Polypropylene Fabric Manufacturing Plant Setup Report 2025: Business Plan, Cost And Raw Material Requirements

Setting up a polypropylene fabric manufacturing plant requires selecting suitable machinery for fiber extrusion, spinning, and weaving or nonwoven production, ensuring quality control systems, securing raw polypropylene supply, and complying with environmental and safety regulations. Efficient plant layout and skilled labor are essential for optimal productivity.

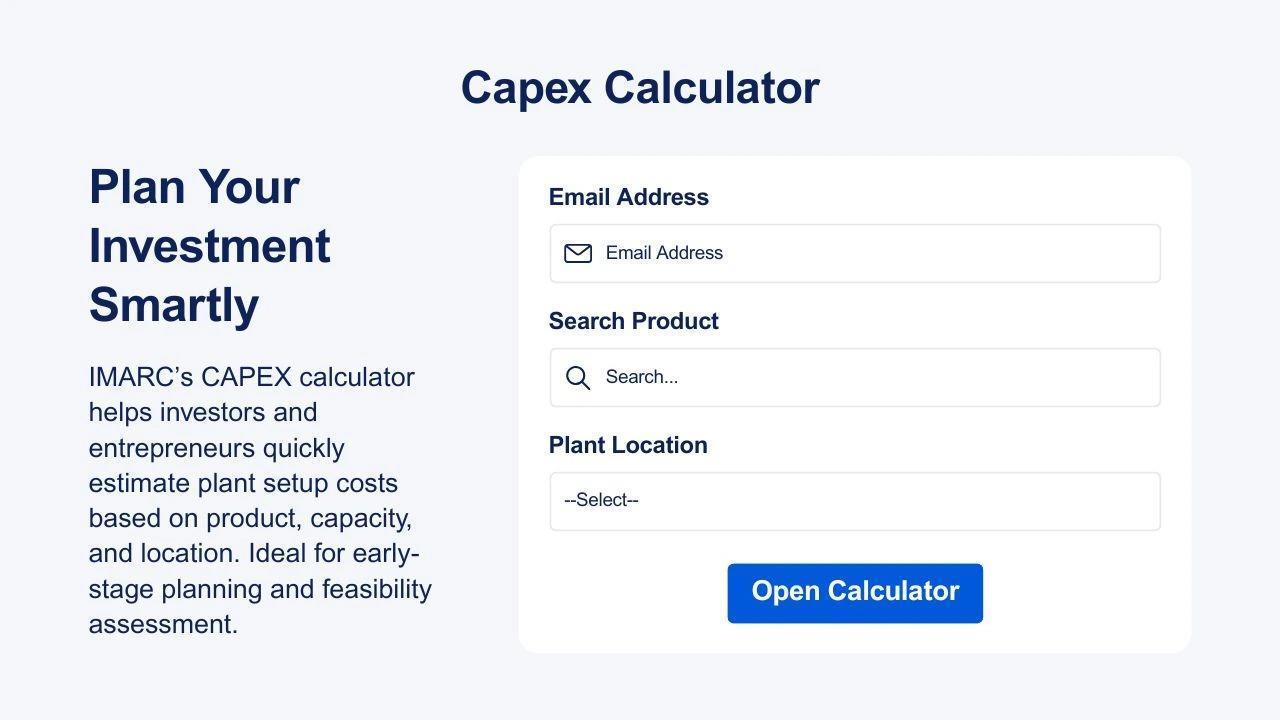

IMARC Group's report, titled “ Polypropylene Fabric Manufacturing Plant Project Report 2025: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue,” provides a complete roadmap for setting up a polypropylene fabric manufacturing plant. It covers a comprehensive market overview to micro-level information such as unit operations involved, raw material requirements, utility requirements, infrastructure requirements, machinery and technology requirements, manpower requirements, packaging requirements, transportation requirements, etc.

Request for a Sample Report : https://www.imarcgroup.com/polypropylene-fabric-manufacturing-plant-project-report/requestsample

Polypropylene Fabric Industry outlook 2025:

The polypropylene fabric industry in 2025 is expected to witness steady growth, driven by rising demand in packaging, medical textiles, automotive interiors, and geotextiles. Increasing focus on lightweight, cost-effective, and recyclable materials is boosting adoption across industries. The nonwoven polypropylene segment, in particular, is projected to expand due to continued use in hygiene products and protective equipment. Technological advancements in fiber processing and sustainable manufacturing practices are further enhancing market competitiveness. Asia-Pacific is anticipated to dominate production and consumption, supported by robust manufacturing capacity and growing industrial applications, while global trade is likely to benefit from improving supply chain stability.

Key Insights for Polypropylene fabric Manufacturing Plant Setup:

Detailed Process Flow:

-

Product Overview

Unit Operations Involved

Mass Balance and Raw Material Requirements

Quality Assurance Criteria

Technical Tests

Project Details, Requirements and Costs Involved:

-

Land, Location and Site Development

Plant Layout

Machinery Requirements and Costs

Raw Material Requirements and Costs

Packaging Requirements and Costs

Transportation Requirements and Costs

Utility Requirements and Costs

Human Resource Requirements and Costs

Capital Expenditure (CapEx) and Operational Expenditure (OpEx) Analysis:

Project Economics:

-

Capital Investments

Operating Costs

Expenditure Projections

Revenue Projections

Taxation and Depreciation

Profit Projections

Financial Analysis

Profitability Analysis:

-

Total Income

Total Expenditure

Gross Profit

Gross Margin

Net Profit

Net Margin

Key Cost Components of Setting Up a Polypropylene Fabric Plant :

-

Land and Infrastructure: Purchase or lease of industrial land, construction of production halls, warehouses, and administrative offices.

Machinery and Equipment: Investment in extrusion lines, spinning machines, weaving or nonwoven production units, and finishing systems.

Raw Materials: Procurement of polypropylene granules and additives required for fabric production.

Utilities: Installation and ongoing costs for electricity, water supply, compressed air, and waste management systems.

Labor Costs: Salaries for skilled and unskilled workers, engineers, and administrative staff.

Quality Control and Testing Facilities: Equipment for fabric inspection, strength testing, and compliance verification.

Licensing and Regulatory Compliance: Permits, certifications, and environmental compliance costs.

Logistics and Distribution Setup: Packaging systems, transportation arrangements, and warehouse management.

Working Capital: Funds for initial operations, procurement, and contingency reserves.

Economic Trends Influencing Polypropylene Fabric Plant Setup Costs 2025 :

-

Raw Material Price Volatility: Fluctuations in polypropylene resin prices due to changes in crude oil markets and global supply-demand dynamics.

Energy Cost Variations: Rising electricity and fuel prices impacting operational expenses and long-term plant sustainability.

Global Supply Chain Shifts: Evolving trade policies, freight costs, and port congestion affecting machinery imports and raw material availability.

Technological Advancements: Adoption of automated and energy-efficient machinery increasing upfront costs but reducing long-term production expenses.

Labor Market Conditions: Wage inflation and skilled labor shortages in manufacturing hubs influencing payroll expenditure.

Environmental Compliance Costs: Stricter sustainability regulations requiring investment in waste treatment, emission control, and recycling systems.

Currency Exchange Rate Fluctuations: Impacting the cost of importing machinery, technology, and raw materials.

Speak to an Analyst for Customized Report: https://www.imarcgroup.com/request?type=report&id=12320&flag=E

Challenges and Considerations for Investors in Polypropylene Fabric Plant Projects:

-

Market Demand Uncertainty: Fluctuating demand across sectors such as packaging, medical, and automotive due to economic or regulatory changes.

Raw Material Dependency: Reliance on polypropylene resin, which is subject to oil price volatility and supply chain disruptions.

Technological Upgradation Needs: Continuous investment in advanced machinery to maintain competitiveness and meet quality standards.

Regulatory Compliance: Adherence to environmental, safety, and industry-specific regulations, which may require costly modifications.

Capital-Intensive Setup: High initial investment with extended payback periods, requiring strong financial planning.

Competition Pressure: Price competition from established domestic and international manufacturers affecting profit margins.

Skilled Workforce Availability: Recruiting and retaining trained personnel for specialized production and quality control processes.

Conclusion:

The polypropylene fabric industry in 2025 presents substantial opportunities for growth, supported by expanding applications in packaging, healthcare, automotive, and infrastructure sectors. However, establishing a manufacturing plant requires careful consideration of capital requirements, raw material sourcing, regulatory compliance, and technological capabilities. Investors must address cost volatility, evolving environmental standards, and competitive market conditions through strategic planning and adoption of efficient production methods. With a balanced approach that combines market analysis, operational efficiency, and sustainable practices, polypropylene fabric plant projects can achieve long-term profitability and resilience in a dynamic global manufacturing landscape.

About Us:

IMARC Group is a global management consulting firm that helps the world's most ambitious changemakers to create a lasting impact. The company excel in understanding its client's business priorities and delivering tailored solutions that drive meaningful outcomes. We provide a comprehensive suite of market entry and expansion services. Our offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape, and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales[@]imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: (+1-201971-6302)

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment