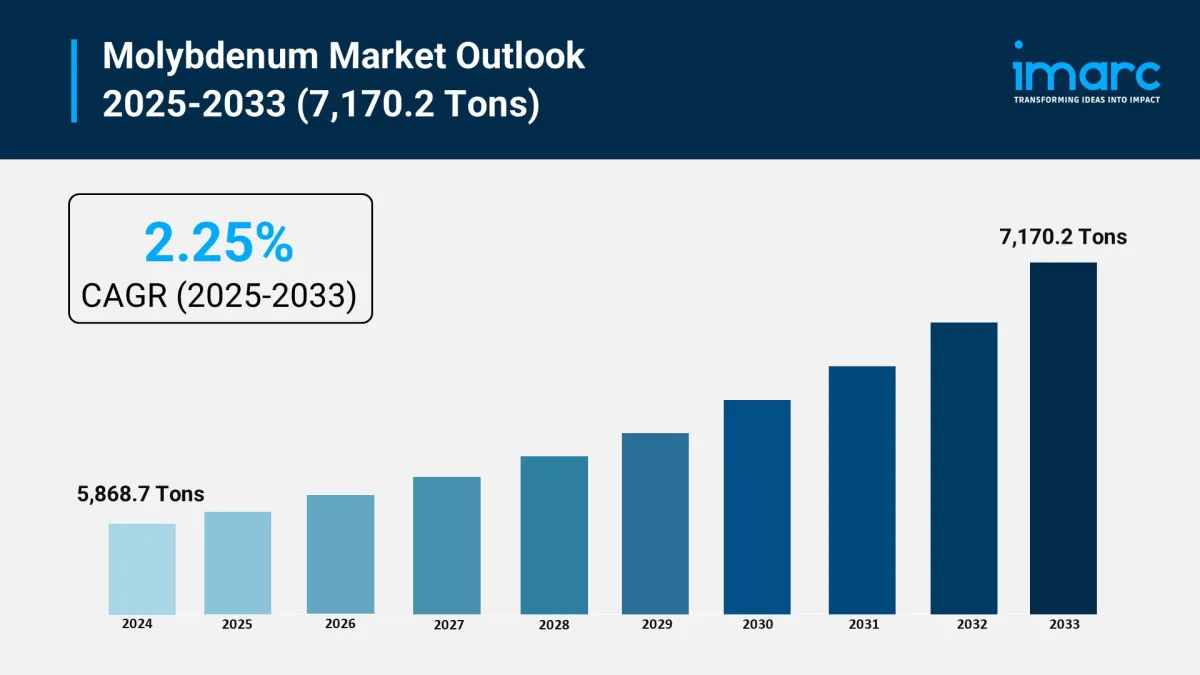

Molybdenum Market Size To Hit 7,170.2 Tons In 2033 Grow CAGR By 2.25%

The molybdenum market is experiencing rapid growth, driven by rising steel production and infrastructure demand, expansion in automotive and aerospace applications, and growth in renewable energy and clean technology. According to IMARC Group's latest research publication, “Molybdenum Market Size, Share, Trends and Forecast by Product Type, Sales Channel, End Use, and Region, 2025-2033, the global molybdenum market size was valued at 5,868.7 Tons in 2024. Looking forward, IMARC Group estimates the market to reach 7,170.2 Tons by 2033, exhibiting a CAGR of 2.25% from 2025-2033.

This detailed analysis primarily encompasses industry size, business trends, market share, key growth factors, and regional forecasts. The report offers a comprehensive overview and integrates research findings, market assessments, and data from different sources. It also includes pivotal market dynamics like drivers and challenges, while also highlighting growth opportunities, financial insights, technological improvements, emerging trends, and innovations. Besides this, the report provides regional market evaluation, along with a competitive landscape analysis.

Receive Your“Molybdenum Market” Sample PDF – Don't Miss Out!

Our report includes:

-

Market Dynamics

Market Trends and Market Outlook

Competitive Analysis

Industry Segmentation

Strategic Recommendations

Growth Factors in the Molybdenum Market

-

Rising Steel Production and Infrastructure Demand

One of the foremost drivers of molybdenum demand is its critical role in producing high-strength, corrosion-resistant steel alloys used extensively in construction and infrastructure projects. Molybdenum enhances steel's durability and weldability, making it indispensable for bridges, tunnels, and high-rise buildings. The steel segment accounts for the largest share of molybdenum consumption globally. For example, steel production in regions like Africa and the Middle East showed increases in millions of tons, fueling molybdenum use in industrial applications. This growing infrastructure development worldwide underpins steady consumption of molybdenum in steel manufacturing.

-

Expansion in Automotive and Aerospace Applications

Molybdenum's exceptional properties-strength, heat resistance, and corrosion protection-make it vital for automotive parts, aerospace components, and defense hardware. Automakers use molybdenum-containing high-strength low-alloy (HSLA) steel to reduce vehicle weight while improving performance and fuel efficiency. The aerospace sector relies on molybdenum alloys for components that must withstand extreme conditions. These industrial expansions contribute significantly to molybdenum demand, with companies investing heavily in advanced alloys for cutting-edge vehicles and aircraft.

-

Growth in Renewable Energy and Clean Technology

Molybdenum is increasingly important in the renewable energy sector, especially for manufacturing solar panels, wind turbines, and hydrogen fuel storage systems. Its high strength and corrosion resistance make it ideal for devices operating under demanding environments. Several government schemes globally are encouraging clean energy investments that emphasize molybdenum-intensive technologies. For instance, wind power projects in China anticipate requiring hundreds of thousands of tons of molybdenum. This clean technology push diversifies molybdenum's use beyond traditional industries, positioning it as essential for the energy transition.

Key Trends in the Molybdenum Market

-

Sustainable and Responsible Production Practices

The industry is witnessing a strong shift toward sustainability, with initiatives like The Copper Mark's pilot scheme for molybdenum producers. This framework promotes responsible mining practices through independent site assessments, addressing environmental impact and social responsibility. Companies increasingly adopt greener mining and processing techniques, driven by both regulatory pressure and consumer expectations for ethical sourcing. This trend enhances the transparency and sustainability credentials of molybdenum supply chains, strengthening market trust.

-

Technological Innovations: 3D Printing and Metal Powders

Molybdenum powder is gaining traction as a material for metal additive manufacturing (3D printing), enabling lightweight, high-strength parts for aerospace, defense, and automotive industries. The demand for molybdenum-based powders is expected to grow as manufacturers use 3D printing for efficient prototyping and production of complex components. This trend opens new application avenues and offers potential cost reductions and performance improvements, reinforcing molybdenum's industrial value.

-

Regional Demand Shifts and Strategic Resource Security

Asia-Pacific, led by China, dominates molybdenum production and consumption due to large-scale steel manufacturing and infrastructure growth. China alone produces and consumes hundreds of millions of pounds annually, considering molybdenum a strategic resource. Meanwhile, regions like Europe and North America are increasing demand in aerospace, defense, and clean energy sectors. Governments are also focusing on securing molybdenum through supportive policies and reduced import duties, as seen in India's call for zero import duties on molybdenum ore to boost local industries. These regional dynamics highlight molybdenum's critical role in economic and security strategies worldwide.

Ask analyst of customized report: https://www.imarcgroup.com/request?type=report&id=5407&flag=E

Leading Companies Operating in the Global Molybdenum Industry:

-

ABSCO Limited

American CuMo Mining Corporation

Centerra Gold Inc.

China Molybdenum Co. Ltd.

China Rare Metal Material Co. Ltd.

Codelco

Freeport-McMoRan Inc.

Grupo México

Jinduicheng Molybdenum Co. Ltd

KGHM Polska Miedz S.A.

Molten Corporation

Moly Metal L.L.P

Molybdenum Market Report Segmentation:

By Product Type:

-

Steel

Chemical

Foundry

Molybdenum Metal

Nickel Alloy

Based on the product type, steel dominates as the largest segment in product type due to the extensive use of molybdenum in steel alloys, which enhances their strength and corrosion resistance, meeting the diverse demands of industries such as construction, automotive, and infrastructure development.

By Sales Channel:

-

Manufacturer/Distributor

Aftermarket

Based on the sales channel, the market is classified into manufacturer/distributor and aftermarket.

By End Use:

-

Oil and Gas

Automotive

Heavy Machinery

Energy

Aerospace and Defense

Others

Based on the end use, the market is divided into oil and gas, automotive, heavy machinery, energy, aerospace and defense, and others.

Regional Insights:

-

North America (United States, Canada)

Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

Latin America (Brazil, Mexico, Others)

Middle East and Africa

Based on the region, Asia Pacific holds the largest market share due to its rapid industrialization, significant growth in construction, automotive, and aerospace sectors, and the presence of emerging economies that have increasing demands for high-strength steel and other molybdenum-based products.

Note: If you require specific details, data, or insights that are not currently included in the scope of this report, we are happy to accommodate your request. As part of our customization service, we will gather and provide the additional information you need, tailored to your specific requirements. Please let us know your exact needs, and we will ensure the report is updated accordingly to meet your expectations.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales[@]imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-201971-6302

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment