Plastic Crates Manufacturing Plant Report 2025: Raw Materials Requirement, Setup Cost And Revenue

Setting up a plastic crates manufacturing plant primarily involves the injection molding process. This requires a suitable industrial site with good utility access, especially reliable electricity. Key equipment includes large injection molding machines, specialized steel molds for specific crate designs, plastic granulators for raw material processing, and cooling systems. Sourcing high-quality plastic granules (HDPE/PP) consistently and implementing robust quality control for dimensions and strength are crucial for successful operation.

Request for a Sample Report : https://www.imarcgroup.com/plastic-crates-manufacturing-plant-project-report/requestsample

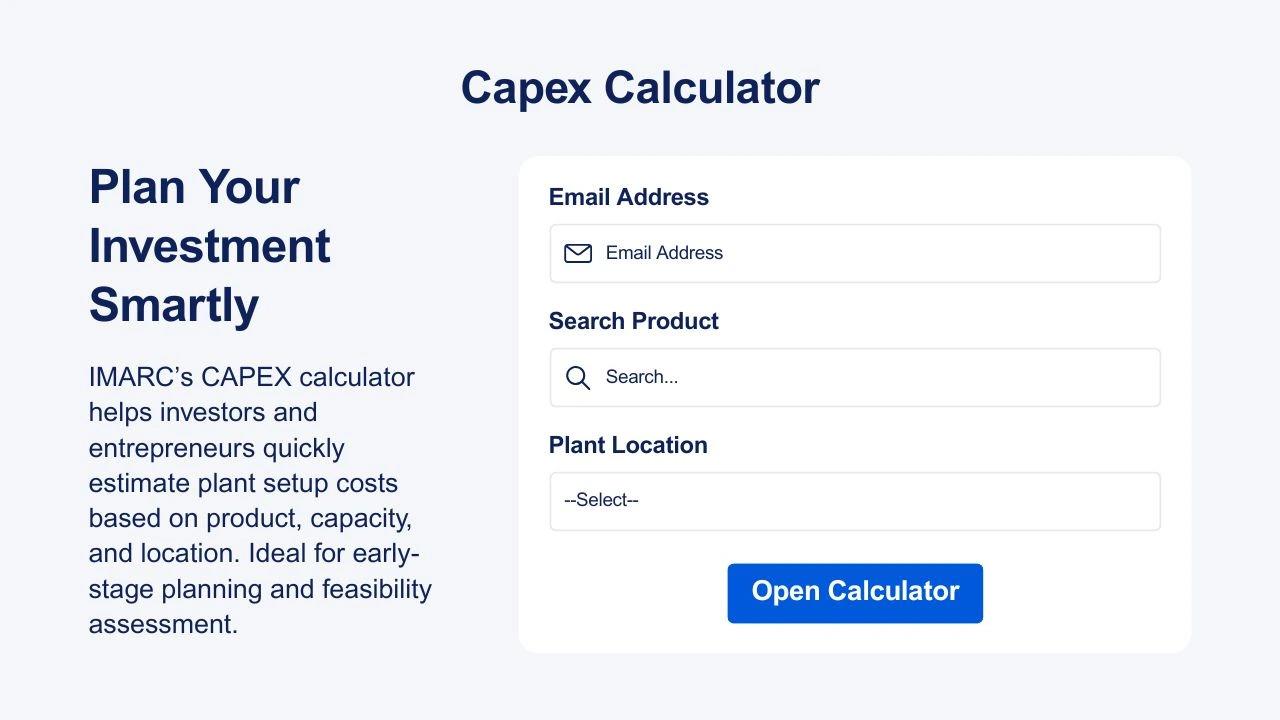

IMARC Group's report, titled “ Plastic Crates Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue,” provides a complete roadmap for setting up a plastic crates manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

This comprehensive business plan outlines every critical step involved in setting up a plastic crates manufacturing plant successful unit - from understanding the industry landscape to planning for real-world challenges. It provides valuable insights into essential components such as plastic crates manufacturing plant setup, cost breakdown, machinery cost, operating cost, raw material requirements, utility needs, infrastructure setup, and packaging logistics.

Plastic Crates Industry Outlook 2025:

The plastic crates market in India is forecasted for significant growth in 2025. This expansion is driven by globalization, increasing international trade, and the growing adoption of plastic crates across various end-user industries like food and beverages, industrial, retail, and pharmaceuticals. The advent of plasticulture and a rising focus on reusable, sustainable packaging solutions will further boost demand for these versatile containers.

Key Insights for Plastic Crates Manufacturing Plant Setup:

Detailed Process Flow:

-

Product Overview

Unit Operations Involved

Mass Balance and Raw Material Requirements

Quality Assurance Criteria

Technical Tests

Project Details, Requirements and Costs Involved:

-

Land, Location and Site Development

Plant Layout

Machinery Requirements and Costs

Raw Material Requirements and Costs

Packaging Requirements and Costs

Transportation Requirements and Costs

Utility Requirements and Costs

Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

-

Capital Investments

Operating Costs

Expenditure Projections

Revenue Projections

Taxation and Depreciation

Profit Projections

Financial Analysis

Profitability Analysis:

-

Total Income

Total Expenditure

Gross Profit

Gross Margin

Net Profit

Net Margin

Request for Customization : https://www.imarcgroup.com/request?type=report&id=19443&flag=E

Key Cost Components of Setting Up a Plastic Crates Plant:

-

Land & Building Costs: Acquisition or lease of industrial land and construction of a factory shed with designated areas for raw material storage, injection molding operations, cooling, quality control, and finished goods warehousing.

Injection Molding Machines: This represents the most significant capital expenditure. Costs vary based on clamping force, shot size, and automation level. Multiple machines are typically needed for high production capacity.

Molds/Dies: High-precision, durable steel molds designed for specific crate sizes and designs. Molds are expensive but critical for product quality, consistency, and efficient production.

Raw Material Sourcing: Initial and ongoing costs for procuring high-density polyethylene (HDPE) or polypropylene (PP) granules, along with color masterbatches and other additives.

Auxiliary Equipment: Includes plastic granulators (for recycling scrap), material dryers, auto-loaders for granules, chillers (for mold cooling), and air compressors.

Utility & Energy Costs: Significant expenses for electricity (for molding machines, chillers, air compressors), and water (for cooling systems). Injection molding is an energy-intensive process.

Labor & Staffing Costs: Salaries for skilled machine operators, technicians for maintenance, quality control personnel, and supervisory staff.

Quality Control & Testing Equipment: Equipment for checking dimensions, weight, load-bearing capacity, impact resistance, and material flow properties to ensure product standards are met.

Waste Management: Costs associated with collecting, grinding, and potentially reprocessing plastic waste (sprues, rejected pieces) for internal use or external recycling.

Licenses & Certifications: Fees for various industrial licenses, environmental clearances (from Pollution Control Board), and safety certifications.

Economic Trends Influencing Plastic Crates Plant Setup Costs 2025 :

-

Growth of End-User Industries: The expansion of sectors like food & beverage, logistics, retail, pharmaceuticals, and agriculture directly drives demand for plastic crates, influencing investment in production capacity.

Polymer Price Volatility: Fluctuations in the cost of HDPE and PP granules, which are petroleum-based, directly impact raw material costs. Global crude oil prices and supply-demand dynamics significantly influence this.

Energy Costs: Rising industrial electricity tariffs in India directly increase operational expenses for the energy-intensive injection molding process and auxiliary equipment.

Emphasis on Reusable Packaging: The growing focus on sustainability and circular economy principles drives demand for reusable plastic crates as an alternative to single-use packaging, potentially supporting higher production volumes.

Government Regulations on Plastics: Regulations, such as Extended Producer Responsibility (EPR) mandates and potential bans on certain single-use plastics, can indirectly influence the market by encouraging the use of more durable, reusable solutions like crates.

Interest Rates: Prevailing industrial loan interest rates directly affect the financing costs for substantial capital investments in machinery and infrastructure.

Challenges and Considerations for Investors in Plastic Crates Plant Projects:

-

High Initial Capital Investment: The substantial upfront cost of acquiring modern, large injection molding machines and durable, precise molds is a significant barrier to entry.

Raw Material Price Fluctuations: Volatility in the cost of plastic granules (HDPE, PP), which are petroleum derivatives, can unpredictably impact production costs and profit margins.

Energy Consumption: Injection molding is an energy-intensive process, making the plant susceptible to high and fluctuating electricity costs.

Competition: The market is competitive, with numerous established players. New entrants need to differentiate through quality, design, pricing, or specialized applications.

Environmental Concerns and Regulations: Increasing public and regulatory scrutiny over plastic waste necessitates investment in efficient recycling processes, waste management systems, and compliance with environmental norms.

Mold Maintenance and Lifespan: Molds are expensive and subject to wear and tear over high production cycles, requiring significant maintenance and eventual replacement costs.

Logistics and Distribution: Efficiently managing the transportation of bulky finished crates to a geographically dispersed customer base can be complex and costly.

Customization Demands: Meeting diverse customer demands for specific crate sizes, designs, colors, and features (e.g., ventilation, stack-nest capabilities) requires flexible mold management and production.

Conclusion:

The plastic crates manufacturing industry in India holds a promising outlook for 2025, propelled by robust growth in logistics, food, and retail sectors, alongside a growing emphasis on reusable packaging solutions. While setting up a plant requires significant capital outlay for advanced machinery and raw materials, and navigating challenges like raw material price volatility and environmental regulations, the increasing demand for durable, hygienic, and efficient material handling solutions positions this sector for sustained growth and profitability for discerning investors.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales[@]imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302 )

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment