Copper Fox Completes Preliminary Geometallurgical Model On Van Dyke ISCR Copper Project

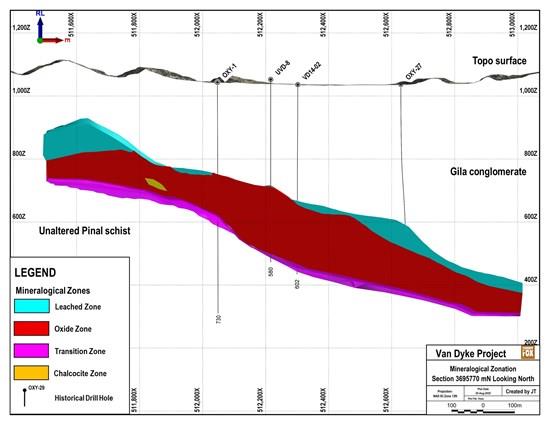

| Mineralogical Zone | Description |

| Leached | Contains variable concentrations of clays and iron-oxides (limonite-hematite-goethite-jarosite). May contain trace concentrations of copper oxide minerals. Typically contains less than 200ppm total copper (TCu). |

| Oxide | Contains variable concentrations of azurite, malachite, and chrysocolla with lesser concentrations of cuprite and native copper. Contains greater than 250ppm acid soluble copper (ASCu) and very low concentrations of cyanide soluble copper (CNCu). |

| Transition | Contains variable concentrations of acid soluble and cyanide soluble copper minerals with gradual transition at depth from ASCu to more CNCu. |

| Chalcocite | Contains CNCu concentrations greater than 0.1%. CNCu concentration is typically three times higher than ASCu concentrations. |

Gap Analysis

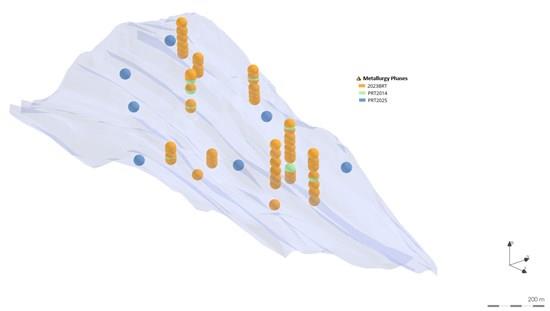

Metallurgical testwork at Van Dyke consists of; eight (8) pressure leach tests (PRT) on whole core samples in 2014 and, 65 bottle roll leach tests (BRT) in 2023 from selected drillholes located within the Phase I leaching plan (year 1-7) set out in the 2020 PEA. Data gaps in the metallurgical database represent potential risk of variability in copper extraction and recovery.

The metallurgical testwork completed on similar deposits in Arizona was used to benchmark mineral characterization, process route selection and assessing processing risks for the Van Dyke project. The data from these tests were correlated spatially to the 2020 resource block model and the mineralogical domains identified within the Van Dyke deposit.

Identification of the data gaps allows for pre-selection of representative sample locations within the mineralogical domains from future drillholes to support an updated geometallurgical model.

Future Testwork Recommendations

Recommendations for additional metallurgical testwork include using whole drill core samples to characterize the mineralization, identify mineralogy, BRT and corresponding PRT tests to establish correlation between the two tests, and their associated residue assays to evaluate/confirm optimum acid addition and consumption, leach cycle duration, and predicted copper extraction (Figure-2).

The closed-cycle PRT tests should include solvent extraction of the pregnant leach solution and detailed mineralogical studies on head samples as well as leach residues for each test. The quantification of carbonates and clays should be performed on head samples.

Figure-2: Plan view of the Van Dyke copper deposit show locations of existing and recommended metallurgical test sample locations. Blue = proposed metallurgical samples; Orange = 2023 BRTs; Green = 2014 PRTs.

To view an enhanced version of this graphic, please visit:

Sampling Protocols

Completion of the PGM established the following protocols for future metallurgical testing:

- Sample preparation and analysis and bottle roll testing on a sub-sample of the head sample. Testing protocols, PRT column height, leach solution chemistry, application rates or additional methods considering hydraulic pressure limits that include the following:

- Consideration of higher initial acid content to improve leach cycle time. Define sequential (multiple columns in series) tests to better understand transmissivity and its impact over time. Consideration of reverse flow test for pH optimization. Consideration of duplicate tests.

- Assay/mineral studies on the leached sample residue.

Qualified Person

Elmer B. Stewart, MSc. P. Geol., President, and CEO of Copper Fox, is the Company's non-independent, nominated Qualified Person pursuant to National Instrument 43-101, Standards for Disclosure for Mineral Projects, and has reviewed and approves the scientific and technical information disclosed in this news release.

About Copper Fox

Copper Fox is a Canadian resource company focused on copper exploration and development in Canada and the United States. The principal assets of Copper Fox and its wholly owned subsidiaries, being Desert Fox Copper Inc., and Northern Fox Copper Inc. are the 100% ownership of the Van Dyke oxide copper project located in Miami, AZ, the 100% interest in the Mineral Mountain and Sombrero Butte porphyry copper exploration projects located in Arizona, the 25% interest in the Schaft Creek Joint Venture with Teck Resources Limited on the Schaft Creek copper-gold-molybdenum-silver project and the 100% owned Eaglehead polymetallic porphyry copper project each located in northwestern British Columbia. For more information on Copper Fox's mineral properties and investments visit the Company's website at .

On behalf of the Board of Directors,

Elmer B. Stewart

President and Chief Executive Officer

Legal Disclaimer:

MENAFN provides the

information “as is” without warranty of any kind. We do not accept

any responsibility or liability for the accuracy, content, images,

videos, licenses, completeness, legality, or reliability of the information

contained in this article. If you have any complaints or copyright

issues related to this article, kindly contact the provider above.

Most popular stories

Market Research

- United States Lubricants Market Growth Opportunities & Share Dynamics 20252033

- UK Digital Health Market To Reach USD 37.6 Billion By 2033

- Immigration Consultancy Business Plan 2025: What You Need To Get Started

- United States Animal Health Market Size, Industry Trends, Share, Growth And Report 2025-2033

- Latin America Mobile Payment Market To Hit USD 1,688.0 Billion By 2033

- United States Jewelry Market Forecast On Growth & Demand Drivers 20252033

Comments

No comment