(MENAFN- Robotics & Automation News) The Hidden Heroes of PCB Production: A Closer Look at Gerber Files

June 16, 2023 by mark allinson leave a comment

1. The Power of Gerber Files in PCB Manufacturing: A Comprehensive Guide

Gerber Files' Evolution in PCB Manufacturing

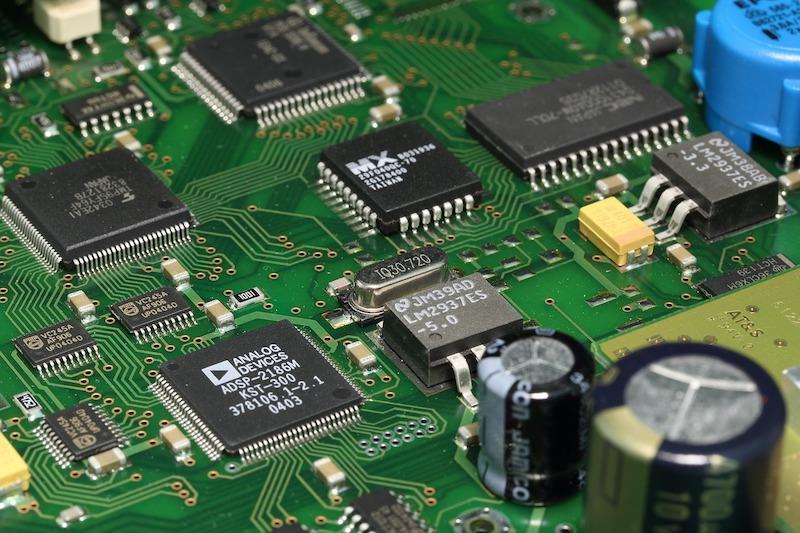

In the world of PCB manufacturing, gerber files have played a crucial role in streamlining the production process.

Over the years, these files have evolved to become more sophisticated and efficient, allowing manufacturers to create high-quality PCBs with greater speed and accuracy.

Gerber Files: Unsung PCB Design Heroes

While PCB designers may get all the credit for creating innovative circuit board layouts, it's the Gerber files that bring those designs to life.

These files provide the manufacturer with all the necessary information to produce a reliable, functional PCB. Without Gerber files, the design process would be incomplete and manufacturing would be much more difficult.

Gerber Files for Reliable, High-Quality PCBs

When it comes to PCB manufacturing, reliability and quality are crucial. Gerber files enable manufacturers to produce PCBs that meet or exceed these standards.

By providing detailed information on the design, layout, and specifications, Gerber files ensure that the final product is accurate, functional, and built to last.

With the help of Gerber files, manufacturers can create PCBs that meet the demands of the most challenging applications.

2. Maximizing PCB Production Efficiency with Gerber Files: What You Need to Know

Gerber Files: Efficient and Error-Free PCB Manufacturing

Gerber files have become the industry standard for creating PCBs due to their efficiency and accuracy. By providing detailed information on the design, including the layout, components, and other specifications, Gerber files ensure that the final product is error-free and meets all requirements.

With the help of Gerber files, manufacturers can streamline the manufacturing process and produce high-quality PCBs with ease.

Gerber Files vs. Other PCB Design Tools

While there are many tools available for designing PCBs, Gerber files offer several distinct advantages. Unlike other tools, Gerber files provide a standardized format that can be easily shared between designers and manufacturers.

They also offer greater precision and accuracy, ensuring that the final product meets all specifications. With their efficiency and reliability, Gerber files have become the preferred choice for PCB design.

Creating Flawless Gerber Files for PCB Manufacturing

Creating Gerber files that are error-free and accurate requires a deep understanding of the PCB design process and the manufacturing requirements.

Designers must carefully consider all aspects of the design, including the layout, trace widths, and component placement, to ensure that the final product is reliable and high-quality.

With the right tools and expertise, however, it's possible to create flawless Gerber files that streamline the manufacturing process and produce exceptional PCBs.

3. Gerber Files: The Key to Accurate and Cost-Effective PCB Manufacturing

Accurate Gerber Files for Vital PCB Manufacturing

Accurate Gerber files are essential for successful PCB manufacturing. These files provide manufacturers with the precise layout, dimensions, and other specifications needed to produce a reliable and functional circuit board.

With the help of Gerber files, manufacturers can ensure that their products meet all requirements and perform as intended.

Gerber Files Facilitating PCB Manufacturing

Gerber files are a critical tool for facilitating PCB manufacturing. They provide manufacturers with the information they need to build a high-quality product quickly and efficiently.

By using Gerber files, manufacturers can streamline the manufacturing process, reduce errors, and produce reliable, functional PCBs.

Gerber Files: The Backbone of Successful PCB Design

Successful PCB design relies on accurate and detailed Gerber files. These files serve as the backbone of the design process, providing designers with the information they need to create a functional and reliable circuit board.

With the help of Gerber files, designers can ensure that their PCBs meet all requirements and perform as intended. The precision and accuracy of Gerber files are key to the success of any PCB design project.

4. From Design to Production: How Gerber Files Are Revolutionizing PCB Manufacturing

Gerber Files: Ultimate Tool for Streamlining PCB Manufacturing

Gerber files are the ultimate tool for streamlining PCB manufacturing. They provide manufacturers with the precise information they need to produce high-quality circuit boards quickly and efficiently.

With Gerber files, manufacturers can reduce errors, minimize waste, and optimize the manufacturing process for maximum efficiency.

Benefits of Using Gerber Files for Cost-Effective PCB Production

Using Gerber files for PCB production offers several cost-saving benefits. By providing accurate design information, Gerber files reduce the risk of manufacturing errors that can result in wasted materials and time-consuming rework.

Additionally, Gerber files make it possible to produce PCBs with greater speed and efficiency, reducing manufacturing costs and improving overall profitability.

Comprehensive Guide to Optimizing PCB Design with Gerber Files

Optimizing PCB design with Gerber files requires a comprehensive understanding of the design process and the manufacturing requirements.

This guide provides an overview of the key considerations for creating high-quality Gerber files, including trace widths, component placement, and layer stacking.

By following these guidelines, designers can create Gerber files that optimize the manufacturing process and produce reliable, functional PCBs.

5. A Deep Dive into Gerber Files: The Foundation of Successful PCB Design and Manufacturing

The Future of Gerber Files in PCB Manufacturing

As PCB technology continues to evolve, Gerber files are likely to remain a critical tool for PCB manufacturing. However, as new design tools and manufacturing processes emerge, it's possible that Gerber files will need to adapt to remain relevant.

This article explores the future of Gerber files in PCB manufacturing and what changes we might expect to see in the coming years.

Gerber Files vs. Other Design Formats

When it comes to PCB design, there are several different file formats to choose from. However, Gerber files have become the industry standard due to their accuracy and efficiency.

In this article, we compare Gerber files to other design formats and explore the pros and cons of each. By understanding the strengths and weaknesses of each format, designers can choose the best option for their specific needs.

Advancements in Gerber Files and the Future of PCB Manufacturing

As PCB technology advances, so too do the tools and methods used to create and manufacture circuit boards. This article explores some of the recent advancements in Gerber files and how they are impacting PCB manufacturing.

From improved accuracy to greater efficiency, these advancements are helping to shape the future of PCB manufacturing and make it easier than ever to produce high-quality circuit boards.

This piece of writing discussed the significance of Gerber files in the PCB manufacturing process. Gerber files play a crucial role in providing manufacturers with precise information on the design, layout, and specifications of a circuit board, enabling them to produce high-quality PCBs efficiently.

The piece covered various topics related to Gerber files, such as their evolution, benefits over other design formats, and how they streamline the manufacturing process.

It also emphasized the importance of creating accurate Gerber files to produce reliable and high-quality PCBs. Furthermore, the text explored recent advancements in Gerber files and their impact on the future of PCB manufacturing.

As PCB technology continues to evolve, Gerber files are expected to remain a crucial tool, but they may need to adapt to new design tools and manufacturing processes.

Overall, this text highlighted the importance of Gerber files in PCB manufacturing and their role in producing reliable and high-quality circuit boards.

Comments

No comment