403

Sorry!!

Error! We're sorry, but the page you were looking for doesn't exist.

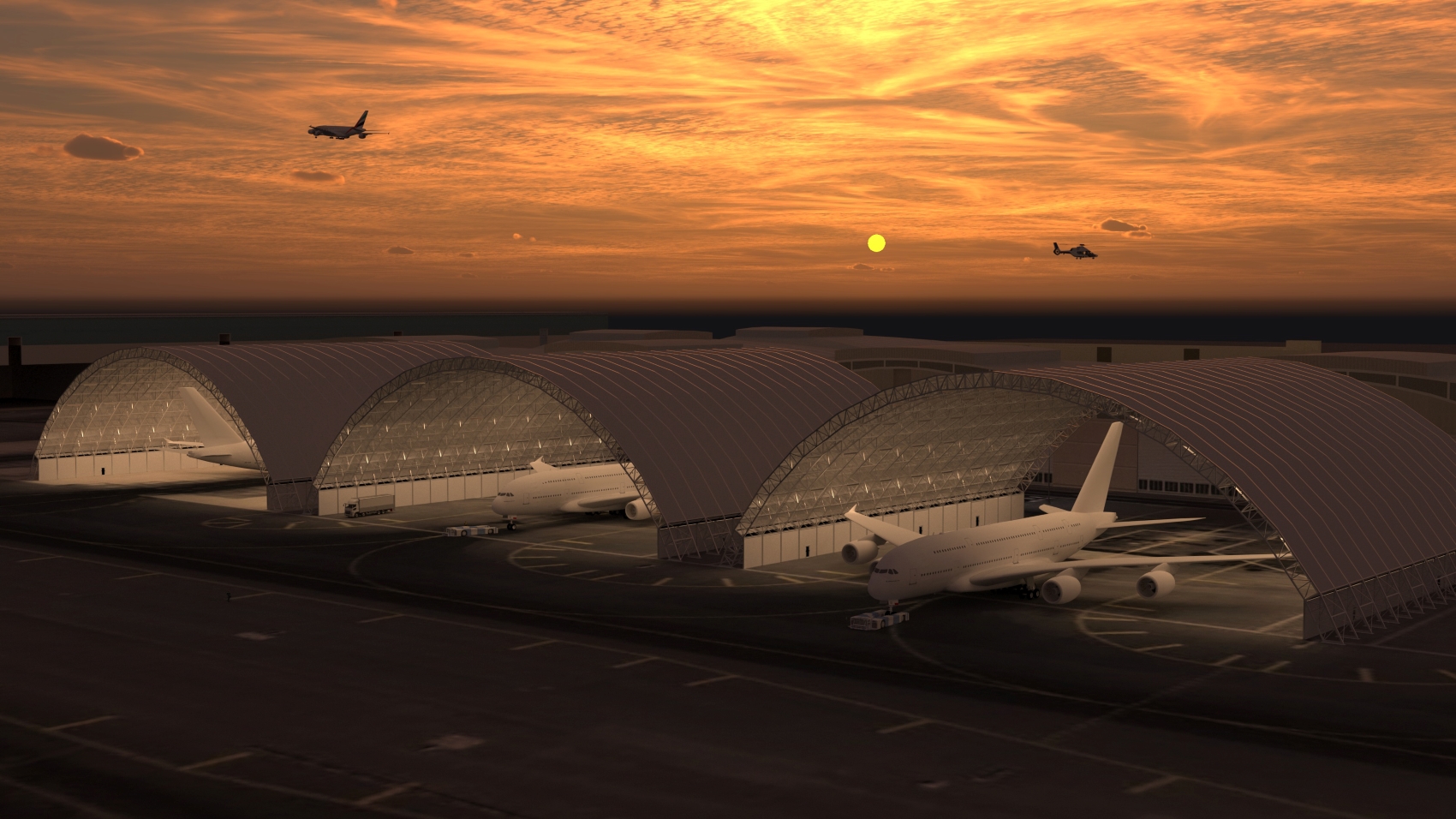

New specialised storage and maintenance hangars present solution to A380 wing-spar cracking problem

(MENAFN- IHC) Leading temporary and semi-permanent buildings specialist Losberger De Boer has announced the organisation can now provide a comprehensive hangar solution for the storage and light maintenance of A380s that will protect the aircraft from environmental factors and help prevent wing cracks.

Losberger De Boer has addressed the problem potentially delaying Airbus A380 operators’ plans to reintroduce the aircraft into their fleets following extended storage during the pandemic. Caused by extreme temperatures and moisture, hydrogen-assisted cracking or hydrogen embrittlement can accelerate the rate at which cracks can form in the A380’s wing’s aluminium alloys.

With a long history of supplying airport expansion and hangar solutions in the Middle East and Europe, Losberger De Boer now offers a new temporary structure large enough to accommodate the A380 aircraft, a new building for the space solutions specialist that is now available in the Middle East and globally for the first time. Modular by design, the 95-metre clearspan space solution represents the evolution of structures that have been used as airport and airfield terminals and hangars. The upsized hangar will be capable of shading one or more A380 aircraft. Open at both ends, the structure can be installed to ensure existing hangars remain easily accessible, providing a flexible solution for storage and light maintenance requirements.

Measuring 95 metres wide by 90 metres long, the bespoke aluminium curved framed shade structure is manufactured off-site, providing an efficient and more sustainable solution compared to traditional, on-site, permanent construction. Once transported to its final destination, the structure can be assembled quickly, meaning the hangar can be operational within as little as four months from order. Should there be a later requirement to move the structure, the hangar is fully demountable, easily stored and can be reassembled at a different location.

The hangar’s PVC roof and polyisocyanurate (PIR) sandwich panels protect the aircraft within the hangar from environmental elements. Delivered turnkey, the structure features overhead fans to cool the air. Losberger De Boer also offers a climate control system, enabling temperature and humidity levels to be set and monitored.

“Heat and humidity have been identified as leading contributing factors of the wing-spar cracking problem reported,” said Paul Machin, Losberger De Boer Middle East’s senior sales manager.

“Providing temporary and semi-permanent space solutions for aircraft owners and operators to meet environmental challenges is not new for Losberger De Boer. We have been providing hangars, industrial hangars and terminals for many years. However, the A380 presented a new challenge, and we are offering this new hangar to offer the same level of quality we are known for on a larger scale. High temperatures and humidity levels in the Middle East, combined with the need for a shaded structure to store and carry out light maintenance, prompted us to bring a solution to the market that could be manufactured and installed in months, rather than years.”

The large-scale hangar does not require traditional foundations, meaning it can be erected and handed over within six weeks following delivery. The curved frame is secured to the existing concrete platform via chemical anchoring. Once disassembled, the site can be returned to its previous state with no need for any rectification works.

Losberger De Boer has addressed the problem potentially delaying Airbus A380 operators’ plans to reintroduce the aircraft into their fleets following extended storage during the pandemic. Caused by extreme temperatures and moisture, hydrogen-assisted cracking or hydrogen embrittlement can accelerate the rate at which cracks can form in the A380’s wing’s aluminium alloys.

With a long history of supplying airport expansion and hangar solutions in the Middle East and Europe, Losberger De Boer now offers a new temporary structure large enough to accommodate the A380 aircraft, a new building for the space solutions specialist that is now available in the Middle East and globally for the first time. Modular by design, the 95-metre clearspan space solution represents the evolution of structures that have been used as airport and airfield terminals and hangars. The upsized hangar will be capable of shading one or more A380 aircraft. Open at both ends, the structure can be installed to ensure existing hangars remain easily accessible, providing a flexible solution for storage and light maintenance requirements.

Measuring 95 metres wide by 90 metres long, the bespoke aluminium curved framed shade structure is manufactured off-site, providing an efficient and more sustainable solution compared to traditional, on-site, permanent construction. Once transported to its final destination, the structure can be assembled quickly, meaning the hangar can be operational within as little as four months from order. Should there be a later requirement to move the structure, the hangar is fully demountable, easily stored and can be reassembled at a different location.

The hangar’s PVC roof and polyisocyanurate (PIR) sandwich panels protect the aircraft within the hangar from environmental elements. Delivered turnkey, the structure features overhead fans to cool the air. Losberger De Boer also offers a climate control system, enabling temperature and humidity levels to be set and monitored.

“Heat and humidity have been identified as leading contributing factors of the wing-spar cracking problem reported,” said Paul Machin, Losberger De Boer Middle East’s senior sales manager.

“Providing temporary and semi-permanent space solutions for aircraft owners and operators to meet environmental challenges is not new for Losberger De Boer. We have been providing hangars, industrial hangars and terminals for many years. However, the A380 presented a new challenge, and we are offering this new hangar to offer the same level of quality we are known for on a larger scale. High temperatures and humidity levels in the Middle East, combined with the need for a shaded structure to store and carry out light maintenance, prompted us to bring a solution to the market that could be manufactured and installed in months, rather than years.”

The large-scale hangar does not require traditional foundations, meaning it can be erected and handed over within six weeks following delivery. The curved frame is secured to the existing concrete platform via chemical anchoring. Once disassembled, the site can be returned to its previous state with no need for any rectification works.

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Comments

No comment