report: https://www.imarcgroup.com/request?type=report&id=23602&flag=E

Challenges and Considerations for Investors in Chlor-Alkali Plant Projects:

-

High Capital Intensity – Significant upfront investment is required for land, electrolysis technology, and infrastructure.

Energy Dependency – Electricity accounts for a major share of operating costs, making plants highly sensitive to energy price fluctuations.

Environmental Compliance – Strict regulations on chlorine handling, effluent discharge, and emissions demand costly mitigation measures.

Market Volatility – Demand for caustic soda and chlorine is cyclical, tied to construction, alumina, and chemical industries.

Technology Selection – Choosing between membrane, diaphragm, or mercury cell technology impacts efficiency, costs, and sustainability.

Safety Risks – Handling hazardous products like chlorine requires robust safety systems and skilled personnel.

Supply Chain Factors – Reliable access to salt, water, and distribution networks is essential for uninterrupted operations.

Conclusion:

The chlor-alkali industry remains a cornerstone of the global chemical sector, supplying essential products such as chlorine, caustic soda, and hydrogen to diverse downstream industries. Establishing a new plant in 2025 requires careful evaluation of cost structures, technology choices, energy dependencies, and regulatory compliance. While high capital intensity and environmental obligations pose challenges, advancements in membrane cell technology and growing demand from sectors such as PVC, alumina, and water treatment present significant opportunities. Strategic planning, sustainability-focused investment, and efficient resource management will be critical for ensuring long-term competitiveness and profitability in chlor-alkali projects.

Buy Now : https://www.imarcgroup.com/checkout?id=23602&method=1911

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales[@]imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment