Solvent-Free Breakthrough: LEAD Slashes Costs 15%+ And Paves The Way For Solid-State Battery Mass Production

As a globally leading provider of intelligent manufacturing solutions for new energy, LEAD focuses on the entire solid-state battery manufacturing chain. LEAD has launched the first comprehensive all-solid-state battery production line solution in the industry, covering all critical manufacturing processes for solid-state batteries. The solution spans solid-state electrode production, solid-state electrolyte film coating and lamination equipment, cell assembly, densification equipment, and high-voltage formation and aging. LEAD's technologies offer significant advantages in electrode structure buffering, separator-free stacking, continuous densification, and high-voltage formation.

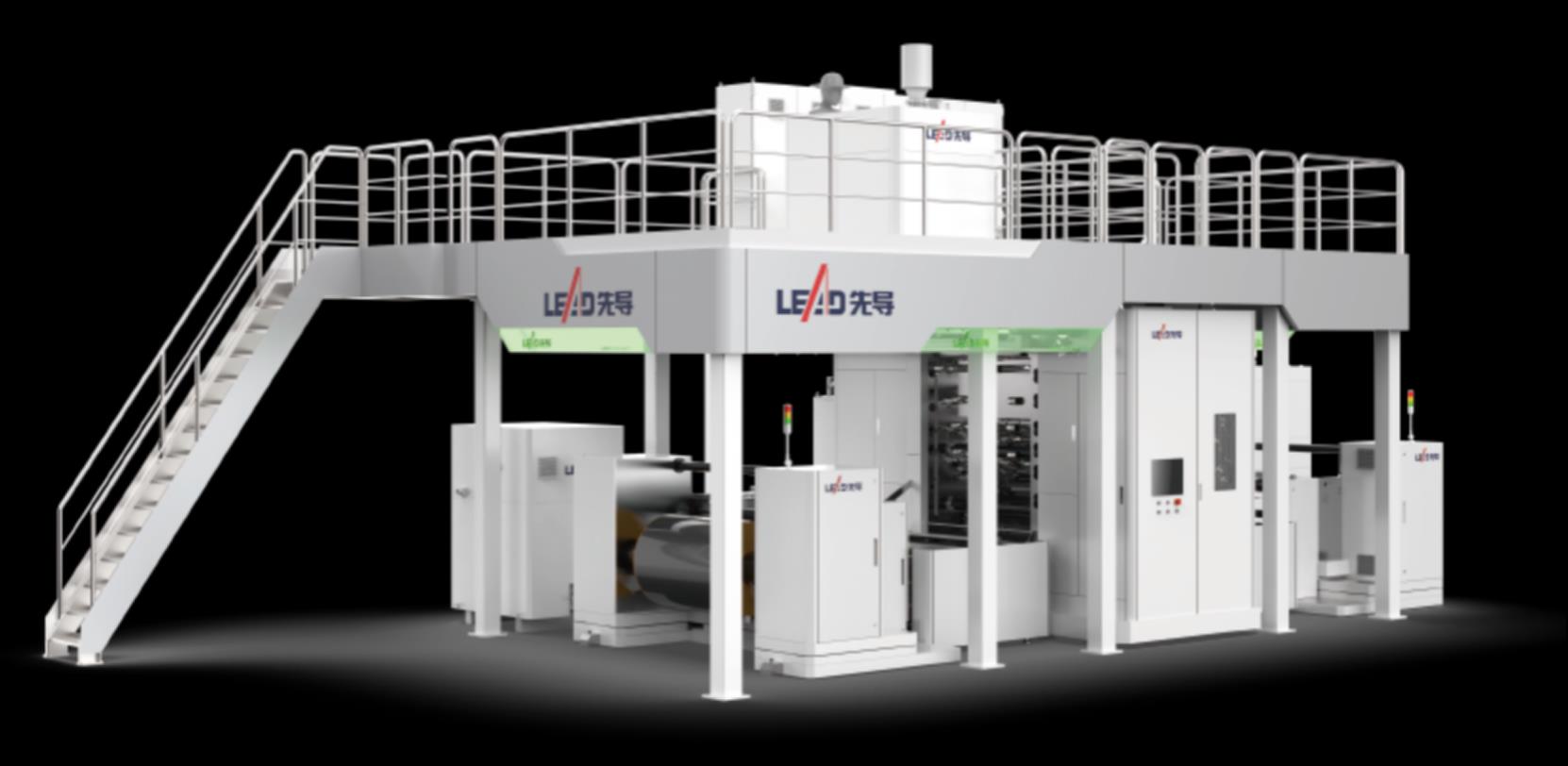

LEAD's dry electrode mixing and coating system achieves maximum mechanical speeds of 100m/min, supporting single-line production capacities of 5-8 GWh. It accommodates product widths up to 1000 mm and thicknesses ranging from 40 μm to 300 μm. The system is efficiently compatible with processing 2-6 dry electrode sheets simultaneously, delivering comprehensive scalability for large-scale manufacturing scenarios.

Field production validation demonstrates that LEAD's dry electrode mixing and coating system reduces energy consumption by over 35% and lowers combined material and manufacturing costs by more than 15%. Notably, the system precisely adapts to all-solid-state battery production while proactively maintaining compatibility with traditional liquid battery manufacturing processes. This dual-purpose flexibility enables flexible production, providing robust assurance for enterprises to reduce equipment investment and enhance capacity utilization during technological transition periods.

As one of the few global battery equipment manufacturers capable of delivering complete lithium battery production lines, LEAD has pioneered the integration of all process equipment required for mass-producing all-solid-state batteries, establishing a technology matrix with 100% independent intellectual property rights. And they have successfully delivered the dry electrode coating machine, lamination & decaling machine, electrode framing machine, high-speed stacking machine , and hundred-ton cold/hot pressing formation & aging machine along with related solutions for solid-state battery. And LEAD has successfully signed strategic cooperation agreements with several leading material companies to jointly advance solid-state electrolyte R&D and material validation on the equipment side, accelerating the industrialization process.

Media Contacts

Website:

Email: ...

Photos accompanying this announcement are available at

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment