Oral Rehydration Salt (ORS) Manufacturing Plant Cost 2025: Project Report, Machinery, And Raw Materials

Oral Rehydration Salt (ORS) is a life-saving, cost-effective formulation of glucose and electrolytes (sodium, potassium, chloride, citrate) designed to treat and prevent dehydration, particularly caused by diarrhea. When dissolved in clean water, ORS facilitates the absorption of water and salts into the body, effectively replenishing lost fluids and preventing severe complications, especially in children and vulnerable populations. Its precise composition, typically adhering to WHO/UNICEF guidelines, makes it superior to plain water or sugary drinks for rehydration.

Setting up an ORS manufacturing plant involves careful selection of a hygienic facility, as it's a pharmaceutical product. Key steps include sourcing pharmaceutical-grade raw materials like dextrose, sodium chloride, potassium chloride, and sodium citrate. Essential machinery comprises precise weighing and blending equipment for accurate formulation, granulation or direct compression machines, and automated sachet or pouch packing lines. Strict adherence to Good Manufacturing Practices (GMP) and obtaining necessary drug manufacturing licenses and quality certifications are paramount for production and market entry.

Request for a Sample Report : https://www.imarcgroup.com/oral-rehydration-salt-manufacturing-plant-project-report/requestsample

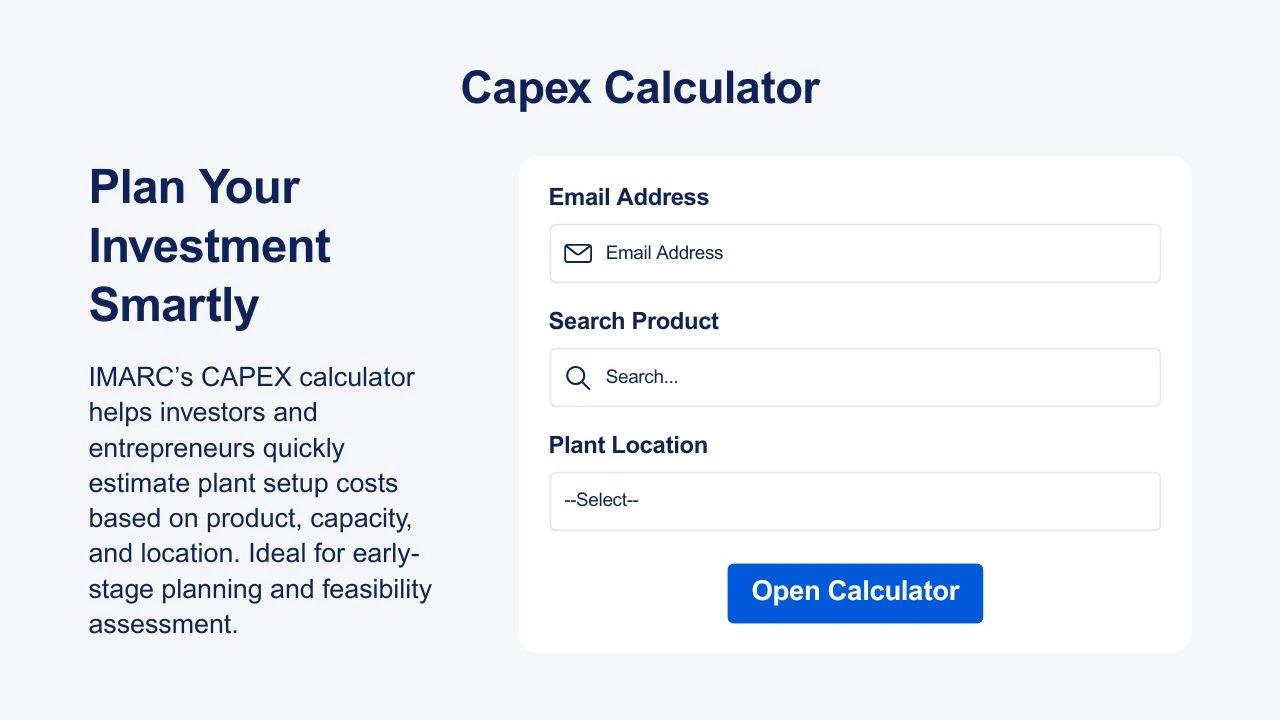

IMARC Group's report, titled “ Oral Rehydration Salt (ORS) Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue,” provides a complete roadmap for setting up an oral rehydration salt (ORS) manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

This comprehensive business plan outlines every critical step involved in setting up a oral rehydration salt (ORS) manufacturing plant successful unit - from understanding the industry landscape to planning for real-world challenges. It provides valuable insights into essential components such as oral rehydration salt (ORS) manufacturing plant setup, cost breakdown, machinery cost, operating cost, raw material requirements, utility needs, infrastructure setup, and packaging logistics.

Oral Rehydration Salt ( ORS ) Industry Outlook 2025:

The ORS industry in India is poised for strong growth in 2025. This is primarily driven by the high prevalence of diarrheal diseases, especially in rural and low-income areas. Increased awareness campaigns by government and NGOs promoting ORS as a first-line treatment, coupled with improved accessibility through wider distribution networks, are key accelerators. Innovations like flavored ORS and ready-to-drink formulations are also enhancing consumer acceptance and convenience, ensuring a positive market trajectory.

Key Insights for Oral Rehydration Salt (ORS) Manufacturing Plant Setup:

Detailed Process Flow:

-

Product Overview

Unit Operations Involved

Mass Balance and Raw Material Requirements

Quality Assurance Criteria

Technical Tests

Project Details, Requirements and Costs Involved:

-

Land, Location and Site Development

Plant Layout

Machinery Requirements and Costs

Raw Material Requirements and Costs

Packaging Requirements and Costs

Transportation Requirements and Costs

Utility Requirements and Costs

Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

-

Capital Investments

Operating Costs

Expenditure Projections

Revenue Projections

Taxation and Depreciation

Profit Projections

Financial Analysis

Profitability Analysis:

-

Total Income

Total Expenditure

Gross Profit

Gross Margin

Net Profit

Net Margin

Request for Customization : https://www.imarcgroup.com/request?type=report&id=9632&flag=E

Key Cost Components of Setting Up an Oral Rehydration Salt (ORS) Plant:

-

Land and Building Costs: Acquisition or lease of land and construction of a pharmaceutical-grade facility, including cleanrooms, raw material storage, mixing, granulation/compression, packaging, quality control labs, and finished goods warehousing. Adherence to GMP guidelines significantly impacts construction costs.

Raw Material Procurement: Costs for sourcing pharmaceutical-grade glucose (dextrose anhydrous), sodium chloride, potassium chloride, trisodium citrate dihydrate, and any flavoring agents or excipients.

Utility & Energy Costs: Costs for electricity (for machinery, HVAC), water (for purification, processing, cleaning), and steam (for sterilization, drying).

Labor and Staffing Costs: Salaries for qualified pharmacists, chemists, microbiologists, quality assurance/control personnel, skilled machine operators, and support staff.

Licenses, Certifications, and Regulatory Compliance: Fees for drug manufacturing licenses (e.g., from State Drug Control Department, CDSCO), GMP certification, environmental clearances, and regular audits. This includes costs for documentation and compliance management.

Working Capital: Funds for initial raw material inventory, packaging materials, operational expenses, utilities, and salaries before sales revenue stabilizes.

Economic Trends Influencing Oral Rehydration Salt (ORS) Plant Setup Costs 2025 :

-

Public Health Priorities: Increased government spending and international aid for public health initiatives, especially for child health and infectious disease control, can create a stable market and potentially lead to incentives for local ORS production.

Inflation in Pharmaceutical Raw Materials: Fluctuations in global prices of pharmaceutical-grade chemicals (glucose, salts) can directly impact raw material procurement costs.

Energy Prices: As ORS production involves processes like drying and HVAC for cleanrooms, rising electricity and fuel costs directly influence operational expenses.

“Make in India” Initiatives: Government emphasis on domestic manufacturing for essential medicines can lead to policy support, subsidies, or easier financing for setting up ORS plants, reducing effective setup costs.

Healthcare Infrastructure Expansion: Growth in the number of pharmacies, primary health centers, and hospitals, particularly in rural areas, expands the distribution network and market reach for ORS.

Increasing Health Awareness: Public health campaigns and media outreach increase consumer awareness about ORS, driving demand and justifying investment in higher production capacities.

Challenges and Considerations for Investors in Oral Rehydration Salt (ORS) Plant Projects:

-

Stringent Regulatory Compliance: Adhering to Good Manufacturing Practices (GMP) and obtaining necessary drug licenses is highly complex, requiring meticulous documentation, stringent quality control, and significant investment in infrastructure and processes.

Quality Control: Ensuring the precise composition and purity of each ORS sachet is critical for efficacy and patient safety. Any deviation can render the product ineffective or harmful, necessitating robust in-process and finished product testing.

Raw Material Quality and Sourcing: Sourcing pharmaceutical-grade raw materials consistently and ensuring their quality and authenticity can be challenging, especially for smaller manufacturers.

Competition and Pricing Pressure: The ORS market in India includes both large pharmaceutical companies and numerous smaller players, leading to significant competition and potential pricing pressures, especially for generic formulations.

Distribution and Reach: Effectively distributing ORS to remote and rural areas, where it is most needed, requires a robust and often complex supply chain and distribution network.

Awareness and Education: Despite its importance, a lack of awareness or misconceptions about ORS in certain communities can hinder adoption, requiring continuous educational efforts.

Shelf Life and Stability: Ensuring the stability and shelf life of the ORS powder, particularly in varied climatic conditions, requires appropriate packaging and storage solutions.

Conclusion:

The Oral Rehydration Salt (ORS) manufacturing industry in India presents a vital and growing investment opportunity for 2025, driven by critical public health needs and increasing awareness. While setting up an ORS plant necessitates substantial capital investment, stringent regulatory adherence, and meticulous quality control, the undeniable demand for this life-saving product, coupled with supportive governmental and public health initiatives, offers a compelling prospect for investors committed to quality and social impact. Strategic planning and a robust distribution network will be key to success in this essential sector.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales[@]imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302 )

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment