Top CNC Lathe Machine Cleaning Tips For Optimal Performance

1. Weekly Maintenance

- Clean electrical cabinet ventilation filters to prevent dust accumulation and overheating.

- Check hydraulic/pneumatic system pressure for stability and inspect pipelines for leaks.

- Remove sediment from coolant tank and verify concentration and pH levels.

2. Monthly Maintenance

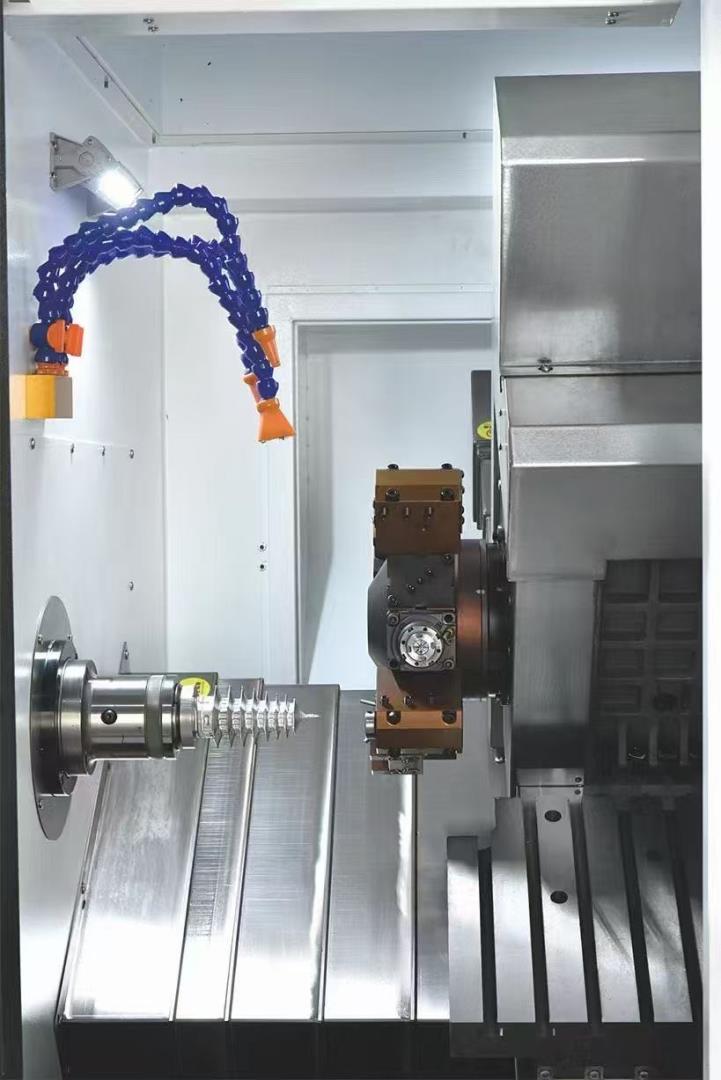

- Guide rails & ball screws: Clean with kerosene or specialized solvent, then relubricate; inspect for wear or scoring.

- Spindle system: Check taper cleanliness and apply light rust-preventive oil.

- Electrical system: Inspect cables and connectors for looseness, and verify proper grounding.

3. Quarterly Maintenance

- Hydraulic system: Replace or filter hydraulic oil and clean the reservoir.

- Accuracy calibration: Verify machine geometry (e.g., levelness, spindle runout, backlash).

- Data backup: Save CNC parameters and PLC programs to prevent data loss.

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment