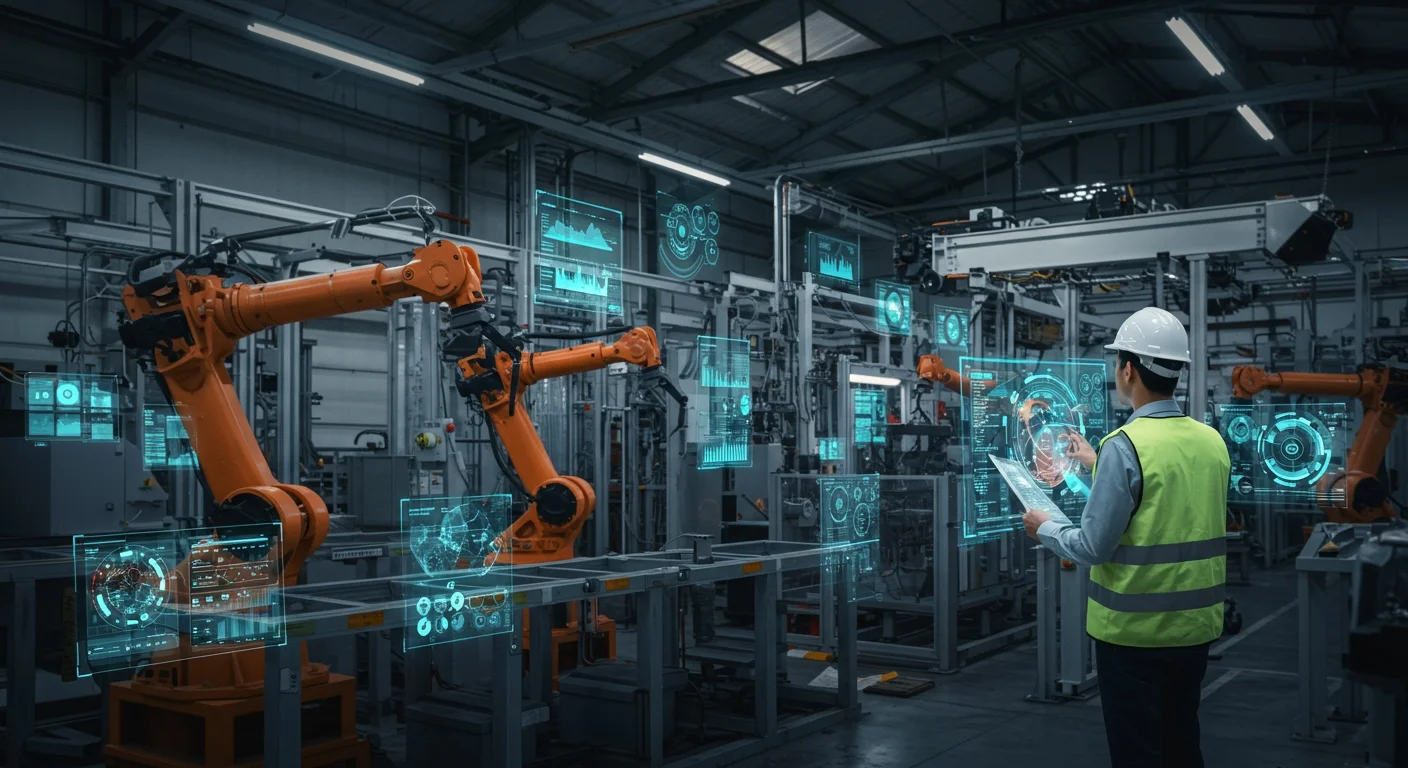

(MENAFN- AIIEM) Industrial Engineering in Smart Manufacturing: 5 Critical Insights for the Modern EraThe landscape of manufacturing is undergoing a profound transformation, driven by digital innovation and interconnected systems. At the heart of this revolution is the crucial role of Industrial Engineering in Smart Manufacturing . This synergy represents a paradigm shift from traditional production lines to intelligent, adaptive, and highly efficient factories. Industrial engineers, with their expertise in optimizing complex systems, are uniquely positioned to design, implement, and manage the integrated processes that define the smart factory.

Table of Contents What is Industrial Engineering in Smart Manufacturing? Key Pillars of Smart Manufacturing Driven by Industrial Engineering The Role of Industrial Engineers Future Trends and Challenges Overcoming Challenges and Embracing Innovation

What is Industrial Engineering in Smart Manufacturing? Industrial Engineering in Smart Manufacturing bridges the gap between theoretical models and practical applications within the context of Industry 4.0. It involves applying engineering principles to design, improve, and install integrated systems of people, materials, information, equipment, and energy. In smart manufacturing, this extends to leveraging advanced technologies like IoT, AI, big data, robotics, and cloud computing to create highly optimized and self-regulating production environments. The goal is to achieve unprecedented levels of productivity, quality, and flexibility.

Key Pillars of Smart Manufacturing Driven by Industrial EngineeringProcess Optimization and AutomationIndustrial engineers are crucial in analyzing existing manufacturing processes to identify bottlenecks and inefficiencies. In a smart factory, this analysis is enhanced by real-time data from interconnected machines. They design and implement advanced automation solutions, from collaborative robots (cobots) to fully autonomous production lines, ensuring seamless flow and reduced human intervention where appropriate. Their work involves simulating new layouts, optimizing material handling, and designing efficient work cells.

Data Analytics and Predictive MaintenanceThe deluge of data generated by smart sensors and IoT devices is a goldmine for industrial engineers. They apply statistical analysis and machine learning techniques to extract actionable insights, predicting equipment failures (predictive maintenance), optimizing energy consumption, and improving quality control. This data-driven approach allows for proactive decision-making, minimizing downtime and maximizing resource utilization.

Supply Chain IntegrationSmart manufacturing extends beyond the factory floor, encompassing the entire supply chain. Industrial engineers design integrated systems that connect suppliers, manufacturers, and customers, fostering transparency and responsiveness. They optimize logistics, inventory management, and distribution networks, often utilizing digital twins and blockchain technologies to create resilient and agile supply chains capable of responding to market fluctuations.

The Role of Industrial EngineersIndustrial engineers are the architects of efficiency in the smart manufacturing ecosystem. They are problem-solvers who combine technical expertise with a holistic understanding of business operations. Their responsibilities include:

System design and integration Performance measurement and analytics Ergonomics and workplace safety Quality management Lean and Six Sigma implementation Technology adoption and change management

They translate complex technological capabilities into practical, implementable solutions that deliver tangible business value. The table below highlights how their role has evolved.

| Aspect | Traditional IE Role | Smart Manufacturing IE Role |

| Focus Area | Manual processes, batch production | Automated, interconnected systems, real-time data |

| Tools Used | Stopwatches, flowcharts, manual data | IoT, AI, digital twins, advanced analytics software |

| Problem Solving | Reactive, efficiency gains via simplification | Proactive, predictive, holistic system optimization |

| Scope | Factory floor, specific departments | Entire value chain, cross-functional integration |

Future Trends and Challenges

The future of industrial engineering in smart manufacturing is dynamic, with emerging trends shaping its trajectory. The rise of AI-powered decision-making, advanced robotics, and hyper-personalization will demand even greater adaptability from industrial engineers. They must continuously update their skills to navigate challenges such as cybersecurity risks, data privacy concerns, and the need for a highly skilled workforce. Embracing lifelong learning and interdisciplinary collaboration will be key to success. For more insights into these developments, you can visit the Industrial IoT Solutions Group .

Overcoming Challenges and Embracing Innovation

Successfully integrating industrial engineering principles into smart manufacturing requires a strategic approach. Companies must invest in training their workforce, fostering a culture of continuous improvement, and adopting agile methodologies. Industrial engineers will be instrumental in leading these transformation efforts, ensuring that technological advancements translate into sustainable competitive advantages. This evolution is vital for businesses to thrive in the era of Industry 4.0. To learn more about the broader implications of this shift, explore our article on Understanding Industry 4.0 .

Conclusion

The symbiotic relationship between Industrial Engineering in Smart Manufacturing is not merely an evolutionary step but a revolutionary leap. Industrial engineers are the linchpins, transforming intelligent technologies into tangible operational excellence. Their expertise ensures that smart factories are not just technologically advanced but also efficiently designed, resilient, and continuously optimized, paving the way for a new era of global production.

MENAFN30092025008385017602ID1110131714

Comments

No comment