Tomato Paste Manufacturing Plant Cost 2025: Business Plan, And Raw Materials Requirement

Setting up a tomato paste manufacturing plant requires a robust processing line. This includes sections for raw tomato reception, washing, sorting, crushing, and pre-heating to inactivate enzymes. The pulp is then refined to remove skin and seeds, followed by vacuum evaporation to concentrate the juice into a paste. Key equipment includes conveyors, washers, crushers, pulpers, evaporators, sterilizers, and aseptic filling machines. Sourcing high-quality, fresh tomatoes in season and ensuring efficient processing with strict hygiene are critical.

Request for a Sample Report : https://www.imarcgroup.com/tomato-paste-manufacturing-plant-project-report/requestsample

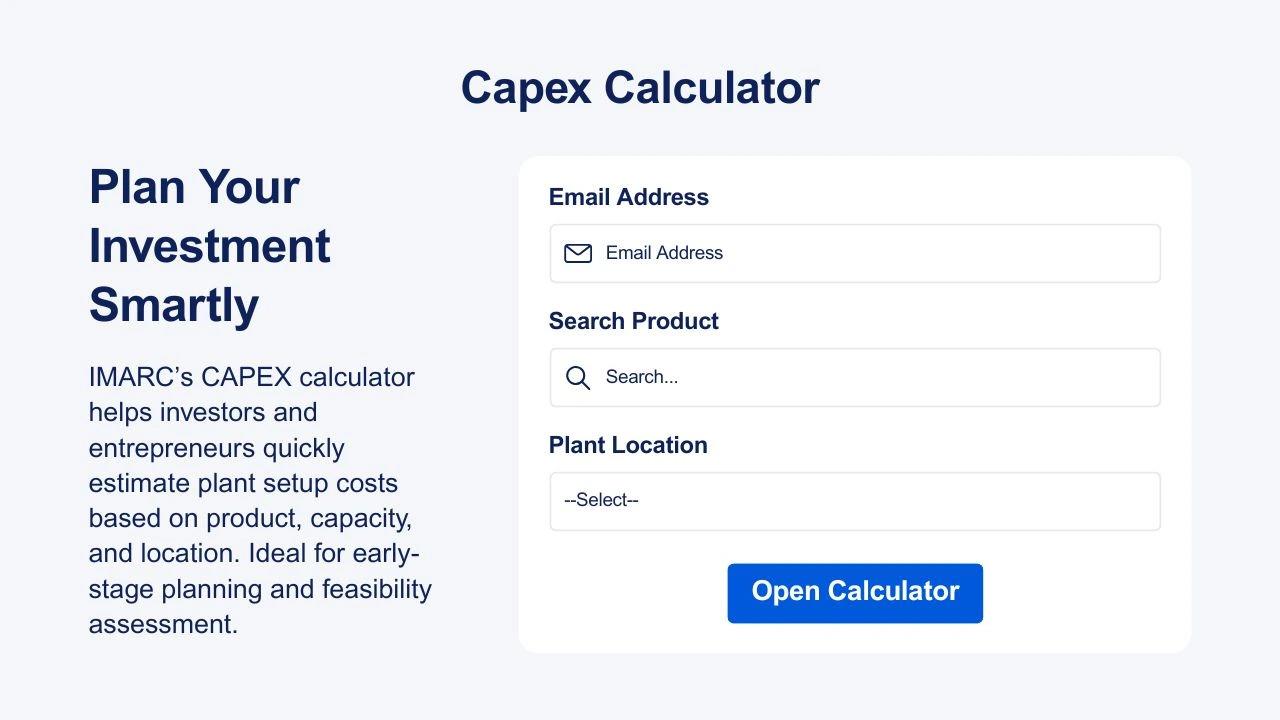

IMARC Group's “Tomato Paste Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” offers a detailed and practical guide for entrepreneurs and businesses looking to enter the manufacturing industry. The report includes in-depth analysis of capital investment requirements, project financing options, working capital needs, and projected returns.

This comprehensive business plan outlines every critical step involved in setting up a successful manufacturing plant unit from understanding the industry landscape to planning for real-world challenges. It provides valuable insights into essential components such as tomato paste manufacturing plant cost, machinery cost, operating cost, raw material requirements, utility needs, infrastructure setup, and packaging logistics.

Tomato Paste Industry Outlook 2025:

The tomato paste industry in India is poised for continued growth in 2025. This expansion is driven by the increasing demand for processed tomato products from the booming food sector, particularly for ready-to-eat meals, sauces, and ketchup. Rapid urbanization, changing consumer lifestyles, and a growing preference for convenient and versatile cooking ingredients will further fuel market demand. Modernization of processing facilities and improved packaging methods will also contribute to a positive outlook.

Key Insights for Tomato Paste Manufacturing Plant Setup:

Detailed Process Flow:

-

Product Overview

Unit Operations Involved

Mass Balance and Raw Material Requirements

Quality Assurance Criteria

Technical Tests

Project Details, Requirements and Costs Involved:

-

Land, Location and Site Development

Plant Layout

Machinery Requirements and Costs

Raw Material Requirements and Costs

Packaging Requirements and Costs

Transportation Requirements and Costs

Utility Requirements and Costs

Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

-

Capital Investments

Operating Costs

Expenditure Projections

Revenue Projections

Taxation and Depreciation

Profit Projections

Financial Analysis

Profitability Analysis:

-

Total Income

Total Expenditure

Gross Profit

Gross Margin

Net Profit

Net Margin

Request for Customization : https://www.imarcgroup.com/request?type=report&id=8690&flag=E

Key Cost Components of Setting Up a Tomato Paste Plant:

-

Land and Building Costs: Acquisition or lease of industrial land and construction of a food-processing facility, including raw tomato reception, processing areas (washing, crushing, pulping, evaporation), sterilization, aseptic filling, quality control lab, and warehousing.

Raw Material Procurement: Costs for securing a consistent and high-quality supply of fresh processing tomatoes from agricultural sources. This includes transportation, harvesting, and pre-cooling.

Packaging Materials: Costs for aseptic bags, drums, cans, jars, labels, and outer cartons for the finished tomato paste.

Utility & Energy Costs: Significant operational expenses for electricity (for machinery, refrigeration, HVAC), water (for washing, processing, steam generation), and fuel (for boilers). Tomato paste production is energy-intensive.

Labor and Staffing Costs: Salaries for food technologists, process engineers, quality control personnel, skilled machine operators, and general labor.

Quality Control and Testing Equipment: Investment in laboratory equipment for testing Brix (concentration), pH, color, consistency (Bostwick), microbial contamination, and overall product quality.

Licenses, Certifications, and Regulatory Compliance: Fees for food manufacturing licenses (FSSAI), environmental clearances, HACCP/ISO certifications for food safety, and compliance with packaging and labeling regulations.

Research & Development (R&D): Costs associated with developing new tomato varieties for processing, improving paste quality, or exploring new product applications.

Working Capital: Funds for initial raw material inventory, packaging materials, operational expenses, and salaries until sales revenue stabilizes.

Economic Trends Influencing Tomato Paste Plant Setup Costs 2025 :

-

Growth in Processed Food Consumption: The increasing consumption of processed foods, convenience foods, and international cuisines in India directly fuels demand for tomato paste as a key ingredient, encouraging investment in production capacity.

Fluctuating Tomato Prices and Availability: Seasonal variations, weather events, and agricultural output impact the price and consistent availability of fresh processing tomatoes, a major raw material cost.

Energy and Utility Costs: The energy-intensive nature of evaporation and sterilization processes means that rising industrial electricity, fuel, and water tariffs directly influence operational expenses for new plants.

Government Policies on Food Processing: Initiatives like the Pradhan Mantri Kisan Sampada Yojana (PMKSY) or other schemes promoting food processing can offer subsidies, tax benefits, or financial incentives, potentially reducing the effective setup cost.

Advancements in Processing Technology: Innovations in evaporation, sterilization, and aseptic filling technologies can offer efficiency gains but may require higher initial investment in advanced machinery.

Infrastructure Development: Improvements in cold chain logistics and transportation networks can reduce post-harvest losses and improve raw material supply chain efficiency, impacting overall costs.

Challenges and Considerations for Investors in Tomato Paste Plant Projects:

-

Raw Material Seasonality and Quality: Ensuring a consistent supply of suitable processing tomatoes outside of peak harvest seasons, and maintaining their quality upon arrival, is a significant challenge. Proximity to tomato-growing regions is crucial.

Post-Harvest Losses: Tomatoes are highly perishable, and significant losses can occur during harvesting, transportation, and storage if proper handling and cold chain management are not in place.

High Energy Consumption: The evaporation process is energy-intensive, leading to substantial operational costs. Investing in energy-efficient technologies is critical.

Wastewater Management: Tomato processing generates a significant volume of organic-rich wastewater, requiring effective and compliant effluent treatment plants (ETP) to meet environmental regulations.

Quality Control and Standardization: Maintaining consistent Brix levels, color, consistency, and microbial safety across batches is crucial for market acceptance and requires robust quality assurance systems.

Competition: The Indian market has existing players in the tomato processing sector. New entrants need to differentiate through quality, efficiency, cost-effectiveness, or specialized products.

Cold Chain and Storage: For fresh tomatoes and sometimes the finished product, maintaining an effective cold chain is vital to prevent spoilage and ensure product quality.

Market Price Volatility: Both raw tomato prices and finished tomato paste prices can fluctuate, impacting profitability and requiring effective risk management strategies.

Conclusion:

The tomato paste manufacturing industry in India presents a significant and growing investment opportunity for 2025, driven by the expanding demand from the processed food sector and evolving consumer preferences. While setting up a plant requires substantial capital investment, careful management of raw material seasonality and quality, and adherence to stringent food safety and environmental regulations, the essential role of tomato paste in various cuisines offers a compelling long-term prospect for investors prioritizing efficiency and quality.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales[@]imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302 )

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment