Diethylmalonate Production Cost Analysis 2025: Raw Material, And Investment Overview

Diethylmalonate, often abbreviated as DEM, is a colorless, sweet-smelling ester used extensively in organic synthesis. It's a key intermediate in the malonic ester synthesis, a process for creating substituted acetic acids. The molecule's active methylene group, located between two carbonyl groups, makes the hydrogen atoms acidic, allowing for easy deprotonation. This property makes it a versatile building block for pharmaceuticals, fragrances, and other fine chemicals.

Setting up a diethylmalonate production plant, you'd need a reaction vessel, a condenser, and distillation columns. The primary reactants are malonic acid or a malonate salt and ethanol. The process involves reacting malonic acid with an excess of ethanol in the presence of a strong acid catalyst, such as sulfuric acid. After the reaction, the mixture is neutralized and then purified through distillation to separate the diethylmalonate from unreacted starting materials and by-products. This setup is relatively straightforward for batch or continuous production.

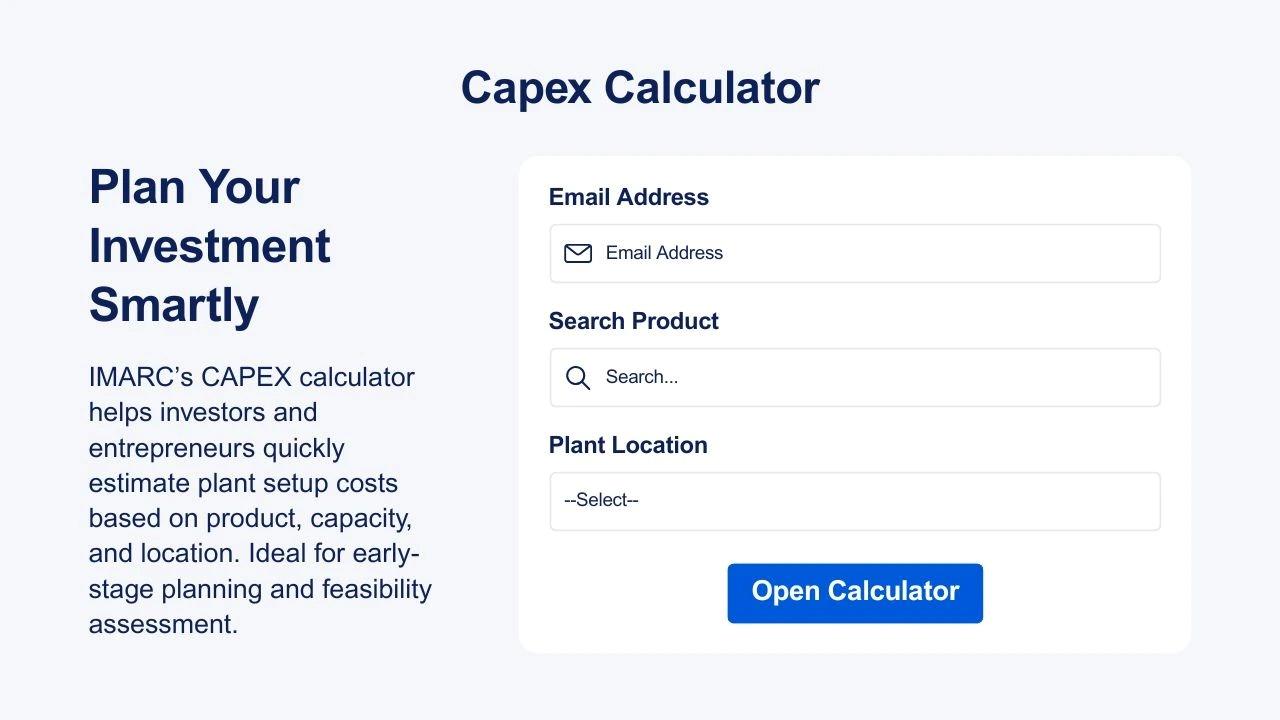

IMARC Group's report, titled “Diethylmalonate Production Cost Analysis 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue,” provides a complete roadmap for setting up a diethylmalonate production plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Request for a Sample Report: https://www.imarcgroup.com/diethylmalonate-manufacturing-plant-project-report/requestsample

Diethylmalonate Industry Outlook 2025

The diethylmalonate (DEM) industry is poised for significant growth in 2025, driven by its versatile applications, particularly in the pharmaceutical and agrochemical sectors. As a crucial intermediate for synthesizing various drugs and pesticides, the rising global demand for healthcare and agricultural products is fueling market expansion. Additionally, DEM's use in the flavors and fragrances industry further contributes to its positive outlook, particularly in regions like Asia-Pacific, which is a dominant market for both production and consumption. However, challenges such as stringent environmental regulations and fluctuating raw material costs may impact profitability and growth.

Key Insights for Diethylmalonate Production Plant Setup

Detailed Process Flow

-

Product Overview

Unit Operations Involved

Mass Balance and Raw Material Requirements

Quality Assurance Criteria

Technical Tests

Project Details, Requirements, and Costs Involved:

-

Land, Location and Site Development

Plant Layout

Machinery Requirements and Costs

Raw Material Requirements and Costs

Packaging Requirements and Costs

Transportation Requirements and Costs

Utility Requirements and Costs

Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

-

Capital Investments

Operating Costs

Expenditure Projections

Revenue Projections

Taxation and Depreciation

Profit Projections

Financial Analysis

Profitability Analysis:

-

Total Income

Total Expenditure

Gross Profit

Gross Margin

Net Profit

Net Margin

Request for Customization: https://www.imarcgroup.com/request?type=report&id=10719&flag=E

Key Cost Components of Setting Up a Diethylmalonate Plant

-

Capital Expenditures: This is the biggest initial investment. It includes land and site development, machinery and equipment (reactors, distillation columns, etc.), and civil works for plant infrastructure.

Raw Materials: A major operating expense. This involves the continuous cost of acquiring necessary chemicals, such as chloroacetic acid, sodium carbonate, and ethanol.

Utilities: The ongoing cost of essential services. This covers electricity for machinery, water for various processes, and steam for heating.

Labor and Staffing: The costs associated with hiring and training personnel, including operators, engineers, and administrative staff.

Economic Trends Influencing Diethylmalonate Plant Setup Costs 2025

-

Rising Raw Material Costs : Prices for feedstocks like diethyl malonate and other key chemicals are expected to rise due to market demand from the pharmaceutical, fragrance, and agrochemical industries.

Increasing Construction and Labor Costs : Chemical plant construction and labor costs are predicted to increase due to inflation, material shortages, and growing wages in the sector.

Geopolitical and Supply Chain Volatility : Ongoing trade tensions and supply chain disruptions can increase transportation costs and create uncertainty in sourcing materials, directly impacting project budgets.

Regulatory Compliance and Green Initiatives : Stricter environmental regulations and a global push for sustainable manufacturing will necessitate investments in cleaner technologies, which can raise initial setup costs.

Government Incentives : Countries like India are offering subsidies and other support through initiatives such as“Make in India” to boost domestic chemical manufacturing, which can help offset some of these costs.

Challenges and Considerations for Investors

-

Market Volatility : Prices for raw materials, such as malonic acid and ethanol, can fluctuate, impacting production costs and profitability.

Regulatory Compliance : The chemical industry is subject to strict environmental and safety regulations. Investors must account for the costs and risks associated with compliance, particularly regarding waste disposal and eco-friendly production methods.

Competition and Demand : The market is driven primarily by the pharmaceutical, agrochemical, and fragrance industries. Intense competition and shifts in demand from these sectors can influence market growth.

Technological Advancements : Traditional production methods create a lot of waste and environmental pollution. Investing in R&D for greener, more efficient production technologies is vital for long-term competitiveness.

Environmental and Health Risks : Diethyl malonate can be a health hazard if not handled properly. There are also environmental risks to consider, as it's harmful to aquatic life.

Conclusion

This report aims to serve as a practical guide for entrepreneurs, investors, and industrial planners exploring opportunities in diethylmalonate production. By understanding the cost structure, market dynamics, and operational challenges, stakeholders can make informed decisions and devise sustainable strategies for entry and expansion in the sector.

About Us: IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St., Brooklyn, NY 11249, USA

Email:

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment