Benz Delivers A New High Grade Gold Discovery At Glenburgh

| Hole number | Easting | Northing | Elevation | Max. depth | Dip | Azimuth | Comment |

| GBZ126_001 | 414751 | 7193776 | 317 | 396 | -70 | 145 | |

| GBZ126_002 | 414750 | 7193823 | 319 | 396 | -72 | 145 | |

| GBZ126_003 | 414616 | 7193732 | 322 | 420 | -72 | 145 | |

| GBZ126_004 | 414704 | 7193770 | 316 | 396 | -71 | 144 | |

| GBZ126_005 | 414669 | 7193870 | 318 | 574 | -75 | 145 | Full Assay results pending |

| GBZ126_006 | 414622 | 7193769 | 320 | 426 | -65 | 145 | |

| GBZ126_007 | 414724 | 7193798 | 317 | 366 | -55 | 145 | |

| GBZ126_008 | 414797 | 7193813 | 321 | 324 | -60 | 145 | |

| GBZ126_009 | 414688 | 7193875 | 307 | 402 | -57 | 145 | |

| GBZ126_010 | 414662 | 7193769 | 308 | 510 | -65 | 145 | |

| GBZ126_011 | 414618 | 7193784 | 312 | 462 | -59 | 145 | |

| GBZ126_012 | 414683 | 7193816 | 313 | 420 | -65 | 145 | |

| GBZ126_013 | 414760 | 7193821 | 313 | 318 | -65 | 145 | |

| GBZ126_014 | 414793 | 7193831 | 313 | 402 | -70 | 134 | Full Assay results pending |

Appendix 2: Significant Intercepts Table. Results reported >0.5g/t Au with 3m of allowed dilution.

| Hole ID | From | To | Au ppm | Interval | Comment |

| GBZ126_001 | 222 | 227 | 10.25 | 5.00 | New HG Lens |

| GBZ126_001 | 233 | 240 | 3.53 | 7.00 | |

| GBZ126_001 | 246 | 249 | 3.94 | 3.00 | |

| GBZ126_001 | 290 | 293 | 0.92 | 3.00 | |

| GBZ126_002 | 171 | 173 | 3.50 | 2.00 | |

| GBZ126_002 | 233 | 236 | 2.74 | 3.00 | |

| GBZ126_002 | 263 | 268 | 1.84 | 5.00 | |

| GBZ126_002 | 293 | 296 | 1.81 | 3.00 | New HG Lens |

| GBZ126_002 | 356 | 358 | 2.26 | 2.00 | |

| GBZ126_003 | 255 | 258 | 1.69 | 3.00 | |

| GBZ126_003 | 285 | 287 | 2.49 | 2.00 | |

| GBZ126_003 | 290 | 295 | 2.29 | 5.00 | |

| GBZ126_003 | 318 | 320 | 1.96 | 2.00 | |

| GBZ126_003 | 330 | 337 | 1.36 | 7.00 | |

| GBZ126_003 | 348 | 352 | 0.77 | 4.00 | |

| GBZ126_003 | 365 | 368 | 1.11 | 3.00 | |

| GBZ126_004 | 179 | 181 | 3.23 | 2.00 | |

| GBZ126_005 | 542 | 544 | 0.76 | 2.00 | |

| GBZ126_006 | 308 | 312 | 0.66 | 4.00 | |

| GBZ126_006 | 317 | 322 | 1.69 | 5.00 | |

| GBZ126_006 | 350 | 358 | 1.08 | 8.00 | |

| GBZ126_006 | 360 | 367 | 0.94 | 7.00 | |

| GBZ126_007 | 184 | 187 | 3.82 | 3.00 | |

| GBZ126_007 | 210 | 215 | 0.63 | 5.00 | |

| GBZ126_007 | 231 | 233 | 0.63 | 2.00 | |

| GBZ126_008 | 187 | 189 | 1.29 | 2.00 | |

| GBZ126_008 | 216 | 218 | 4.46 | 2.00 | |

| GBZ126_009 | 254 | 257 | 2.01 | 3.00 | |

| GBZ126_009 | 319 | 323 | 12.18 | 4.00 | New HG Lens |

| GBZ126_009 | 346 | 351 | 2.15 | 5.00 | |

| GBZ126_010 | 274 | 285 | 19.93 | 11.00 | New HG Lens |

| GBZ126_011 | 227 | 234 | 1.41 | 7.00 | |

| GBZ126_011 | 310 | 316 | 0.78 | 6.00 | |

| GBZ126_011 | 319 | 323 | 2.66 | 4.00 | |

| GBZ126_011 | 354 | 357 | 1.48 | 3.00 | |

| GBZ126_012 | 228 | 230 | 0.72 | 2.00 | |

| GBZ126_012 | 243 | 245 | 2.37 | 2.00 | |

| GBZ126_012 | 278 | 281 | 5.90 | 3.00 | |

| GBZ126_012 | 285 | 288 | 1.97 | 3.00 | |

| GBZ126_012 | 306 | 308 | 2.36 | 2.00 | |

| GBZ126_012 | 352 | 364 | 2.61 | 12.00 | New HG Lens |

| GBZ126_012 | 365 | 372 | 0.63 | 7.00 | |

| GBZ126_012 | 375 | 378 | 3.55 | 3.00 | |

| GBZ126_013 | 243 | 251 | 5.64 | 8.00 | New HG Lens |

Appendix 3: Individual 1m assay results for selected high grade significant intercepts.

| Hole number | From | To | Au ppm |

| GBZ126_001 | 222 | 223 | 3.2 |

| GBZ126_001 | 223 | 224 | 20.9 |

| GBZ126_001 | 224 | 225 | 16.7 |

| GBZ126_001 | 225 | 226 | 9.3 |

| GBZ126_001 | 226 | 227 | 1.1 |

| GBZ126_009 | 319 | 320 | 4.5 |

| GBZ126_009 | 320 | 321 | 38.8 |

| GBZ126_009 | 321 | 322 | 4.6 |

| GBZ126_009 | 322 | 323 | 0.8 |

| GBZ126_010 | 274 | 275 | 15.4 |

| GBZ126_010 | 275 | 276 | 16.4 |

| GBZ126_010 | 276 | 277 | 88.6 |

| GBZ126_010 | 277 | 278 | 40.0 |

| GBZ126_010 | 278 | 279 | 2.8 |

| GBZ126_010 | 279 | 280 | 2.2 |

| GBZ126_010 | 280 | 281 | 9.1 |

| GBZ126_010 | 281 | 282 | 3.3 |

| GBZ126_010 | 282 | 283 | 12.3 |

| GBZ126_010 | 283 | 284 | 27.0 |

| GBZ126_010 | 284 | 285 | 2.2 |

| GBZ126_013 | 243 | 244 | 11.2 |

| GBZ126_013 | 244 | 245 | 2.5 |

| GBZ126_013 | 245 | 246 | 1.6 |

| GBZ126_013 | 246 | 247 | 13.7 |

| GBZ126_013 | 247 | 248 | 7.7 |

| GBZ126_013 | 248 | 249 | 2.7 |

| GBZ126_013 | 249 | 250 | 4.9 |

| GBZ126_013 | 250 | 251 | 0.8 |

Appendix 4: JORC Tables

JORC Code, 2012 Edition - Table 1 report template

Section 1 Sampling Techniques and Data

(Criteria in this section apply to all succeeding sections)

| Criteria | Commentary |

| Sampling techniques |

RC drilling samples were collected as 1m single samples. Each sample collected represents each one (1) metre drilled collected from the rig-mounted cone splitter into individual calico bags (~3kg) and stored in labelled sequential polyweave bags for long-term storage. The rig mounted cyclone/cone splitter was levelled at the start of each hole to aid an even fall of the sample through the cyclone into the cone splitter. RC drilling sample submissions include the use of certified standards (CRMs), and field duplicates were added to the submitted sample sequence to test laboratory equipment calibrations. Standards selected are matched to the analytical method of photon assaying at ALS labs in Perth (~500g units). No composites were taken. Based on statistical analysis of these results, there is no evidence to suggest the samples are not representative. |

| Drilling techniques |

The booster was used to apply air to keep drill holes dry and reach deeper depths. |

| Drill sample recovery |

RC samples were visually checked for recovery, moisture and contamination. A cyclone and cone splitter were used to provide a uniform sample, and these were routinely cleaned. RC Sample recoveries are generally high. No significant sample loss has been recorded. |

| Logging |

Geological logging is considered appropriate for this style of deposit (metamorphosed orogenic gold). The entire length of all holes has been geologically logged. RC drill logging was completed by Galt Mining Solutions staff and data entered into BNZ's MXDeposit digital data collection platform provided by Expedio. All drill chips were collected into 20 compartment-trays for future reference and stored at Galt's warehouse in West Leederville at the time of reporting. |

| Sub-sampling techniques and sample preparation |

A sample size of between 3 and 5 kg was collected. This size is considered appropriate, and representative of the material being sampled given the width and continuity of the intersections, and the grain size of the material being collected. For the 1 metre samples, certified analytical standards (appropriate for photon assaying) and field duplicates were inserted at appropriate intervals at a rate equal to 1 in 20 and sent for analysis with the samples. Sample preparation was undertaken at ALS Laboratory - Perth. Gold analysis utilised the photon assaying methodology where original samples are crushed to 2mm with a sub-set 500g separated for non-destructive analysis. Any sample reporting as having elevated > 1μSv readings during the preparation for photon assaying at ALS labs were flagged and were submitted for fire assay (Au-AA26) methodology at ALS labs in Perth as a quantifying check against the Photon assays. |

| Quality of assay data and laboratory tests |

The scanning of sieved RC drilling fines sample material utilised an Olympus Vanta M Series portable XRF in Geochem mode (3 beam) and a 20-second read time for each beam (Instrument_Serial = 840951). The ASD data reader on Boxscan has a 3 nm VNIR, 6 nm SWIR spectral resolution of the LabSpec 4 Hi-Res analytical instrument (Electronics serial number: 28191). The pXRF and ASD are incorporated into Geotek's Boxscan machine to facilitate an automated data collection process. This includes periodic calibration and QAQC scans on Geotek-supplied pucks and colour strips. The QAQC scans are verified and checked on Boxscan's internal program datasheet against expected results to ensure the analysers are conforming to Boxscan's expected operating parameters. A review of the pXRF and ASD sample results provided an acceptable level of analysis and the data is appropriate for reporting the geochemistry results in the context of its use for screening areas for indications of elevations in concentrations with elements of interest. pXRF and ASD results should never be considered a proxy or substitute for laboratory analysis, which is required to determine robust and accurate potential for mineralisation and associated elements. The reporting of pXRF and ASD results should not be described as an "assay" result, as these are not of the same level of accuracy or precision as that obtained from a certified laboratory workflow. The use of "preliminary indicative field data" is a more appropriate term when referring to pXRF and ASD results. The pXRF data is exploratory in nature and is used predominantly as an internal workflow to assist in target prioritisation through an early phase of exploration investigation. No previous comparisons of pXRF and ASD data with laboratory data at the project have been undertaken to date. The analysis involved direct point counting on the raw surfaces of the supplied drill fines. The fines are transferred from geochem packets to purpose-made scanning pucks, with the analysis taken from the middle of these pucks. The sample material was dry and collected and analysed in ambient temperatures within the processing warehouse. Monitoring of workstation area and apparatus temperatures occur during the shift with cooling actions being implemented when required. This provides only semi-quantitative information and is reported as raw data without significant corrections, which is best interpreted as an abundant/present/absent classification for most elements. This information provides useful trend analyses at an exploration target scale. |

| Verification of sampling and assaying |

No twinned holes have been drilled to date by Benz Mining, but, planned holes have tested the interpreted mineralised trends, verifying the geometry of the mineralised targets. All logs were validated by the Project Geologist prior to being sent to the Database Administrator for import No adjustments have been made to assay data received from ALS labs. |

| Location of data points |

The grid system used for the location of all drill holes is GDA94_MGA _Zone 50s. Planned hole coordinates and final GPS coordinates are compared in QGIS and Leapfrog project files to ensure all targets have been tested as intended. The drill string path is monitored as drilling progresses using downhole Axis Champ Gyro tool and compared against the planned drill path, adjustment to the drilling technique is requested as required to ensure the intended path is followed. Readings were recorded at 30m intervals from surface to end of hole after Benz reviewed single shot verses EOH continuous surveying of the Axis Champ Gyro tool and noted >3 degrees variance in azimuth with hole depth. The single shots produce less variability and are used for hole trace reporting in the database. Historical drill hole surveys and methods will be reviewed in preparation for any updates to MRE in the future. |

| Data spacing and distribution |

The mineralised domains established for pre-BNZ MREs have sufficient continuity in both geology and grade to be considered appropriate for the Mineral Resource and Ore Reserve estimation procedures and classification applied under the 2012 JORC Code. Ongoing drilling will be sufficiently spaced for a reinterpretation based on BNZ's structural model. No sample compositing of material from drilling has been applied during this drilling campaign. |

| Orientation of data in relation to geological structure |

No orientation-based sampling bias has been identified - observed intercepts to date indicate the interpreted geology hosting mineralisation is robust. |

| Sample security |

Individual pre-numbered calco sample bags are placed in polywoven plastic bags (5 per bag) secured at the top with a cable tie. These bags are annotated with the company name and sample numbers, the bags are placed in larger bulker bags for transport to ALS labs in Perth, also labelled with corresponding company name, drill hole and sample identifiers. Sample pulps are stored in a dry, secure location at Galt's warehouse in West Leederville. |

| Audits or reviews |

All drilled hole collars have been located with a DGPS. There have been no audits undertaken. |

Section 2 Reporting of Exploration Results

(Criteria listed in the preceding section also apply to this section)

| Criteria | Commentary |

| Mineral tenement and land tenure status |

The tenement is 100% owned by Benz Mining Limited. The tenements are in good standing and no known impediments exist. |

| Exploration done by other parties |

9 diamond holes, 398 RC holes, 6 air-core holes and 462 RAB holes have been drilled in the Glenburgh area to identify the distribution and evaluate the potential of the deposit. Drilling to date has identified 10 high potential deposits in the Glenburgh area which are: Tuxedo, Icon, Apollo, Mustang, Shelby, Hurricane, Zone 102, Zone 126, NE3 and NE4 deposits. |

| Geology |

Gold was first discovered at the Glenburgh deposit in 1994 by Helix Resources during follow-up drilling of soil geochemical anomalies. Mineralisation occurs in shears within quartz + feldspar + biotite ± garnet gneiss, which contains discontinuous blocks or lenses of amphibolite and occasional thin magnetite-bearing metamorphics, probably derived from chemical sediments. Higher-grade mineralisation appears to be directly related to silica flooding in the gneiss. This silica flooding may give rise to quartz 'veins' up to several metres thick, although scales of several centimetres to tens of centimetres are the norm. Neither the higher-grade silica lodes nor the more pervasive lower-grade mineralisation exhibits sharp or well-defined lithological contacts. |

| Drill hole Information |

Collar details have been provided in the body of the report. For earlier released results, see previous announcements by Gascoyne Resources and Spartan Resources. |

| Data aggregation methods |

A nominal 0.5 ppm Au lower cut off has been applied to the RC and results, with up to 3m internal dilution (<0.5ppm Au) included if appropriate. Higher grade Au intervals lying within broader zones of Au mineralisation are reported as included intervals. No top cuts have been applied to reported intercepts. No metal equivalent values have been used. All reported assays have been length weighted if appropriate. |

| Relationship between mineralisation widths and intercept lengths |

Direct exposure of the targeted geological contact is not known at this stage, hence all reported intercepts are as down hole widths and not true widths. |

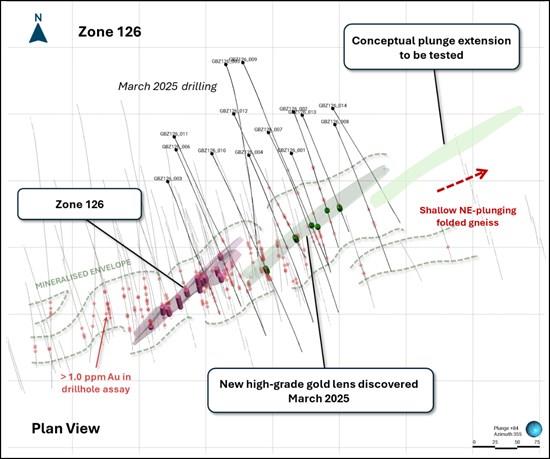

| Diagrams |

|

| Balanced reporting |

|

| Other substantive exploration data |

|

| Further work |

Detailed field mapping has commenced to refine targets for the next round of drilling. Geophysical techniques are being investigated to reduce the search space of high-grade lenses away from defined resource areas and/or high-grade drill intercepts. |

________________________

1 See Benz announcement dated 6 November 2024

2 Indicated: 13.5Mt at 1.0g/t Au for 430.7koz; Inferred: 2.8Mt at 0.9g/t Au for 79.4koz. See Historical Mineral Resource Estimates, below

3 Indicated: 1.3Mt at 9.0g/t Au for 384koz; Inferred: 3.8Mt at 5.1g/t Au for 621koz

To view the source version of this press release, please visit

SOURCE: Benz Mining Corp.

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment