Focus Graphite Pilot Run Demonstrates Significant Increase In Large And Jumbo Flake Recovery At Lac Knife

| Specification | DLA Requirement | Focus Graphite - AETC Pilot |

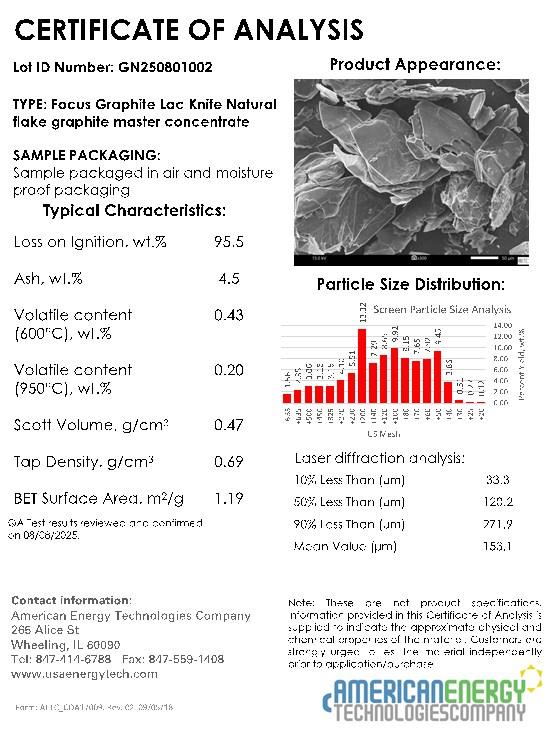

| Fixed Carbon (TGC) | ≥ 94% | 95.5% |

| Ash | ≤ 5% | 4.5% |

| Volatile Matter | ≤ 1.2% | 0.63 wt.% (600 °C) |

| Moisture | ≤ 0.5% | <0.5% |

| Size Distribution | <20% retained above 100 mesh; ≤20% passing below 325 mesh | D10 = 33 μm; D50 = 120 μm; D90 = 272 μm; mean 153 μm |

Table 1: DLA Strategic Materials Program Benchmark vs. Focus Graphite Lac Knife AETC Pilot Results

Note: As of August 2025, The DLA has indicated its intent to source 49,433 tonnes of natural flake graphite over the next five years (CIP-Hammond, Indiana)

Coarse graphite flakes are rare and command premium pricing in markets where physical size is the key differentiator. On October 20, 2023, China announced its restrictions on certain graphite exports to the United States and other counties, with the new regulations taking effect on December 1, 2023. These rules, requiring export permits for high-grade natural and synthetic graphite products, were introduced under the banner of protecting China's national security. Most projects worldwide produce very little of this unique material. With its coarse flake profile, Lac Knife positions Focus to supply several high-margin speciality applications:

- Jumbo flake (+30, +25, +20 mesh; ~5% of total, up to 0.84 mm in size) - High-end EMI shielding in electronics and defense equipment, corrosion resistant gaskets in marine and aerospace, crucibles for specialty alloys and rare earth processing, radar absorbing and steal composites, icephobic for aircraft and ships, precursor for graphene platelets.

+50 mesh (~15%) and +80 mesh (~24%) - Expandable and expanded graphite for fire-suppressant foams. With PFAS-based aqueous film-forming foams (" AFFF "), otherwise known as forever chemicals, being phased out amid billion-dollar lawsuits, demand for safe, graphite-based alternatives is expected to surge. Processed graphite generated from these flake sizes are also used in lead-acid and premium performance alkaline batteries. +100 mesh - Recently proven in a hypersonic rocket nozzle launch, this fraction is valued in aerospace, defense, semiconductor and advanced materials markets.

-100 mesh - Tailored for the battery-grade anode market in both EVs and stationary battery energy storage systems (" BESS ") applications, ensuring compliance with global demand.

Additionally, Lac Knife graphite demonstrates exceptionally low volatile content, a critical property for the most demanding nuclear and defense applications. While many companies can produce standard battery-grade graphite, nature rarely yields deposits with such a high proportion of coarse flakes. Lac Knife's increase in large and jumbo flake recovery from approximately 33% to 47% further strengthens Focus's strategic position. This advantage not only supports advanced processing pathways but also enables the Company to deliver environmentally friendly materials to market, creating opportunities to replace PFAS-based "forever chemicals" with safer, sustainable alternatives.

"The results from this pilot program reinforce Lac Knife's unique position as one of the few graphite projects capable of delivering both defense-grade and battery-grade material at scale," said Dean Hanisch, CEO of Focus Graphite. "By achieving market-aligned concentrate specifications, we are not only positioned to supply the EV and energy storage sectors, but also to serve premium aerospace, defense, and specialty markets. This dual-market advantage reduces risk, expands opportunity, and underscores Focus Graphite's role as a strategic supplier in North America's critical minerals supply chain."

It should be noted that this pilot program was conducted on more than 800 kilograms of Lac Knife graphite, and while the results are consistent with expectations, they may not fully represent the variability of the entire deposit. Focus intends to conduct larger scale testing in the future.

Image 1: Focus Graphite Lac Knife Natural Flake Graphite Master Concentrate, C of A

To view an enhanced version of this graphic, please visit:

Qualified Persons

The technical content disclosed in this news release was reviewed and approved by Réjean Girard, P.Geo. (QC), President of IOS Geosciences Inc., a consultant to the Company, and a qualified person as defined under National Instrument NI-43-101.

About American Energy Technologies Company

American Energy Technologies Co. ("AETC") is a woman-owned, privately held business which conducts operations out of the greater Chicago area. In its Wheeling, IL facility, AETC operates three business units: a manufacturing plant making battery-ready graphite and carbon materials, a pilot demonstration facility for battery materials and graphite dispersions, and a fully-functional applications laboratory supporting the above business units. Currently, AETC is one out of just three in total organizations which commercially manufacture lithium-ion battery-ready graphite in the United States. Furthermore, AETC's Wheeling, IL plant is currently the only industrial end-to-end commercial manufacturer of spherical purified surface coated natural graphite in the US. In doing so, the company develops and operates an upstream ore beneficiation, unique refining, particle spheroidization, and carbon coating technologies. AETC is both developing and produces spherical graphite (natural and synthetic), expanded graphite, partially graphitized nanostructured carbons, ultra-high purity graphite-based electrically conductive inks, paints, and coatings which find use within the industry. AETC is a proud supply chain member of electric vehicles and an approved supplier to twelve battery manufacturers and one fuel cell producer.

For more information, please visit

About Focus Graphite Advanced Materials Inc.

Focus Graphite Advanced Materials is redefining the future of critical minerals with two 100% owned world-class graphite projects and cutting-edge battery technology. Our flagship Lac Knife project stands as one of the most advanced high-purity graphite deposits in North America, with a fully completed feasibility study. Lac Knife is set to become a key supplier for the battery, defense, and advanced materials industries.

Our Lac Tetepisca project further strengthens our portfolio, with the potential to be one of the largest and highest-purity and grade graphite deposits in North America. At Focus, we go beyond mining - we are pioneering environmentally sustainable processing solutions and innovative battery technologies, including our patent-pending silicon-enhanced spheroidized graphite, designed to enhance battery performance and efficiency.

Our commitment to innovation ensures a chemical-free, eco-friendly supply chain from mine to market. Collaboration is at the core of our vision. We actively partner with industry leaders, research institutions, and government agencies to accelerate the commercialization of next-generation graphite materials. As a North American company, we are dedicated to securing a resilient, locally sourced supply of critical minerals - reducing dependence on foreign-controlled markets and driving the transition to a sustainable future.

For more information on Focus Graphite Inc. please visit

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Most popular stories

Market Research

- United States Lubricants Market Growth Opportunities & Share Dynamics 20252033

- UK Digital Health Market To Reach USD 37.6 Billion By 2033

- Immigration Consultancy Business Plan 2025: What You Need To Get Started

- United States Animal Health Market Size, Industry Trends, Share, Growth And Report 2025-2033

- Latin America Mobile Payment Market To Hit USD 1,688.0 Billion By 2033

- United States Jewelry Market Forecast On Growth & Demand Drivers 20252033

Comments

No comment