Underwater Navigation Robot Inspects Nuclear Reactor Vessels In Japan

October 10, 2025 by Mai Tao

Mitsubishi Heavy Industries has developed a specialised underwater navigation robot to perform non-destructive inspections of nuclear reactor vessels in high-radiation environments, according to information released by the Japan Society of Maintenology. (See videos below.)

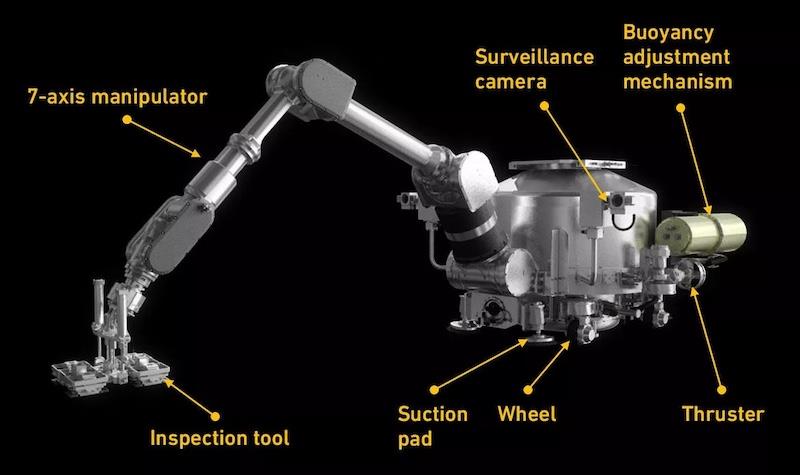

The unit, known as the A-UT Machine, is designed to navigate reactor vessels underwater and carry out weld-line inspections using a manipulator arm.

“The unit navigates underwater and uses a manipulator to perform non-destructive inspections of the weld lines of a nuclear reactor vessel,” Mitsubishi developers said.

The machine measures 1.8 metres in length, one metre in width, and 0.9 metres in height. It weighs 400 kilograms, although this drops to zero when submerged.

It moves using thrusters and wheels that allow it to travel along wall surfaces. The manipulator arm is a seven-axis design, capable of carrying a 10-kilogram load with positioning precision of ±0.1 millimetres.

“The manipulator features a tool changer at the tip, meaning that inspection tools can be switched out for others,” according to the developers.

The robot can operate at depths of up to 20 metres. Its position is tracked in real time using a target mounted on the robot, with triangulation used to ensure accurate orientation.

“Simultaneously operating two units greatly reduces the time required for an inspection,” the developers said. Control is carried out remotely using a desktop computer and joystick.

The system has been in service at pressurised water reactor (PWR) plants in Japan since 1995, with 46 deployments recorded to date.

“The unit has been certified as the #1 Maintenance Heritage by the Japan Society of Maintenology,” the developers noted. The society defines a Maintenance Heritage as a“historic heritage related to maintenance technology also constituting a cultural heritage of humankind”.

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Most popular stories

Market Research

- Crypto Market Update: Pepeto Advances Presale With Staking Rewards And Live Exchange Demo

- Kucoin Appeals FINTRAC Decision, Reaffirms Commitment To Compliance

- Cregis And Sumsub Host Web3 Compliance And Trust Summit In Singapore

- Chartis Research And Metrika Release Comprehensive Framework For Managing Digital Asset Risk

- Nodepay Launches Crypto's Largest Prediction Intelligence Platform

- Schoenherr Opens London Liaison Office As Gateway To Central Eastern Europe

Comments

No comment