Auralia Metallurgy Commences Flotation Test Work Optimisation Program For The Ashram REE And Fluorspar Project, Quebec

- Mont Royal has recommenced metallurgical flotation test work on the Ashram Project, with highly regarded rare earth flotation specialists Auralia Metallurgy Pty Ltd (Auralia) engaged to undertake the program.

A ~700kg bulk sample of mineralised material from Ashram has already arrived in Australia and has been expedited for analysis by Auralia. This work will build on the excellent results achieved from the previous SGS Lakefield campaign which provided high-grade rare earth mineral concentrate of 36% REO.

The program will further evaluate the potential to produce a commercial fluorspar (CaF 2 ) concentrate and incorporate this potential high-value by-product opportunity into the Stage 1 flowsheet. It will also produce additional concentrate both for further Hydromet test work optimisation and to undertake test work utilising new and alternative processing technology groups.

Mont Royal's Managing Director, Nicholas Holthouse, said: "We are very pleased to see this important work now underway, with momentum building towards de-risking the technical aspects of the Ashram Project and progressing through the study phases.

"The flotation concentrate generated from this program will increase our confidence in what is already a robust flowsheet for the Preliminary Economic Assessment and Pre-Feasibility Studies. The potential addition of a fluorspar product to the Ashram economics would be a positive step forward and a welcome addition to the project's economics.

"We will also explore the opportunity to use new processing technologies now available in the market, with a portion of the concentrate to be allocated to potential new technology partners.

"We are delighted to have Auralia on board as a technical partner as we take the Ashram Project forward."

Vancouver, British Columbia--(Newsfile Corp. - December 1, 2025) - Mont Royal Resources Ltd (ASX: MRZ) (TSXV: MRZL) (" Mont Royal " or " the Company ") is pleased to announce the recommencement of key metallurgical test work programs as part of its strategy to rapidly advance the development of the 100%- owned Ashram REE and Fluorspar Project in Northern Quebec, Canada.

Mont Royal has engaged highly regarded rare earth flotation specialists Auralia Metallurgy Pty Ltd to assist with further refinement of the existing flowsheet, building on historical test work from SGS Lakefield that has already produced outstanding results utilising a new and representative bulk sample from the Ashram deposit.

PREVIOUS WORK

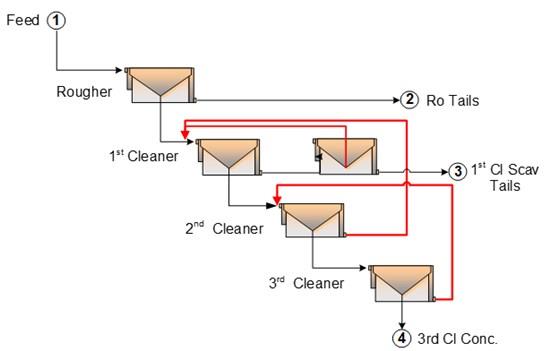

As previously reported, the locked-cycle test ("LCT") program was completed on the Ashram Deposit's simplified flotation-only beneficiation flowsheet, demonstrating significantly improved grade and recovery metrics compared to the prior bench-scale test programs.

This breakthrough in flotation effectively targets the monazite and bastnasite rare earth host minerals, producing concentrates grading 35.8-36.8% REO at an overall recovery of 65-68%.

These results were achieved through the LCT tests carried out by SGS Canada at their Lakefield, ON, facility utilising bulk sample material (~2.1% REO head grade) collected from an outcrop of the Ashram Deposit.

Figure 1: The flotation locked-cycle test flowsheet. Each cycle consisted of a rougher flotation stage, three (3) cleaner flotation stages, and a 1st cleaner-scavenger stage. The three streams shown in red were recirculated from one cycle to the next (e.g., the 3rd cleaner concentrate from cycle A was fed to the 2nd cleaner of Cycle B).

To view an enhanced version of this graphic, please visit:

Figure 2: Flotation of Ashram whole rock sample material in a 2-litre Denver cell.

To view an enhanced version of this graphic, please visit:

Figure 3: Combined final locked-cycle test high-grade (>35% REO) rare earth flotation mineral concentrate.

To view an enhanced version of this graphic, please visit:

AURALIA METALLURGICAL TESTWORK SCOPE

Sample preparation

This will be undertaken for both sighter and bulk test work programs. Crushing and blending will be undertaken followed by head assay assessment through conventional assay and XRD analysis. Samples will then be ground in preparation for the flotation test work stage.

REE Flotation Test Work

Test work will be undertaken in multiple batches starting with 1kg 3-stage cleaner tests followed by multiple 20kg bulk tests processing up to 400kg of sample material. Floated concentrate will be assayed for all recovered REEs along with associated multi-element and impurities analysis. All batched concentrates will then be blended and assayed for final use in further downstream programs.

Fluorspar Flotation Test Work

Flotation test work will be undertaken on the REE flotation tailings stream to further verify and optimise previous work undertaken targeting saleable fluorspar products.

A metallurgical grade fluorspar (metspar) product (+65% CaF2) is targeted initially. The viability of producing a higher grade acidspar (+94% CaF2) product will also be investigated, noting that a saleable acidspar product has been previously produced by the Company.

Figure 4: Ashram Acidspar flotation concentrate.

To view an enhanced version of this graphic, please visit:

NEXT STEPS

REE Flotation

Variability testing and pilot plant testing programs for REE's will be required for the Pre-Feasibility Study targeted to commence in Q3 2026.

Fluorspar Flotation

In addition to REE flotation and following the positive LCT results already achieved which have confirmed the robustness of the flotation-only beneficiation flowsheet, the Company will continue to progress a program to evaluate fluorite recovery from the rare earth mineral concentrate tailings.

The Company has already demonstrated the ability to produce a saleable acidspar product (see Figure 4). The inclusion of a fluorspar recovery circuit in the initial Ashram development stage would be a significant benefit to project economics.

Fluorspar (CaF2) is recognized as a critical/strategic mineral by Canada, Europe, Japan, and the United States, and is also a key input into lithium-ion batteries.

Hydromet Test Work

Additional optimisation work around the sulphation bake process will be required for the PFS work package. The Company is progressing discussions with specialist test work providers and will be utilising flotation concentrate from the Auralia program to undertake this work.

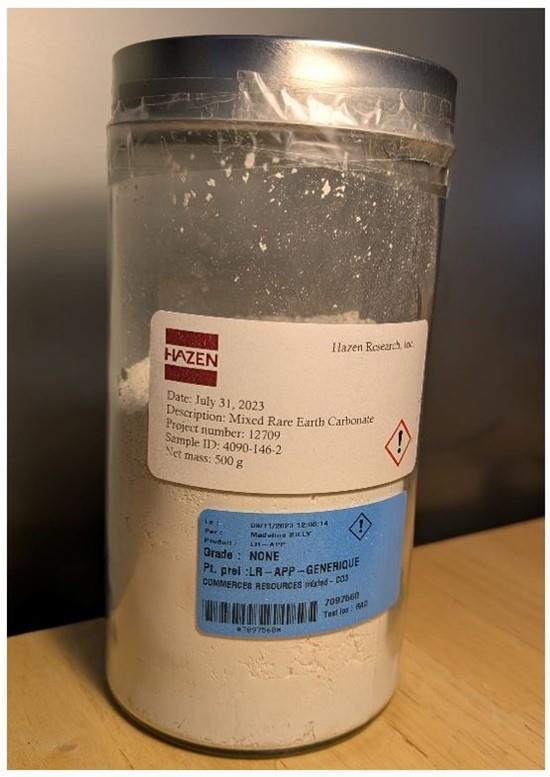

As noted above, the Ashram Project has already demonstrated the ability to produce a clean, marketable mixed rare earth carbonate (MREC), with a sample shown below in Figure 5.

Figure 5: Ashram Mixed Rare Earth Concentrate (MREC).

To view an enhanced version of this graphic, please visit:

New Technologies

While the Ashram Project already has a robust flotation and hydromet flowsheet and has demonstrated the ability to produce a clean and saleable MREC product, new and emerging technologies may provide opportunities beyond the flotation stage.

Discussions are underway with technology groups which may offer alternatives to the standard flowsheet, and a portion of the generated samples will be made available for programs in 2026 with these groups.

KEY ASSETS AND STRATEGY

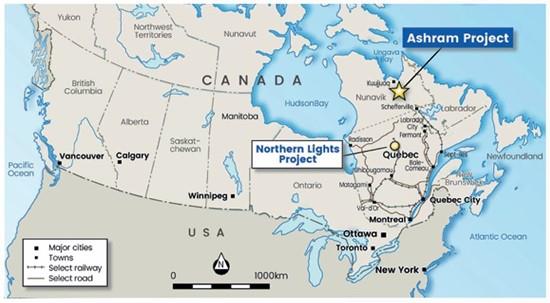

The merged Company's flagship asset is the 100%-owned Ashram Rare Earths & Fluorspar Project ("Ashram Project"), which represents the largest undeveloped monazite-mineralised carbonatite-hosted Rare Earth Elements deposits in North America. In addition, the Company also holds the Eldor Niobium Project and the Northern Lights Lithium Project, both also located in Québec (see Figure 1 below).

The Ashram Project is a Tier-1 REE deposit with high-value by-product potential (Fluorspar) and represents one of the most advanced rare earth development projects in North America. With over A$50 million invested historically in exploration, drilling, resource definition and development studies, Ashram represents a cornerstone asset in Canada's critical minerals push.

Figure 6: Ashram REE & Fluorspar Project Location and location of Northern Lights Project.

To view an enhanced version of this graphic, please visit:

For and on behalf of the Board

ENDS

Joel Ives | Company Secretary

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment