Egg Tray Manufacturing Plant Report 2025- Setup Details, Machinery Requirements And Cost Analysis

Setting up an egg tray manufacturing plant involves procuring pulp molding machinery, establishing raw material supply chains, and arranging drying systems. With compact machinery, minimal space, and basic utilities, small-scale plants can operate efficiently at low investment levels.

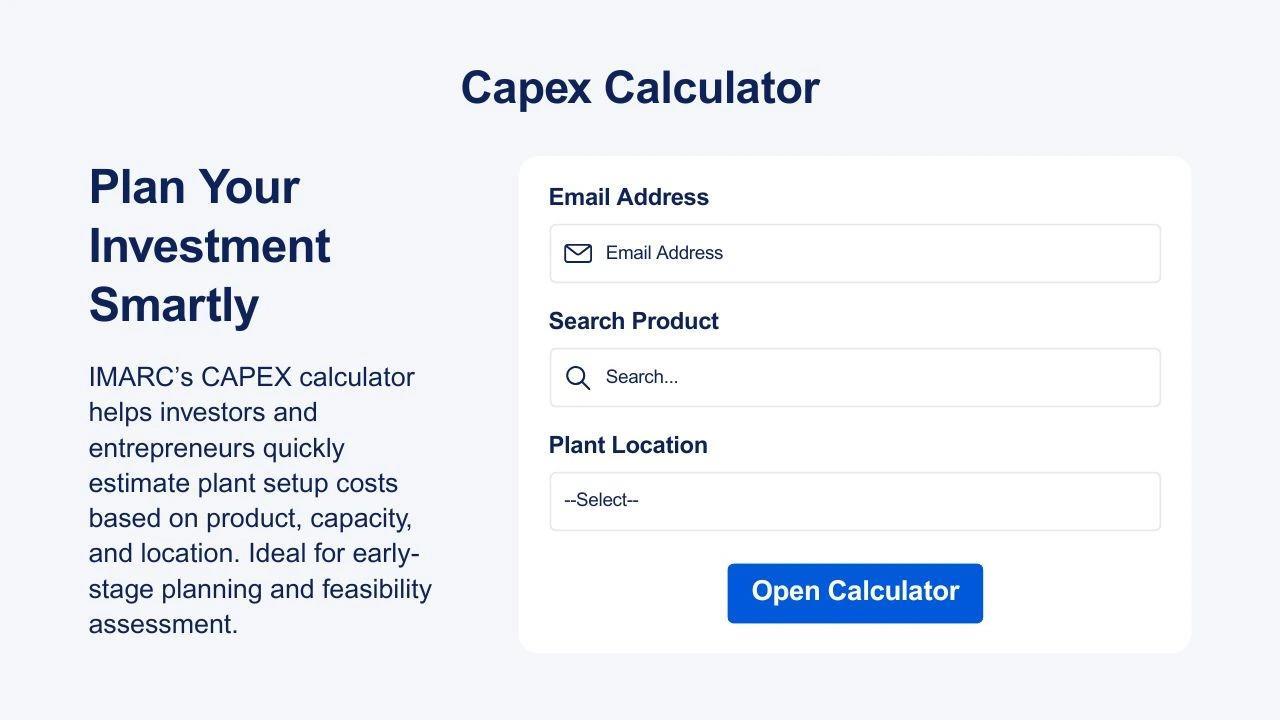

IMARC Group's report, titled “ Egg Tray Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue,” provides a complete roadmap for setting up an egg tray manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Request for a Sample Report : https://www.imarcgroup.com/egg-tray-manufacturing-plant-project-report/requestsample

Egg Tray Industry outlook 2025:

The egg tray industry outlook for 2025 remains positive, driven by rising global egg consumption, increasing focus on sustainable packaging, and growth in the poultry sector. Demand is expected to strengthen in both developed and emerging markets, with biodegradable pulp trays gaining preference over plastic alternatives due to environmental regulations. Technological advancements in pulp moulding and automation are enhancing production efficiency and cost-effectiveness, making small and medium-scale manufacturing more viable. Asia-Pacific is projected to dominate market share, supported by large-scale poultry production, while North America and Europe will see steady growth fuelled by sustainability trends and consumer preference for eco-friendly packaging.

Key Insights for Egg Tray Manufacturing Plant Setup:

Detailed Process Flow:

-

Product Overview

Unit Operations Involved

Mass Balance and Raw Material Requirements

Quality Assurance Criteria

Technical Tests

Project Details, Requirements and Costs Involved:

-

Land, Location and Site Development

Plant Layout

Machinery Requirements and Costs

Raw Material Requirements and Costs

Packaging Requirements and Costs

Transportation Requirements and Costs

Utility Requirements and Costs

Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

-

Capital Investments

Operating Costs

Expenditure Projections

Revenue Projections

Taxation and Depreciation

Profit Projections

Financial Analysis

Profitability Analysis:

-

Total Income

Total Expenditure

Gross Profit

Gross Margin

Net Profit

Net Margin

Key Cost Components of Setting Up an Egg Tray Plant :

-

Machinery and Equipment: Pulp moulding machines, drying systems, and ancillary equipment.

Raw Materials: Wastepaper, water, and chemical additives for pulp preparation.

Land and Infrastructure: Factory space, utilities, and building construction or rental costs.

Labor Costs: Skilled and unskilled workforce for operations, maintenance, and management.

Energy and Utilities: Electricity, water supply, and fuel for drying processes.

Packaging and Logistics: Materials for packing trays and transportation expenses.

Maintenance and Spare Parts: Regular upkeep of machinery and replacement parts.

Licensing and Compliance: Permits, environmental clearances, and quality certifications.

Economic Trends Influencing Egg Tray Plant Setup Costs 2025 :

-

Raw Material Price Fluctuations: Variability in wastepaper and recycled pulp prices due to global demand and recycling rates.

Energy Cost Volatility: Rising electricity and fuel prices affecting production and drying operations.

Inflationary Pressures: Increased costs of labour, construction, and machinery imports.

Currency Exchange Rates: Impact on imported machinery and spare parts for plants relying on foreign suppliers.

Environmental Regulations: Compliance with stricter eco-friendly manufacturing standards increasing initial investment.

Technological Advancements: Adoption of automation and energy-efficient systems altering capital expenditure requirements.

Regional Economic Growth: Poultry sector expansion driving local demand and influencing plant scale decisions.

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=7433&flag=E

Challenges and Considerations for Investors in Egg Tray Plant Projects:

-

Market Demand Variability: Dependence on poultry industry performance and seasonal fluctuations in egg consumption.

Competition and Pricing Pressure: Presence of low-cost producers affecting profit margins.

Raw Material Supply Stability: Ensuring consistent access to quality wastepaper or pulp.

Technological Selection: Balancing between automation for efficiency and initial investment constraints.

Regulatory Compliance: Meeting environmental, safety, and packaging standards.

Operational Expertise: Need for skilled workforce to maintain product quality and efficiency.

Logistics and Distribution: Efficient delivery systems to reach target markets cost-effectively.

Conclusion:

The egg tray manufacturing industry in 2025 presents strong growth potential, supported by rising egg consumption, sustainability-driven packaging demand, and advancements in pulp moulding technology. While opportunities are significant, investors must account for factors such as raw material availability, energy costs, regulatory compliance, and competitive pricing pressures. Strategic planning in machinery selection, supply chain management, and market positioning is essential for long-term profitability. With the right balance of cost control, operational efficiency, and adherence to eco-friendly practices, an egg tray plant can become a sustainable and lucrative venture in the evolving global packaging market.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales[@]imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment