K 2025: Which Innovative Ideas Will Lead To The Next Generation Of Polymer Solutions?

Every three years, the global plastics and rubber industry comes together in Düsseldorf for K – the world's most prominent trade fair dedicated to plastics and rubber. This event serves not only as an exhibition but as a pivotal moment for reflection and collaboration, showcasing how innovative materials, technologies, and ideas are reshaping the industry.

K 2025 is set to take place from October 8 to 15, 2025, at the Messe Düsseldorf exhibition center in Germany. As celebrated internationally as the premier platform for groundbreaking innovations in the plastics and rubber sectors. K 2025 invites professionals from a wide range of industries, including manufacturing, automotive, electronics, medical technology, packaging, and construction, to come together and explore new possibilities.

Emphasizing the theme“The Power of Plastics – Green, Smart, Responsible,” K 2025 underscores the industry's dedication to sustainability, digital advancements, and responsible resource management. The event will highlight state-of-the-art technologies related to the circular economy, climate protection, artificial intelligence, and Industry 4.0, creating a valuable opportunity to examine how materials and processes have progressed over the last three years.

For engineers, R&D specialists, and procurement decision-makers looking for innovative polymer solutions, silicone processing aids, or sustainable elastomers, K 2025 provides an excellent opportunity to discover advancements that not only improve product performance but also support environmentally conscious practices. This is a chance to be part of a dialogue that will shape the future of the industry.

Key Highlights of K Show 2025

Scale and Participation: The fair is expected to host over 3,000 exhibitors from around 60 countries and attract approximately 232,000 trade visitors, with a significant portion (71% in 2022) coming from abroad. It will feature a wide range of products, including machinery, equipment, raw materials, auxiliaries, and recycling technologies.

Special Features : U.S. Pavilions: Organized by Messe Düsseldorf North America and supported by the PLASTICS Industry Association, these pavilions offer turnkey booth solutions for exhibitors.

Special Shows and Zones : The event includes the Plastics Shape the Future show, focusing on sustainability and competitiveness, the Rubber Street, Science Campus, and Start-up Zone to highlight innovations and emerging companies.

K-Alliance : Messe Düsseldorf has rebranded its global plastics and rubber portfolio as K-Alliance, emphasizing strategic partnerships and expanding its network of trade fairs worldwide.

Innovations and Trends : The fair will showcase advancements in plastics processing, recycling, and sustainable materials. For example, WACKER will demonstrate ELASTOSIL® eco LR 5003, a resource-saving liquid silicone rubber for food applications, produced using biomethanol.

....

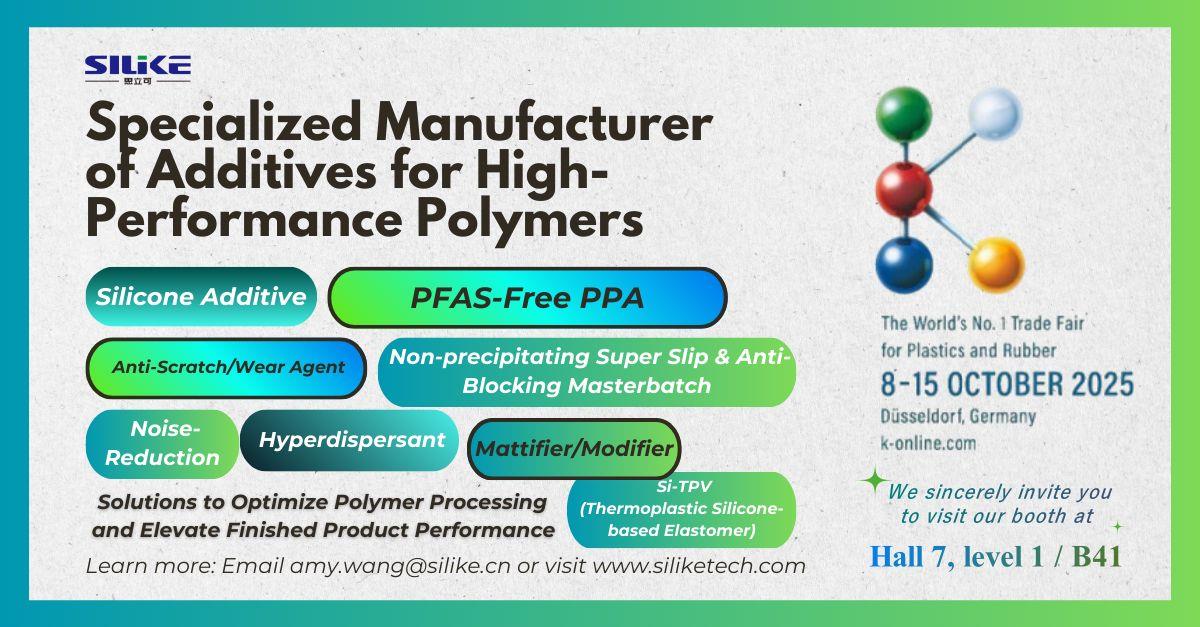

SILIKE at K Fair 2025: Empowering New Value for Plastics, Rubber, and Polymer.

At SILIKE, our mission is to empower plastics and rubber applications across industries through innovative silicone technology. Over the years, we have developed a comprehensive portfolio of plastic additives designed to enhance performance across a wide range of applications. Our solutions address key challenges, including wear resistance, scratch resistance, lubrication, slip resistance, anti-blocking, superior dispersion, noise reduction (anti-squeak), and fluorine-free alternatives.

SILIKE silicone-based solutions help boost polymer processing efficiency, enhance productivity, and improve the surface quality of finished products.

Our newly designed booth will showcase a wide range of specialty silicone additives and polymer solutions, including:

Silicone Additives

. Enhance processing and surface quality

. Improve lubricity and resin flowability

. Reduce screw slippage and die buildup

. Enhance demolding and filling capacity

. Boost productivity and lower overall costs

. Reduce friction coefficient & improve surface smoothness

. Provide abrasion & scratch resistance, extending service life

Applications: Wire & cables, engineering plastics, telecom pipes, automotive interiors, injection molds, footwear, thermoplastic elastomers.

Fluorine-Free PPA (PFAS-Free Polymer Processing Aids)

. Eco-Friendly | Eliminate Melt Fracture

. Reduce melt viscosity; improve internal & external lubrication

. Lower extrusion torque and pressure

. Minimize die buildup & increase output

. Extend equipment cleaning cycles; reduce downtime

. Eliminate melt fracture for flawless surfaces

. 100% fluorine-free, compliant with global regulations

Applications: Films, wires & cables, pipes, monofilaments, sheets, petrochemicals

Novel Modified Silicone Non-precipitating Plastic Film Slip & Anti-Blocking Agents

. Non-Migrating | Stable COF | Consistent Performance

. No blooming or bleeding; excellent heat resistance

. Provide a stable, consistent coefficient of friction

. Deliver permanent slip and anti-blocking effects without affecting printability or sealability

. Excellent compatibility with no impact on haze or storage stability

Applications: BOPP/CPP/PE, TPU/EVA films, cast films, extrusion coatings

Silicone Hyperdispersants

. Ultra-Dispersion | Synergistic Flame Retardancy

. Enhance compatibility of pigments, fillers, and functional powders with resin systems

. Improve the stable dispersion of powders

. Reduce melt viscosity and extrusion pressure

. Enhance processing and surface feel

. Provide synergistic flame-retardant effects

Applications: TPEs, TPUs, masterbatches (color/flame-retardant), pigment concentrates, highly loaded pre-dispersed formulations

Beyond Siloxane-based Additives: Innovation Sustainable Polymer Solutions

SILIKE also offers:

Silicone wax SILIMER Series Copolysiloxane Additives and Modifiers: can enhance the processing of PE, PP, PET, PC, ABS, PS, PMMA, PC/ABS, TPE, TPU, TPV, etc., while modifying their surface properties, achieving the desired performance with a small dosage.

Biodegradable Polymer Additives: Supporting global sustainability initiatives and environmentally responsible innovation, applicable to PLA, PCL, PBAT, and other biodegradable materials.

Si-TPV (Dynamic Vulcanized Thermoplastic Silicone-Based Elastomers): Deliver wear and wet-slip resistance for fashion and sports gear, providing comfort, durability, and eco-friendly processing

Ultra-Wear-Resistant Vegan Leather: A sustainable alternative for high-performance applications

By integrating SILIKE silicone-based additives, polymer modifiers, and elastomeric materials, manufacturers can achieve improved durability, aesthetics, comfort, tactile performance, safety, and sustainability

Join Us at K 2025

We warmly invite partners, customers, and industry professionals to visit SILIKE at Hall 7, Level 1 / B41.

If you are seeking plastic additives and polymer solutions that enhance performance, optimize processing, and improve end-product quality, please visit our booth to discover how SILIKE can support your innovation journey.

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Most popular stories

Market Research

- United States Lubricants Market Growth Opportunities & Share Dynamics 20252033

- Daytrading Publishes New Study On The Dangers Of AI Tools Used By Traders

- Newcastle United Announce Multi-Year Partnership With Bydfi

- Ecosync & Carboncore Launch Full Stages Refi Infrastructure Linking Carbon Credits With Web3

- Utila Triples Valuation In Six Months As Stablecoin Infrastructure Demand Triggers $22M Extension Round

- From Zero To Crypto Hero In 25 Minutes: Changelly Introduces A Free Gamified Crash Course

Comments

No comment