403

Sorry!!

Error! We're sorry, but the page you were looking for doesn't exist.

RIT Dubai project reinvents campus plastic waste to produce 3D printing materials

(MENAFN- The Loop) Innovation transforms global challenge into sustainable solution

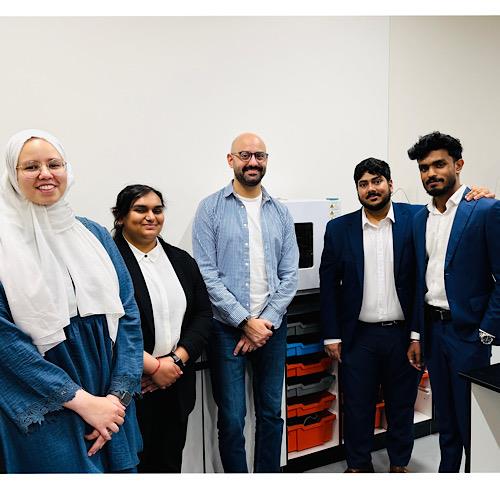

As the world struggles with growing plastic waste, a team of mechanical engineering students from Rochester Institute of Technology (RIT) of Dubai has trialled an innovative approach to turning this global challenge into a sustainable solution. As part of their graduation project, Reem Aly, Shriya Vijay, Vishnu Shyju, and Muhammed Sharfuddin, worked under the supervision of Dr. Wael A. Samad, Chair of the Department of Mechanical & Industrial Engineering, to transform discarded water bottles into usable filament for 3D printing.

Collecting bottles from around campus, the team took on the challenge of recycling the common PET (Polyethylene Terephthalate) plastics, the kind used for everyday water bottles. The students shredded the plastic into flakes, dried it to remove moisture and prevent hydrolytic degradation, and extruded it into recycled filament. The experiment demonstrates that, on average, 12 standard 1.5-liter bottles would be enough to produce a 30-meter spool of filament, fully compatible with any desktop FDM 3D printer.

The student-led project builds on previous research projects at RIT Dubai, including the university’s success in securing the prestigious DEWA Al Baheth research grant in 2023–24, which focused on sustainable 3D printing solutions. Speaking about the challenges and the significance of the most recent project, Dr. Samad said, “Processing PET is far from straightforward as it has specific characteristics that create a very narrow processing window. Despite these engineering difficulties, the team optimized processing and print parameters and benchmarked their recycled PET against commercially available filaments in the market.”

The research is also the subject of a paper entitled, ‘Sustainable Filament Production: Recycling Plastic Water Bottles into High-Quality 3D Printing Filaments’. Speaking about the potential application of the project beyond the academic realm, Dr. Samad added, “Recycled PET filaments do come with trade-offs compared to commercial filaments, but they also offer unique advantages. This project has demonstrated that 3D-printed parts made from recycled PET possess properties that make them a promising choice for applications where sustainability is a priority, particularly in prototyping and low-load bearing applications.”

With an estimated 500 billion plastic bottles used every year – equating to more than 1 million bottles every minute – most of which are still not recycled, the project contributes to the global movement towards innovative solutions for a more sustainable future. At a local level, the research demonstrates how small-scale, local action can support strategic initiatives like the UAE’s Green Agenda 2030.

Dr. Samad concluded, “What I find most exciting is seeing our students use rigorous engineering methods to transform waste into opportunity. Projects like this not only prepare them to tackle global challenges but also align closely with the UAE’s drive toward sustainability and innovation.”

----------

As the world struggles with growing plastic waste, a team of mechanical engineering students from Rochester Institute of Technology (RIT) of Dubai has trialled an innovative approach to turning this global challenge into a sustainable solution. As part of their graduation project, Reem Aly, Shriya Vijay, Vishnu Shyju, and Muhammed Sharfuddin, worked under the supervision of Dr. Wael A. Samad, Chair of the Department of Mechanical & Industrial Engineering, to transform discarded water bottles into usable filament for 3D printing.

Collecting bottles from around campus, the team took on the challenge of recycling the common PET (Polyethylene Terephthalate) plastics, the kind used for everyday water bottles. The students shredded the plastic into flakes, dried it to remove moisture and prevent hydrolytic degradation, and extruded it into recycled filament. The experiment demonstrates that, on average, 12 standard 1.5-liter bottles would be enough to produce a 30-meter spool of filament, fully compatible with any desktop FDM 3D printer.

The student-led project builds on previous research projects at RIT Dubai, including the university’s success in securing the prestigious DEWA Al Baheth research grant in 2023–24, which focused on sustainable 3D printing solutions. Speaking about the challenges and the significance of the most recent project, Dr. Samad said, “Processing PET is far from straightforward as it has specific characteristics that create a very narrow processing window. Despite these engineering difficulties, the team optimized processing and print parameters and benchmarked their recycled PET against commercially available filaments in the market.”

The research is also the subject of a paper entitled, ‘Sustainable Filament Production: Recycling Plastic Water Bottles into High-Quality 3D Printing Filaments’. Speaking about the potential application of the project beyond the academic realm, Dr. Samad added, “Recycled PET filaments do come with trade-offs compared to commercial filaments, but they also offer unique advantages. This project has demonstrated that 3D-printed parts made from recycled PET possess properties that make them a promising choice for applications where sustainability is a priority, particularly in prototyping and low-load bearing applications.”

With an estimated 500 billion plastic bottles used every year – equating to more than 1 million bottles every minute – most of which are still not recycled, the project contributes to the global movement towards innovative solutions for a more sustainable future. At a local level, the research demonstrates how small-scale, local action can support strategic initiatives like the UAE’s Green Agenda 2030.

Dr. Samad concluded, “What I find most exciting is seeing our students use rigorous engineering methods to transform waste into opportunity. Projects like this not only prepare them to tackle global challenges but also align closely with the UAE’s drive toward sustainability and innovation.”

----------

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment